Airship nose cone locking device

A locking device and nose cone technology, applied in aircraft, transportation and packaging, lighter-than-air aircraft, etc., can solve problems such as airship product damage, improve safety, reduce feather resistance, and avoid locking damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

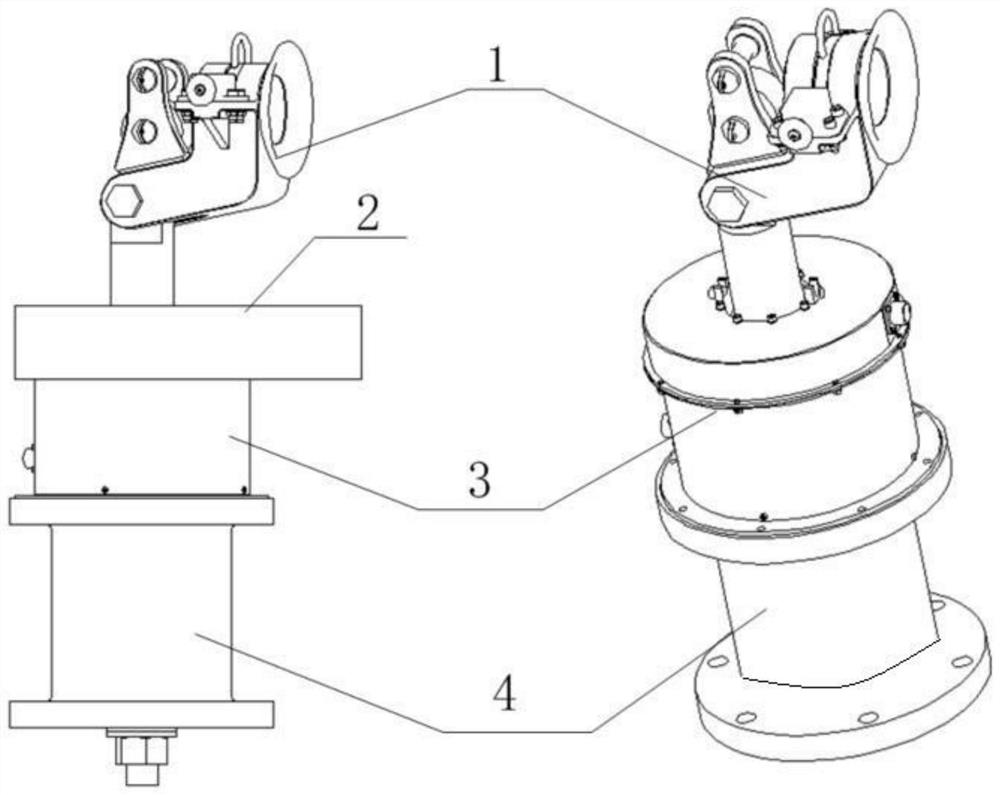

[0028] Such as figure 1 as shown, figure 1 It is a structural view of the airship nose cone locking device of the present invention; the airship nose cone locking device of the present invention includes a locking mechanism 1, a protective cover 2, a slip ring 3, and a rotating device 4; the locking mechanism 1 and the rotating device 4 connection, to ensure that the locking mechanism 1 can be rotated and adjusted; The confluence ring 3 ensures the safe installation of the power supply cable in the airship nose cone locking device, avoiding the power supply cable from winding around the mooring tower; the protective cover 2 is arranged on the confluence ring 3 to prevent rainwater and sand from entering the In the confluence ring 3 described above.

[0029] Through the design of the rotating device 4, the 360° forward and reverse continuous rotation of the locking mechanism 1 can be guaranteed, and the self-adaptive feathering ability of the airship when moored on the ground...

