Equipment and method for synchronous thaw settlement grouting during unfreezing

A technology of melting and sinking grouting and grouting, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of high construction risk, tunnel deformation, body settlement, etc., and achieve the effect of reducing risks and shortening the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

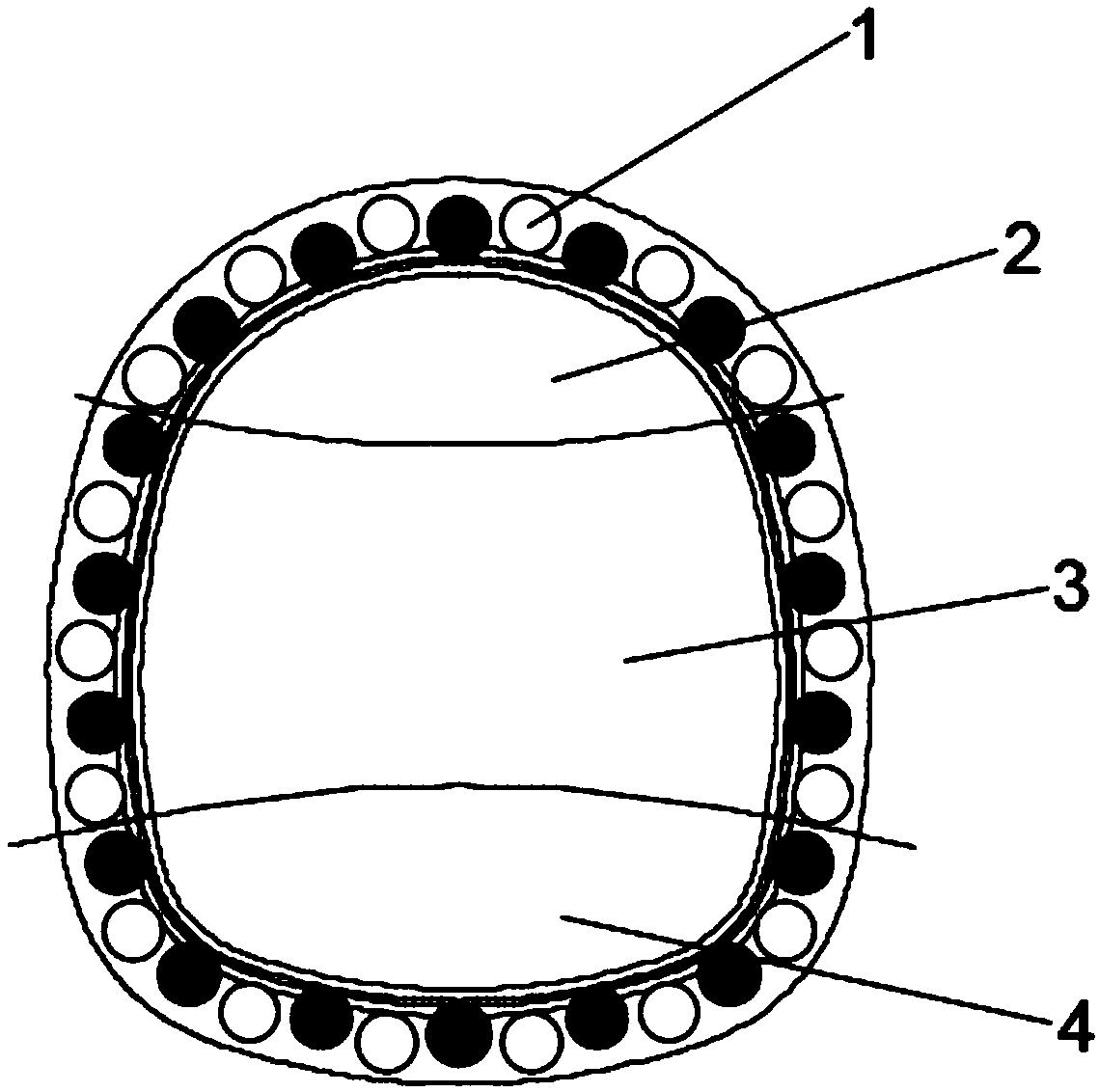

[0024] Such as Figure 1-3 As shown, a device and method for synchronous thawing and grouting during thawing uses pipe curtains to pre-support frozen soil. The pipe curtains are composed of 36 numbered steel pipes 1 from No. 1 to No. 36, and the odd-numbered pipes are filled with concrete The actual pipes, the even pipes are empty pipes, and the even numbers are the main construction areas for grouting in the later stage; 36 numbered steel pipes 1 divide the permafrost area into A frozen area 2, B frozen area 3 and C frozen area 4, and the The numbered steel pipes 1 in the A freezing area 2 are No. 1-6 and No. 32-36, the numbered steel pipes 1 in the B freezing area 3 are No. 7-12 and 26-31, and the C freezing The numbered steel pipes 1 in zone 4 are No. 13-25.

