direct current brushless motor which saves the debugging process of a Hall position sensor

A brushless DC motor, Hall position technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of interference, heat generation, complex craftsmanship, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

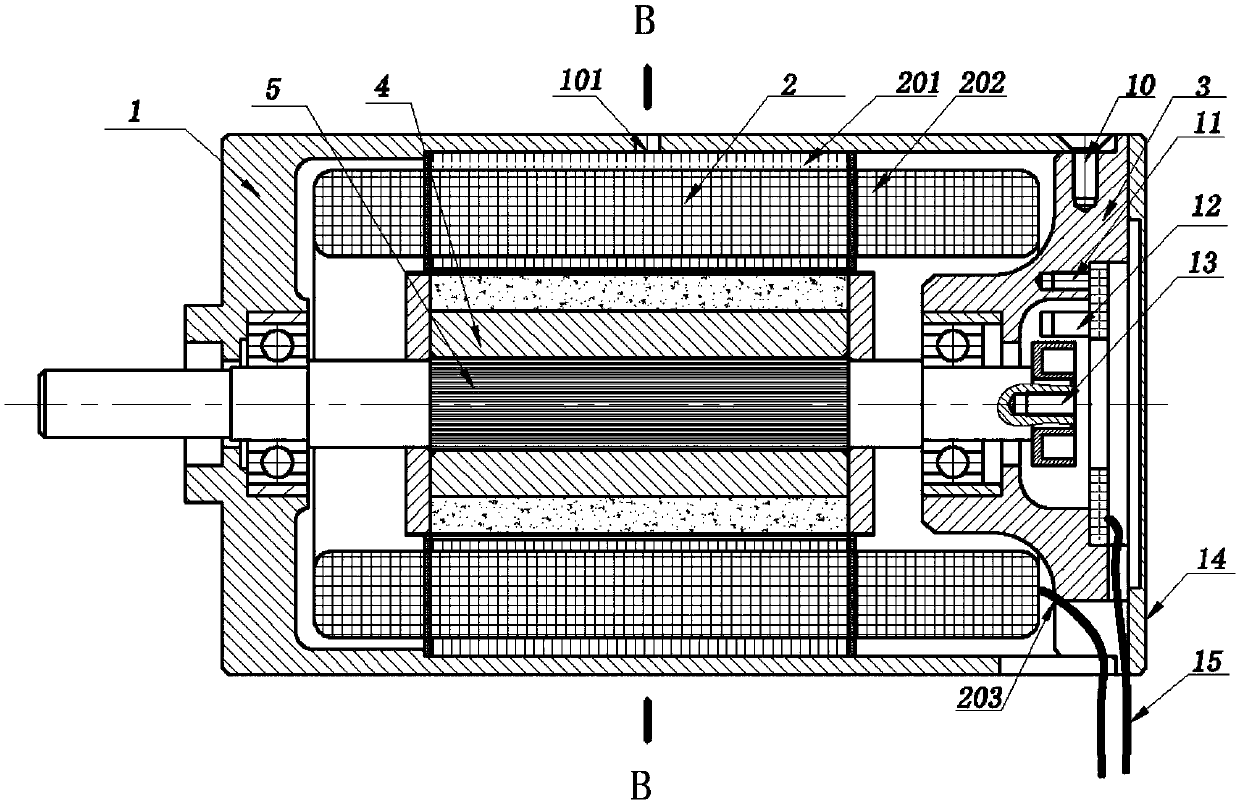

[0027] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

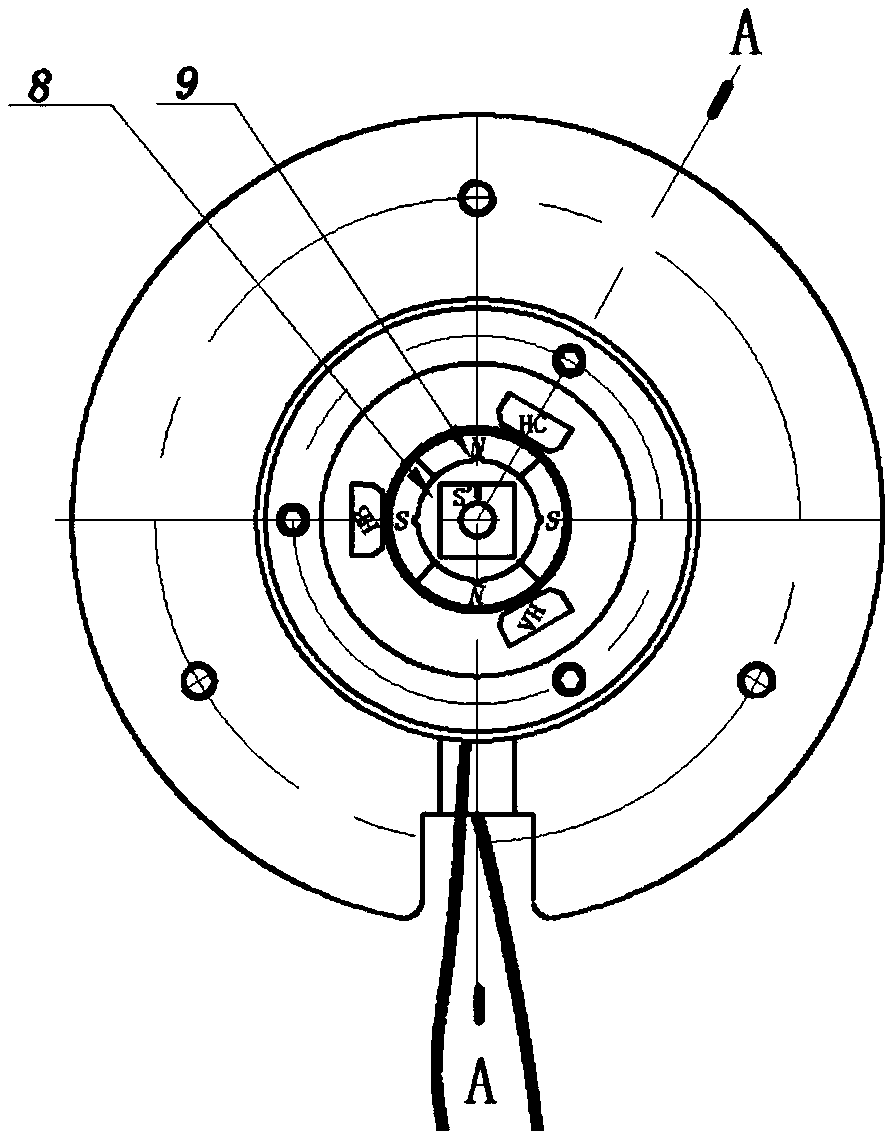

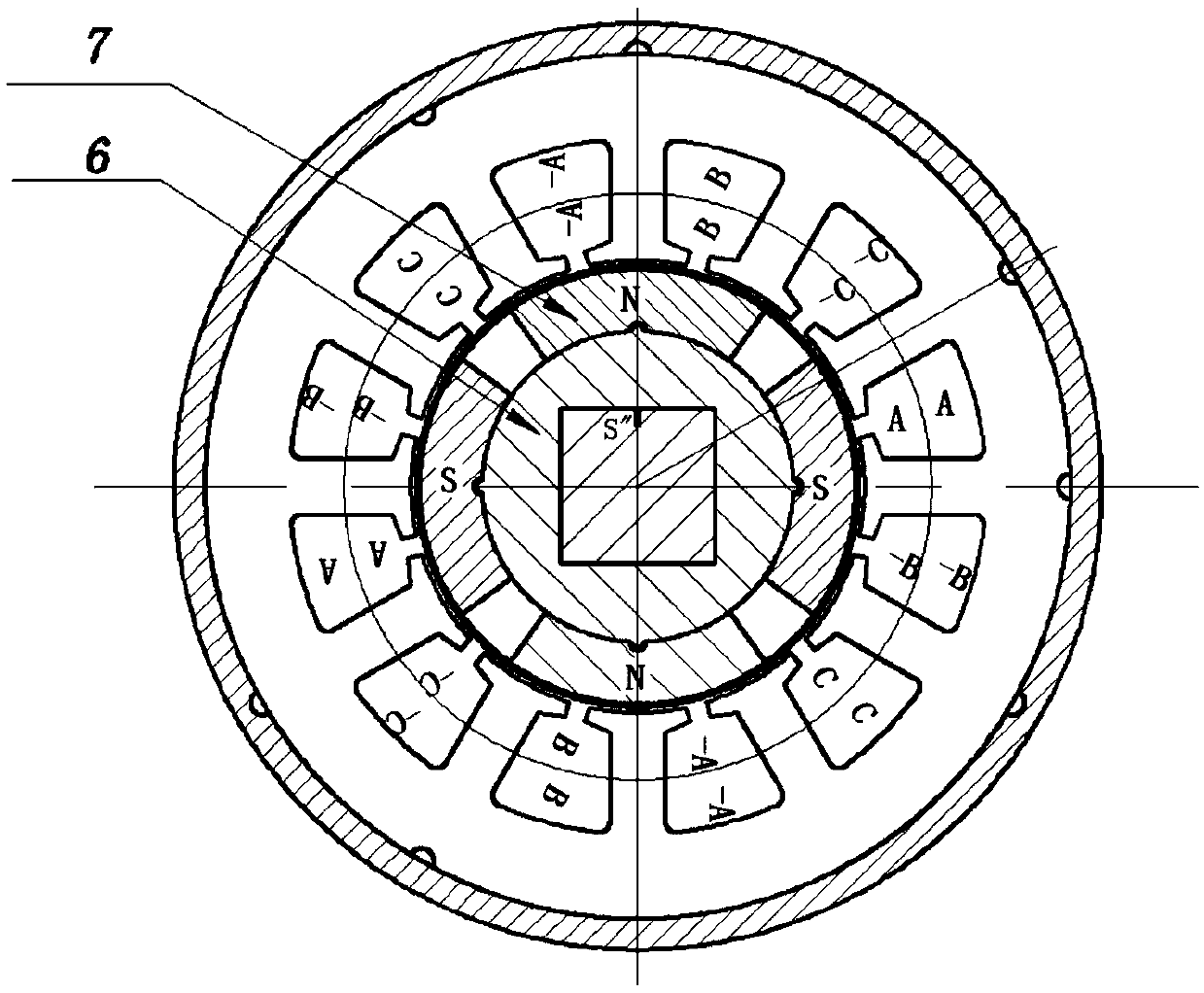

[0028] In this embodiment, a brushless DC motor with 4 poles and 12 slots is taken as an example to describe in detail, and the driving control mode adopts a common three-phase full-wave six-state working mode.

[0029] In order to obtain the largest possible motor torque output, the back EMF of the same phase and the current are in the same direction. Therefore, under the guidance of this theory, for a certain phase of the motor such as A phase, 30° after the A opposite EMF zero crossing point The electrical angle moment should be the moment when the upper jump edge of the phase A Hall circuit output HA appears. For this example, the three-phase windings of the motor are Figure 4 The distribution shown is in the form of double-layer windings with full pole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com