A threshing device for a combine harvester

A combine harvester and threshing device technology, applied in threshing equipment, agricultural machinery and tools, agriculture, etc., can solve the problems of easy wear of rubber or silica gel coating, damage of threshing mechanism, affecting threshing effect and service life, etc. It is not easy to achieve Damage prevention, clogging prevention, anti-clogging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

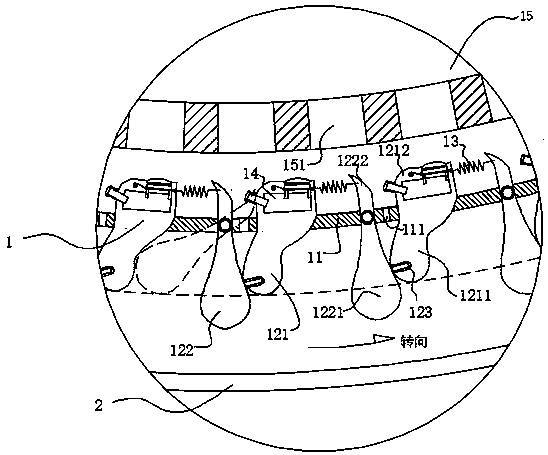

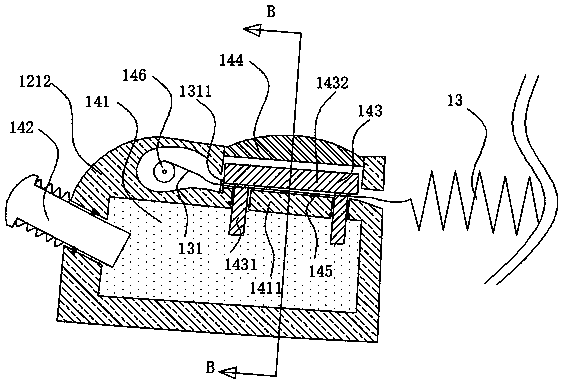

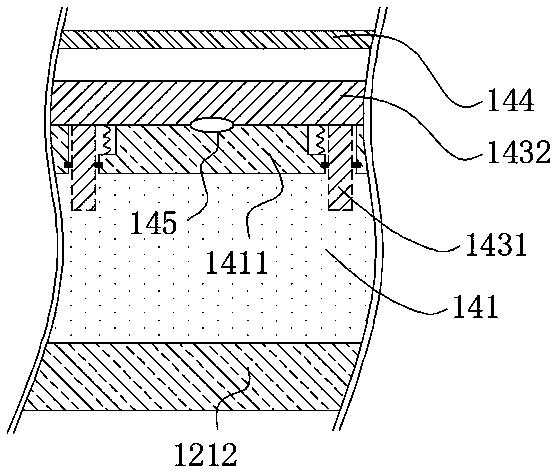

[0023] Such as Figure 1-3 shown

[0024] A threshing device for a combine harvester, comprising a threshing cylinder 1 and a sieve plate 2 matched with the threshing cylinder 1. The threshing cylinder 1 includes a cylinder wall 11, and a plurality of rows of threshing columns 12 uniformly arranged along the circumference of the cylinder wall 11, connecting adjacent The first spring 13 of the threshing column 12, the first spring 13 is a tension spring; the threshing column 12 includes a static column 121 fixedly arranged on the cylinder wall 11, a movable column 122 arranged on the cylinder wall 11 axially hinged, and a movable column 122 A threshing column 12 is formed with a static column 121, and the moving column 122 is not integrated with the static column 121, the moving column 122 is located at the upstream of the rotating direction of the threshing cylinder 1, and the static column 121 is located at the downstream of the rotating direction of the threshing cylinder 1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com