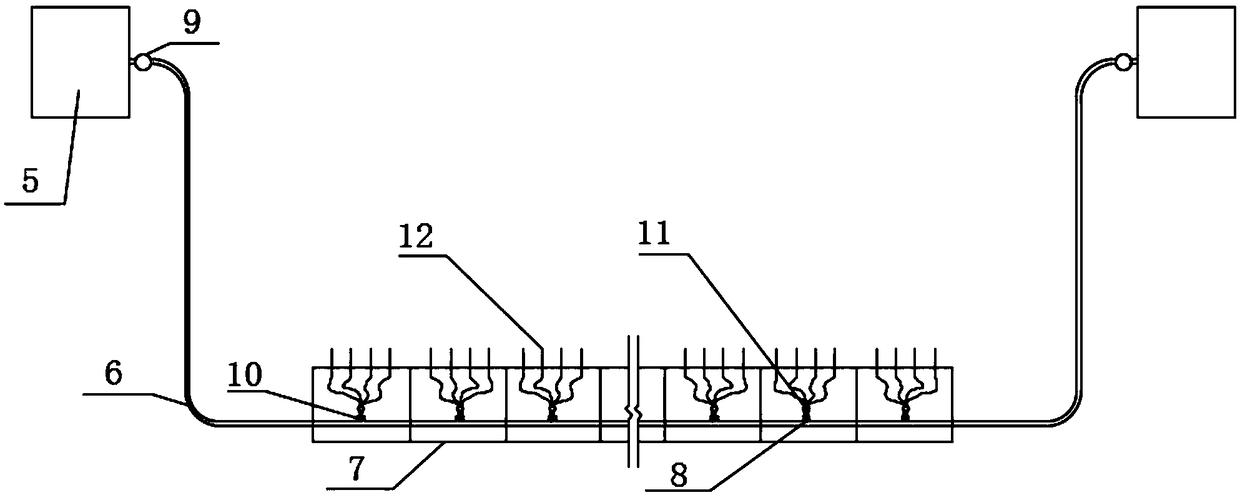

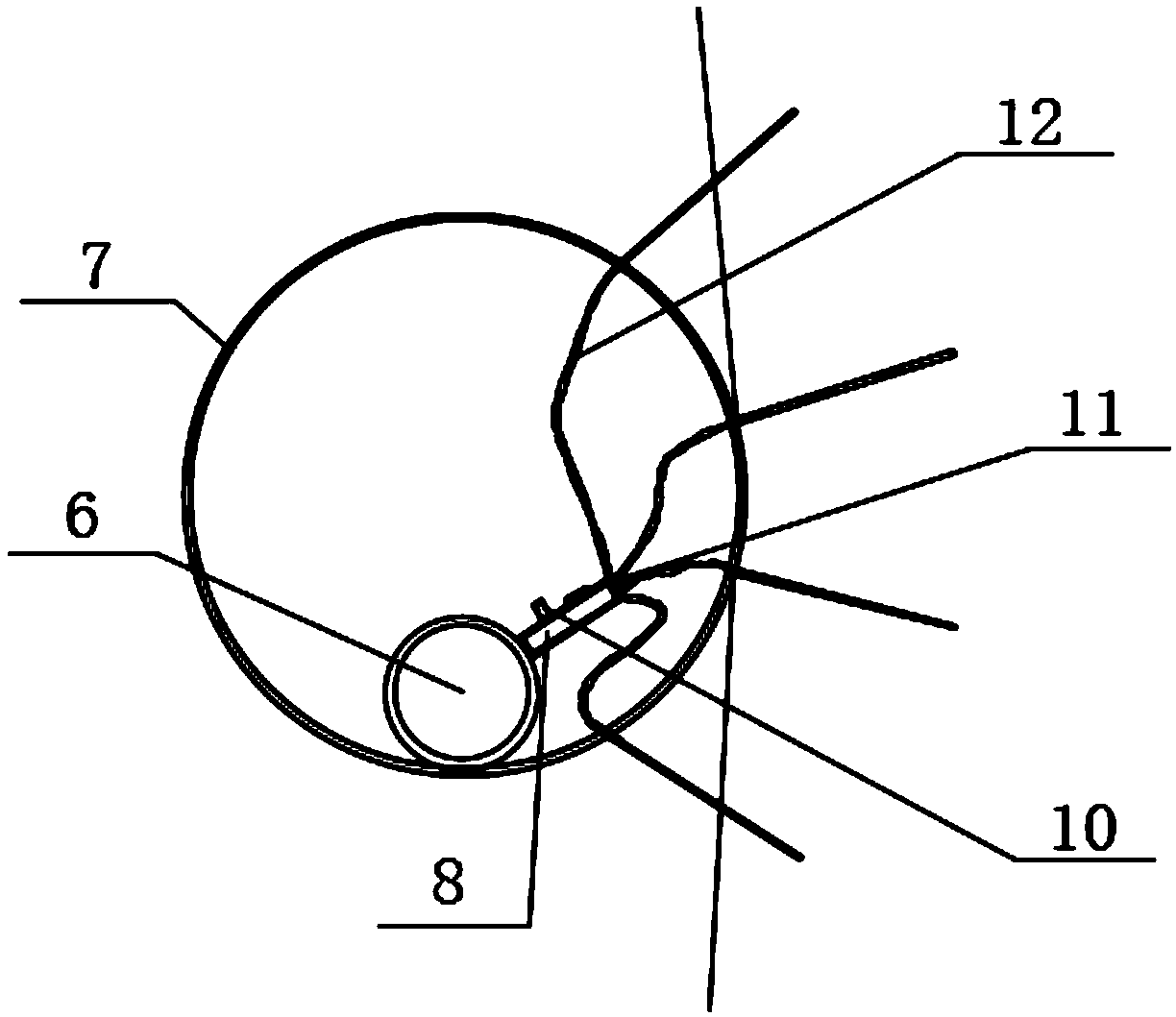

[0025] There are symmetrical jacking pipes 7 inside the permafrost, and two sets of grouting machines 5 are arranged in the working wells on both sides. The grouting pumps in the grouting machines 5 are hydraulic dou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com