Automatic customized robot for wind power generation industry

A robot and industry technology, applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., can solve the problems of inconvenient disassembly and assembly, reduce customization and assembly efficiency, and achieve convenient lubrication, solve inconvenient assembly, and avoid shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

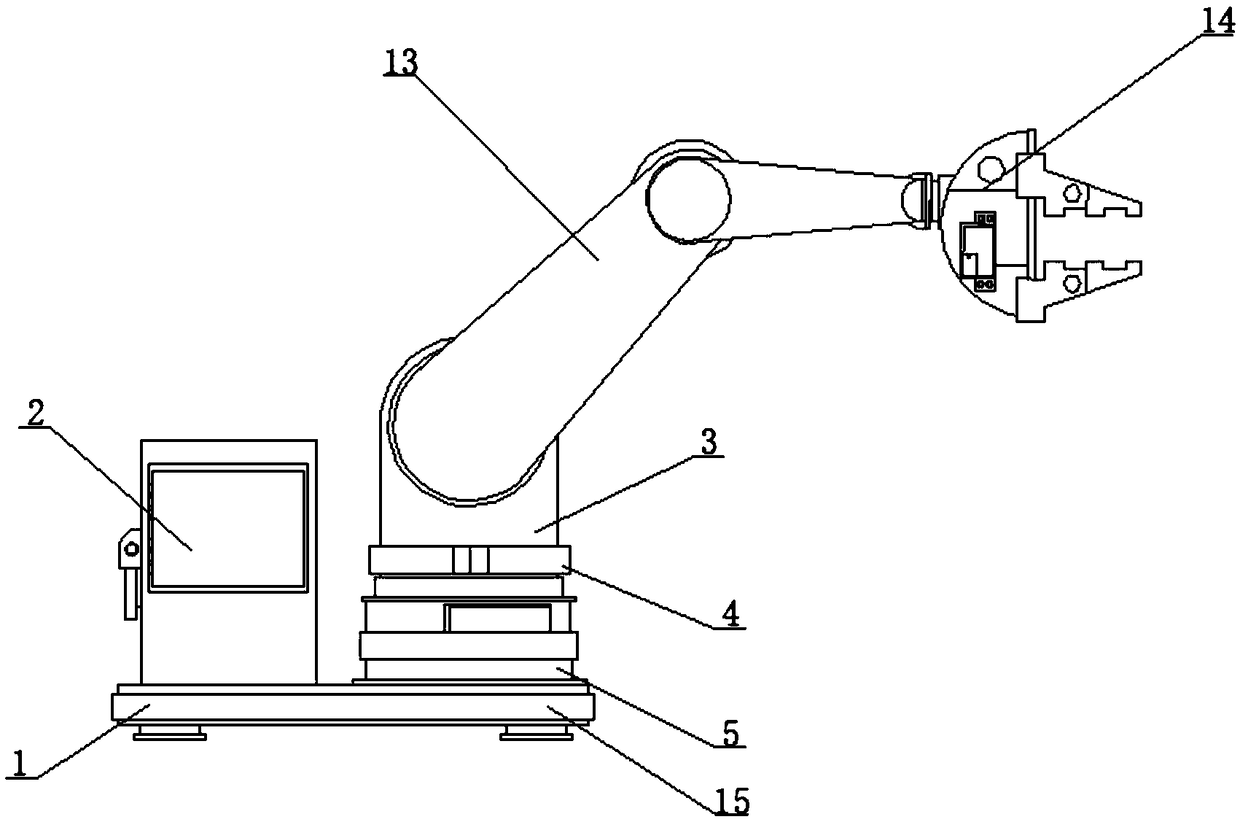

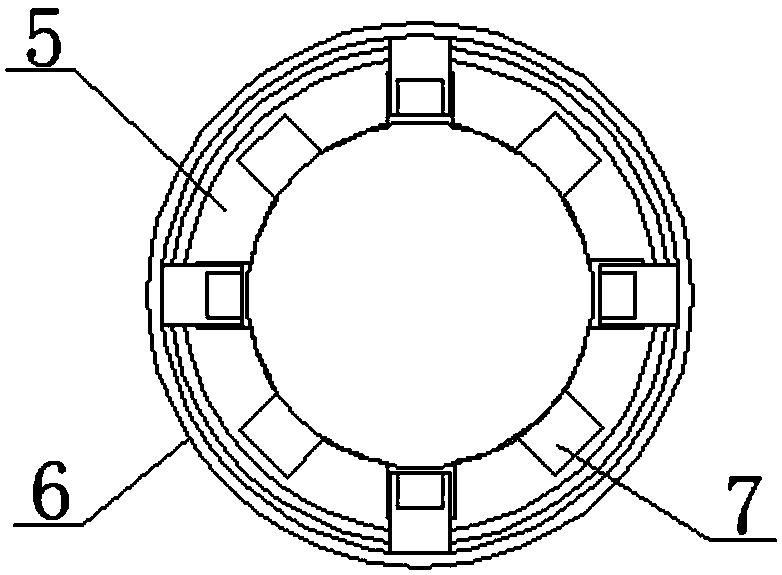

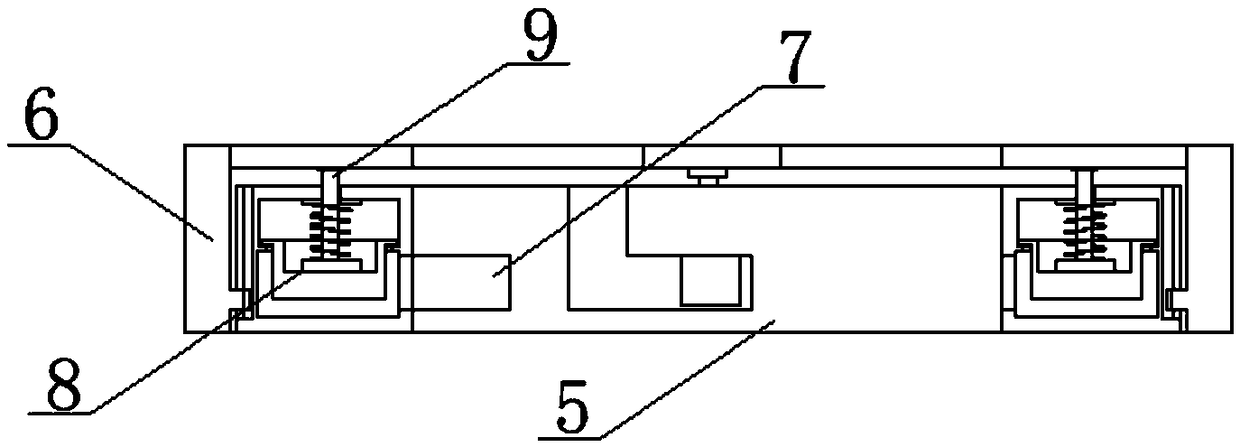

[0020] see Figure 1-Figure 4 , the present invention provides a technical solution: an automated customized robot for the wind power industry, including a customized robot outer shell 15, and also includes a mounting mechanism and a lubrication mechanism. The bottom of the customized robot outer shell 15 is fixedly provided with an operating load-bearing plate 1. The front surface of the robot outer shell 15 is fixedly provided with a load-bearing fixing seat 3, and the installation mechanism includes a connecting chassis 5, a lifting snap ring 6, a fixing slot 7, a stop clip 8 and a connecting guide post 9, and the top of the load-bearing plate 1 is operated. The bottom of the corresponding load-bearing fixing seat 3 is fixedly provided with a connection chassis 5, and the operation load-bearing plate 1 and the connection chassis 5 are of an integrated structure, which greatly increases the stability of the connection between the operation load-bearing plate 1 and the connect...

Embodiment 2

[0026] see Figure 1-Figure 4 , the present invention provides a technical solution: an automated customized robot for the wind power industry, including a customized robot outer shell 15, and also includes a mounting mechanism and a lubrication mechanism. The bottom of the customized robot outer shell 15 is fixedly provided with an operating load-bearing plate 1. The front surface of the robot outer shell 15 is fixedly provided with a load-bearing fixing seat 3, and the installation mechanism includes a connecting chassis 5, a lifting snap ring 6, a fixing slot 7, a stop clip 8 and a connecting guide post 9, and the top of the load-bearing plate 1 is operated. The bottom of the corresponding load-bearing fixing seat 3 is fixed with a connecting chassis 5 by bolts, which greatly facilitates the replacement of the connecting chassis 5. The inner side of the connecting chassis 5 is provided with a fixed card slot 7, and the outer side of the connecting chassis 5 is set by sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com