Method and device for plastically connecting metal pipes and plates with one another

A technology for metal pipes and plates, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of difficult connection between pipes and plates, poor repeatability, low production efficiency, etc., and achieve green plastic connection and compatibility Good, easy to process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

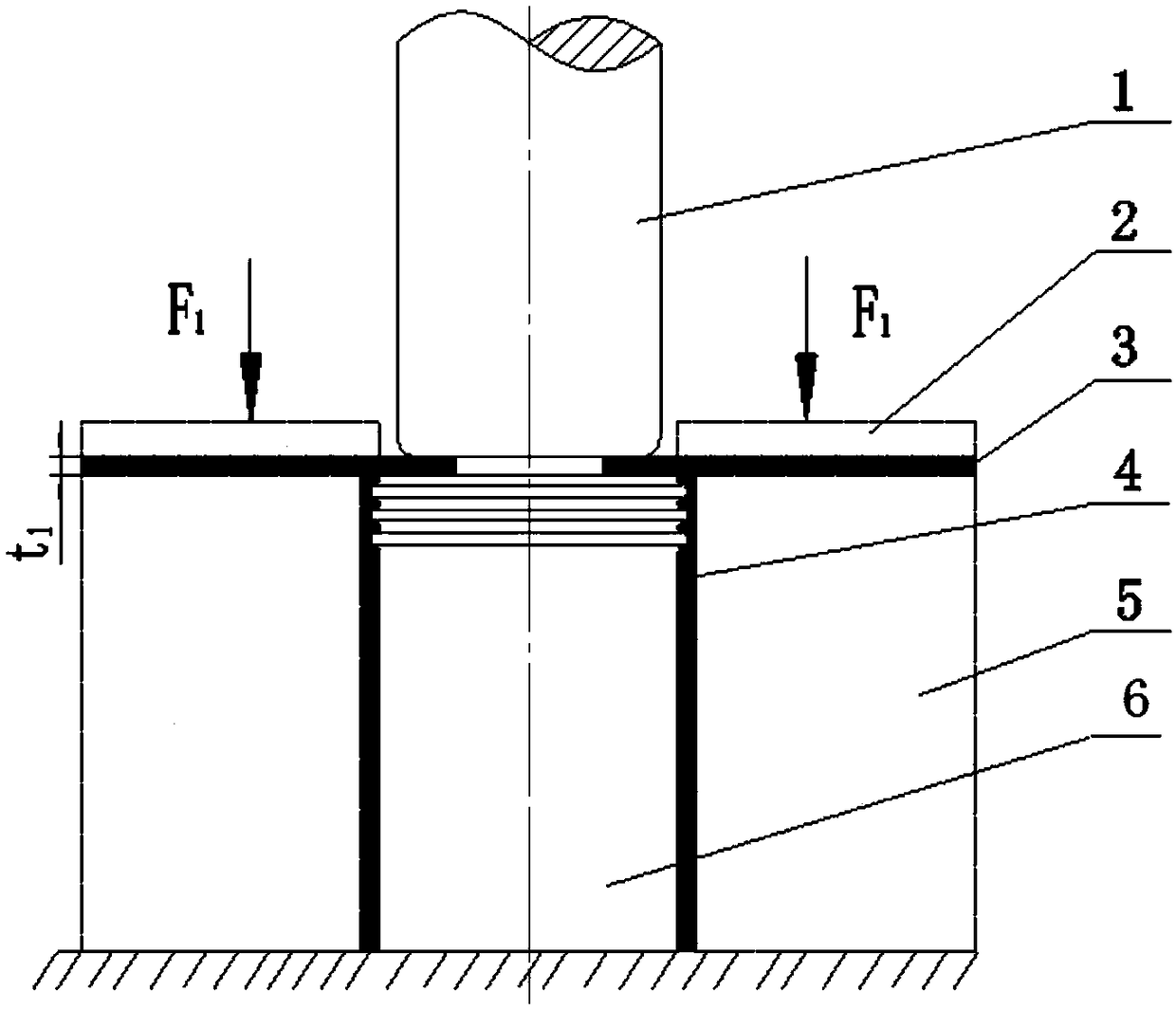

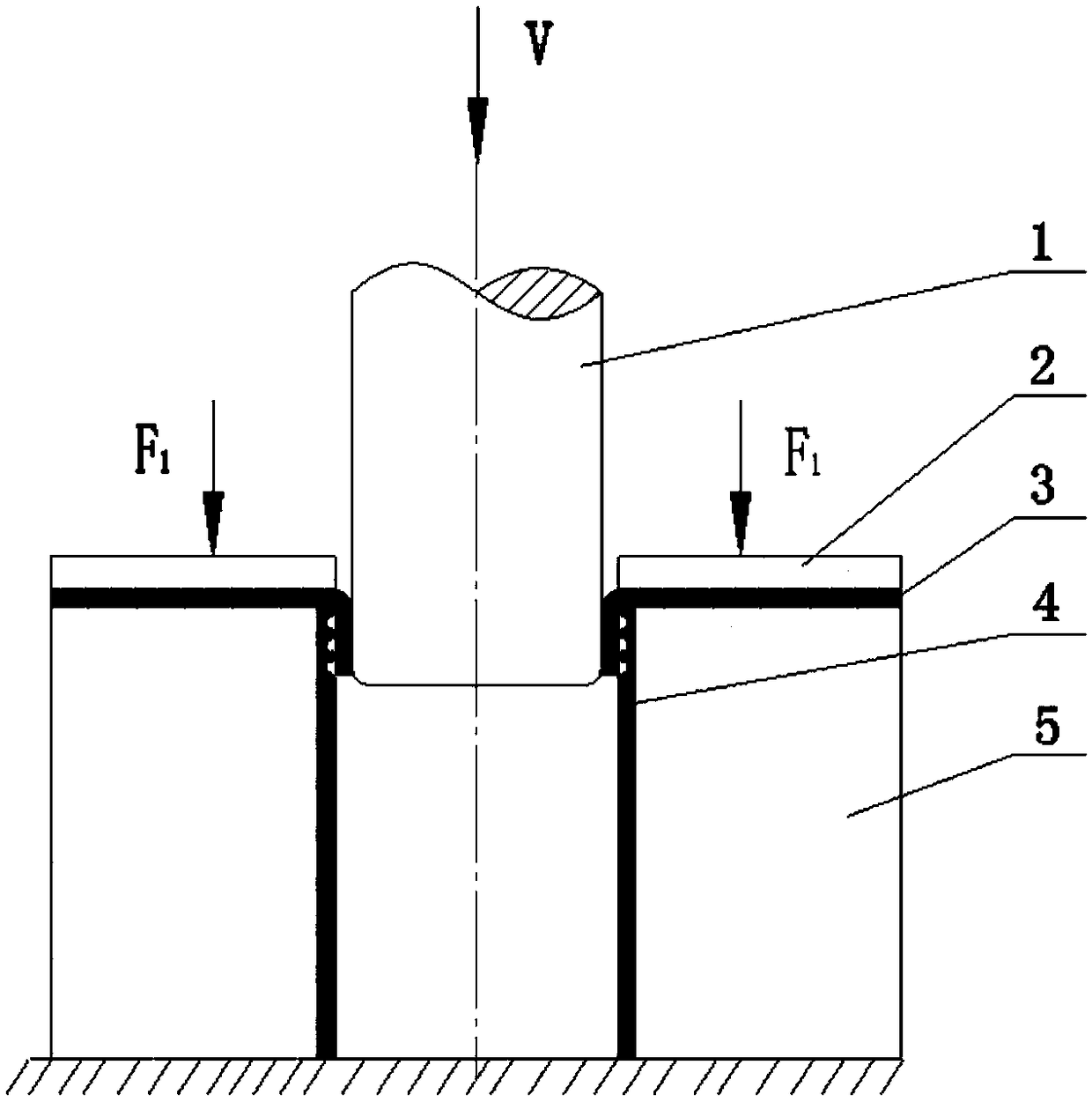

[0035] like figure 1 As shown, the plastic connection device between the metal pipe and the plate of the present invention includes a punch 1, a blank holder 2 and a die 5; the punch 1 is a cylinder, and the front end can preferably be made into a cone or a sphere, and the die 5 is provided with a hole 6 for placing and fixing the pipe material 4, and the pipe material 4 and the hole 6 have an interference fit to achieve the effect of fixing the pipe material 4; Fix the pipe 4 with a diameter in a certain numerical range, and it is easy to assemble and disassemble, saving cost. There is a round hole on the blank holder 2, and the plate 3 can be fixedly placed between the upper plane of the die 5 and the lower plane of the blank holder 2, and the die 5 can be placed on the processing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com