A system and method for cleaning oil stains for intelligent mechanical maintenance

A technology of intelligent machinery and cleaning methods, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc. Instability and other problems, to achieve the effect of easy normal work, low power consumption, and fast adjustment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0050] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

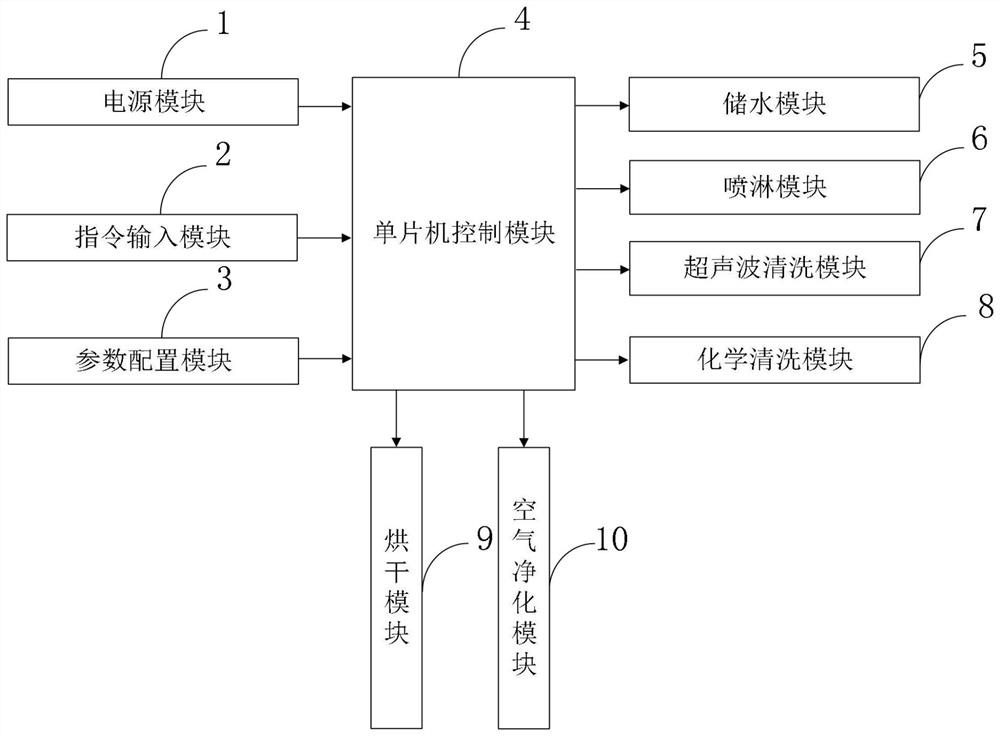

[0051] Such as figure 1 As shown, the oil pollution cleaning system for intelligent mechanical maintenance provided by the present invention includes: a power supply module 1, an instruction input module 2, a parameter configuration module 3, a single-chip microcomputer control module 4, a water storage module 5, a spray module 6, an ultrasonic cleaning module 7, Chemical cleaning module 8, drying module 9, air purification module 10.

[0052] The power supply module 1 is connected with the single-chip microcomputer control module 4, and is used to supply power to each working module;

[0053] The instruction input module 2 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com