Method for calibrating drop hammer volume

A calibration method and the technology of the pendant, which are applied in the direction of material analysis by measuring buoyancy, can solve the problems of not meeting the needs of fuel standard density measurement, large volume errors, etc., to meet the needs of performance testing, accurate and reliable volume calibration, avoid effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

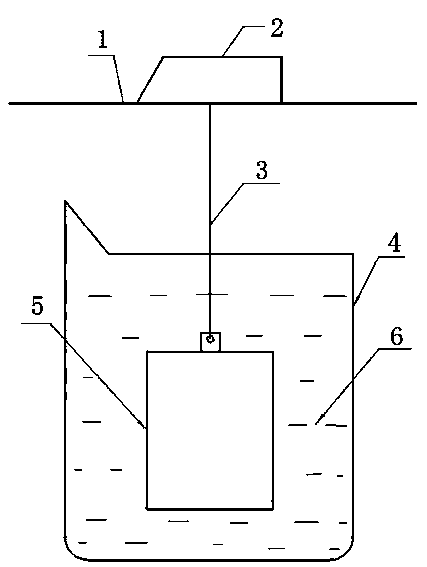

[0028] see figure 1 , the method for calibrating the volume of the pendant hammer, is characterized in that: comprising the following steps:

[0029] S1, in a relatively stable temperature test environment, clean the pendant 5 with pure water 6 and dry it for later use, place the analytical balance 2 on the support platform 1 and adjust it to a horizontal state for later use; put the pendant 5 with a purity of not less than 98% The pure water 6 that can fully immerse the pendant is poured into the beaker 4 for subsequent use;

[0030] S2, turn on the power of the analytical balance 2, and use the calibration weights of the analytical balance 2 to calibrate;

[0031] S3, placing the pendant 5 on the analytical balance 2 after calibration and weighing, the reading value recorded after the reading of the analytical balance 2 is stable, the reading value is the mass m of the pendant 5 in the air 空气 ;

[0032] S4, put the pendant 5 into the beaker 4 equipped with pure water 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com