Marinated meat product and production processing method thereof

A processing method and technology for braised meat, applied in the field of braised meat processing, can solve the problems of inability to achieve product color, consistency, and high cost, and achieve the effects of good market prospects, improved taste, and consistent color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

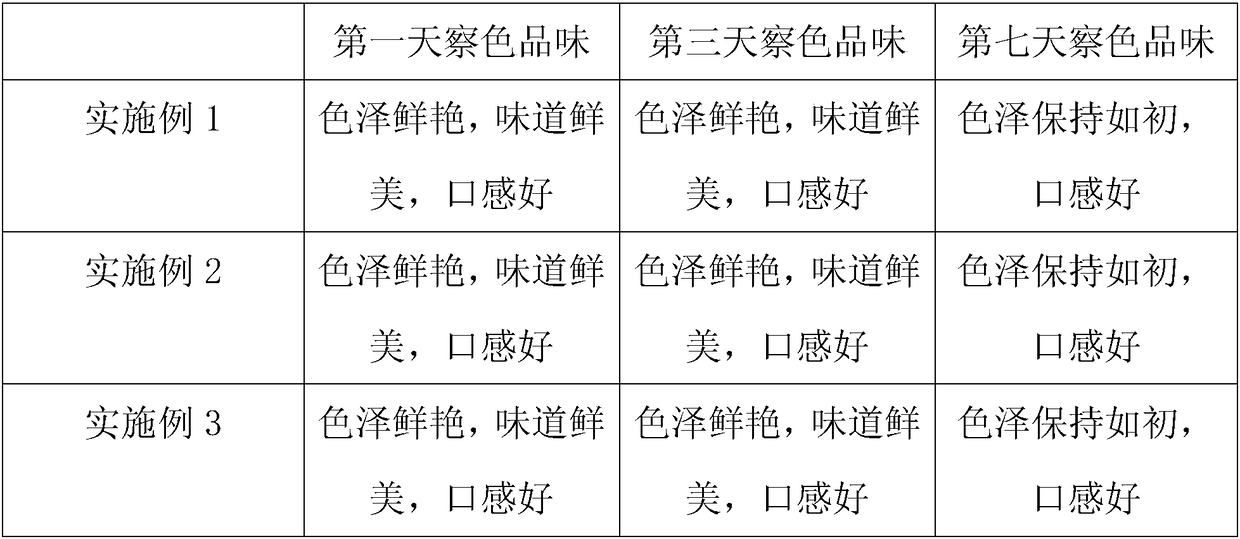

Embodiment 1

[0024] A stewed meat product, consisting of the following raw materials in parts by weight:

[0025] 800 parts of raw meat, 5 parts of sorghum red pigment, 10 parts of rice wine, 15 parts of vinegar, 5 parts of edible salt, 12 parts of ginger slices, 3 parts of Chinese prickly ash, 5 parts of star anise, 10 parts of cinnamon, and 8 parts of minced garlic.

[0026] A method for producing and processing stewed meat products, comprising the steps of:

[0027] S1. Material selection and cleaning: select pork hind legs, in which the weight ratio of fat meat to lean meat is 1:2, shave off the pig hair on the surface of the fat meat, and clean the meat;

[0028] S2. Precooking: add an appropriate amount of water to the pot, heat it to 75°C, then put the meat in S1 into the pot, keep the temperature, cook for 5 minutes, take it out, and seep out the blood in the meat itself in the form of blood foam , to achieve the initial deodorization effect;

[0029] S3, slicing: Slice the preco...

Embodiment 2

[0038] A stewed meat product, consisting of the following raw materials in parts by weight:

[0039] 900 parts of raw meat, 8 parts of sorghum red pigment, 15 parts of rice wine, 20 parts of vinegar, 7 parts of edible salt, 15 parts of ginger slices, 4 parts of Chinese prickly ash, 7 parts of star anise, 12 parts of cinnamon, and 10 parts of minced garlic.

[0040] A method for producing and processing stewed meat products, comprising the steps of:

[0041] S1. Material selection and cleaning: select pork hind legs, in which the weight ratio of fat meat to lean meat is 1:2, shave off the pig hair on the surface of the fat meat, and clean the meat;

[0042] S2. Pre-cooking: add an appropriate amount of water to the pot, heat it to 80°C, then put the meat in S1 into the pot, keep the temperature, cook for 6 minutes, take it out, and seep out the blood in the meat itself in the form of blood foam , to achieve the initial deodorization effect;

[0043] S3, slicing: Slice the pre...

Embodiment 3

[0052] A stewed meat product, consisting of the following raw materials in parts by weight:

[0053] 1000 parts of raw meat, 10 parts of sorghum red pigment, 20 parts of rice wine, 25 parts of vinegar, 8 parts of edible salt, 18 parts of ginger slices, 5 parts of Chinese prickly ash, 8 parts of star anise, 15 parts of cinnamon, and 12 parts of minced garlic.

[0054] A method for producing and processing stewed meat products, comprising the steps of:

[0055] S1. Material selection and cleaning: select pork hind legs, in which the weight ratio of fat meat to lean meat is 1:2, shave off the pig hair on the surface of the fat meat, and clean the meat;

[0056] S2. Precooking: add an appropriate amount of water to the pot, heat it to 85°C, then put the meat in S1 into the pot, keep the temperature, cook for 7 minutes, take it out, and seep out the blood in the meat itself in the form of blood foam , to achieve the initial deodorization effect;

[0057] S3, slicing: Slice the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com