Embodiment 2

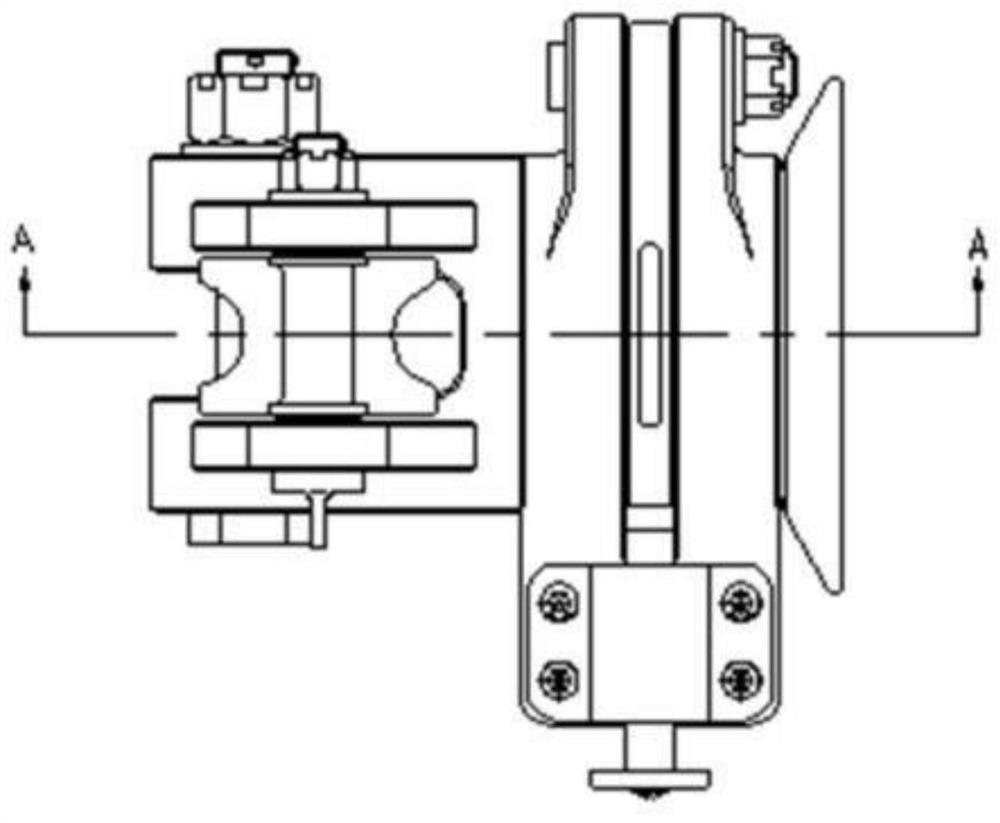

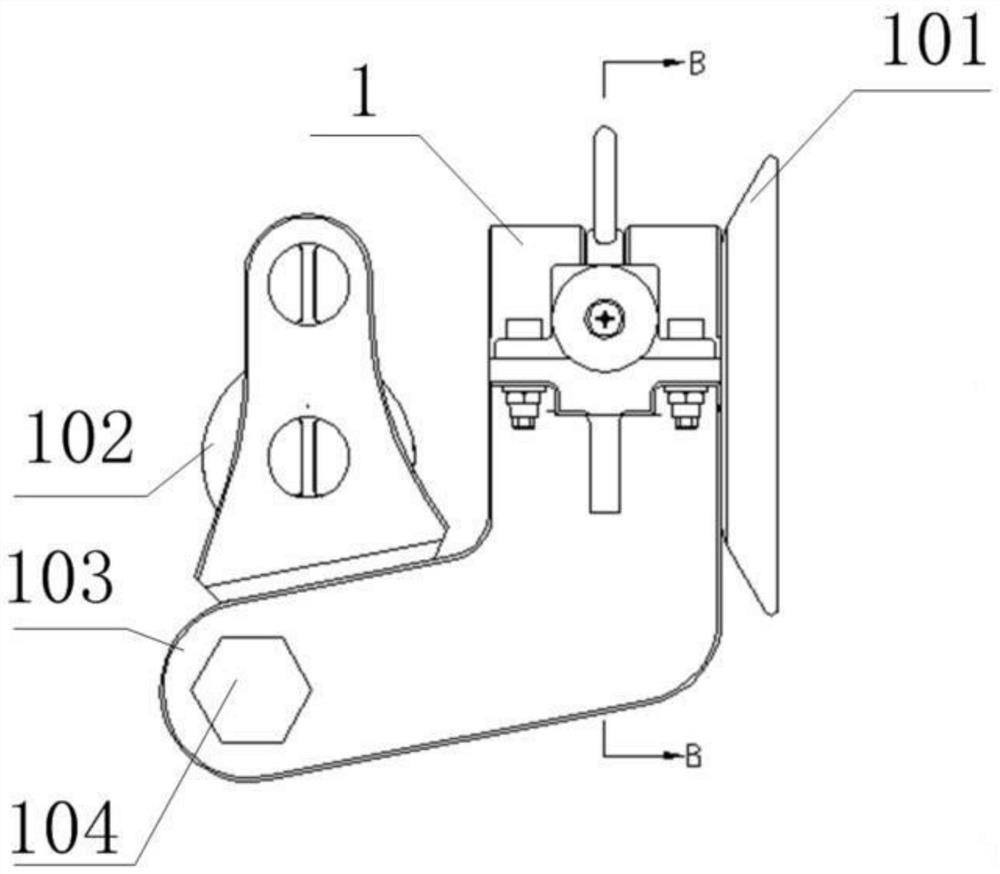

[0031] Such as Figure 2 to Figure 5 as shown, figure 2 is a top view of the locking mechanism; image 3 is the front view of the locking mechanism; Figure 4 for figure 2 The cross-sectional view of A-A in the middle; Figure 5 for image 3 Sectional view of B-B in middle. The locking mechanism 1 is configured as a combined nose cone mooring tube locking mechanism for locking the nose cone of the airship. The locking mechanism 1 includes a nose cone guide port 101, a head rope guide wheel 102, a locking support 103, a pitch rotation shaft 104, a locking gate 105, a lock spring 106, a lock cylinder fixing seat 107, a lock cylinder 108, and a head rope Anti-off shaft 109.

[0032] The locking support 103 is the main load-bearing part of the airship nose cone locking, and the locking support 103 is provided with a hole corresponding to the position of the nose cone guide port 101, and the hole and the nose cone The interior of the guide port 101 is connected; the airsh...

Embodiment 3

[0041] Such as Figure 6 as shown, Figure 6 It is a structural schematic diagram of the slip ring; the slip ring 3 is set as a device that can rotate and conduct current, including a rotor 301, a stator 302, a power input connector 303, a power output connector 304, and a rotor drive connection groove 305; The stator 302 is fixed on the rotating support 406 of the rotating device 4 by bolts, the rotor driving connecting groove 305 is arranged on the upper end surface of the rotor 301, and the rotor 301 passes through the rotor driving connecting groove 305 is connected to the rotor driving rod 402 of the rotating device 4, the stator 302 is connected to the rotating support 406 and fixed, and the rotor 301 rotates with the rotor driving rod 402 of the rotating device 4 The power input connector 303 is set on the stator 302, and the power output connector 304 is set on the rotor 301. When the input power is connected to the power input connector 303, it is connected out from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com