Optical anti-forgery ink with red, green and blue long-life luminescent characteristics and preparation method and application thereof

A technology with luminous characteristics and optical anti-counterfeiting, which is applied in the field of optical anti-counterfeiting ink and its preparation, can solve the problems of limited application, achieve high-throughput information encryption, realize the effect of flux information encryption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

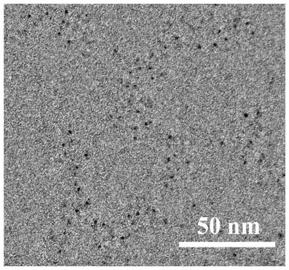

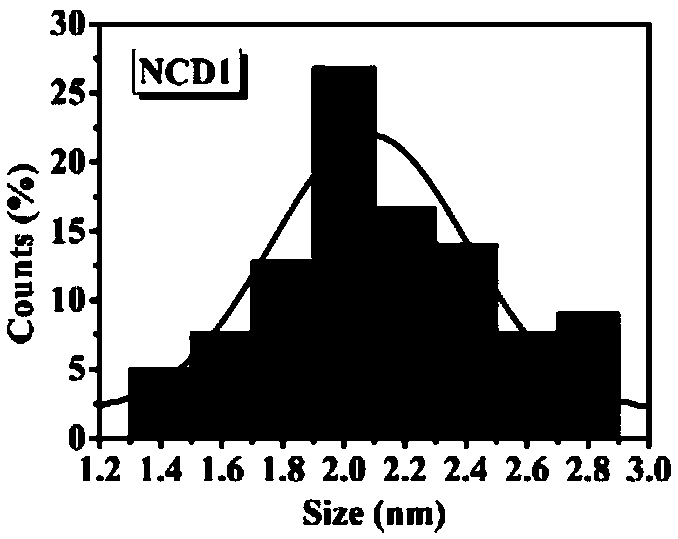

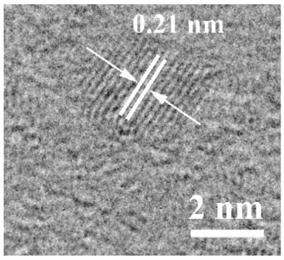

[0039] Preparation of carbon dot 1 (NCD1)

[0040] Weigh 1 g of folic acid and evenly disperse it in 30 mL of absolute ethanol, and stir for 10 min. The above dispersion liquid was transferred to a 100mL polytetrafluoroethylene-lined stainless steel reaction kettle, the lid of the kettle was tightened, and the reaction temperature was 260°C, and the hydrothermal reaction was carried out for 2 hours. The reactor was naturally cooled to room temperature, and the product was centrifuged at a speed of 11000 r / min for 10 min to filter off the supernatant to obtain a crude product. The crude product was put into a vacuum oven, and dried under vacuum at 80° C. for 6 h. Weigh 50 mg of solid powder and dissolve it in 10 mL of deionized water to obtain a 5 mg / mL carbon dot 1 dispersion.

[0041] Preparation of carbon dot 1 composite powder (NCD1-C)

[0042] Dissolve 6 g of urea in 3 mL of carbon dot 1 dispersion, add 3 mL of deionized water, and sonicate for 10 min to obtain a unifor...

Embodiment 2

[0047] Preparation of carbon dots 2 (NCD2)

[0048] Weigh 0.3 g of folic acid and disperse it in 30 mL of deionized water, and stir for 10 min. The above dispersion liquid was transferred to a 100mL polytetrafluoroethylene-lined stainless steel reaction kettle, the lid of the kettle was tightened, and the reaction temperature was 260°C, and the hydrothermal reaction was carried out for 2 hours. The reactor was naturally cooled to room temperature, and the product was centrifuged at a speed of 11000 r / min for 10 min to filter out the precipitate, and the supernatant was taken. The supernatant was freeze-dried to obtain a solid powder. Weigh 50 mg of solid powder and dissolve it in 10 mL of deionized water to obtain a 5 mg / mL carbon dot 2 dispersion.

[0049] Preparation of carbon dots 2 composite powder (NCD2-C)

[0050] Dissolve 6 g of urea in 3 mL of carbon dot 2 dispersion, add 3 mL of deionized water, and sonicate for 10 min to obtain a uniform reaction mixture. The mix...

Embodiment 3

[0055] Preparation of carbon dots 3 (NCD3)

[0056] Weigh 0.3g of o-phenylenediamine and 300μL of ethylenediamine and evenly disperse in 30mL of absolute ethanol, and stir for 10min. The above dispersion liquid was transferred to a 100mL polytetrafluoroethylene-lined stainless steel reaction kettle, the lid of the kettle was tightened, and the reaction temperature was 180°C for hydrothermal reaction for 12 hours. Let the reactor cool down to room temperature naturally, put the product into a dialysis bag with a molecular weight of 500, and fully dialysis for 48 hours. A dispersion of about 5 mg / mL carbon dot 3 was obtained.

[0057] Preparation of carbon dot 3 composite powder (NCD3-C)

[0058] Dissolve 6 g of urea in 3 mL of carbon dot 3 dispersion, add 3 mL of deionized water, and sonicate for 10 min to obtain a uniform reaction mixture. The mixture was placed in a dry box and reacted at 155°C for 6h. After natural cooling to room temperature, the carbon dots 3 composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com