Construction Method of Welding and Positioning Device for Large Ladle Hanging Shaft

A welding positioning and construction method technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of wasting materials, labor and time, etc., and achieve the effect of simplifying the process, simple operation and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

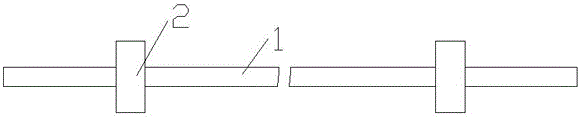

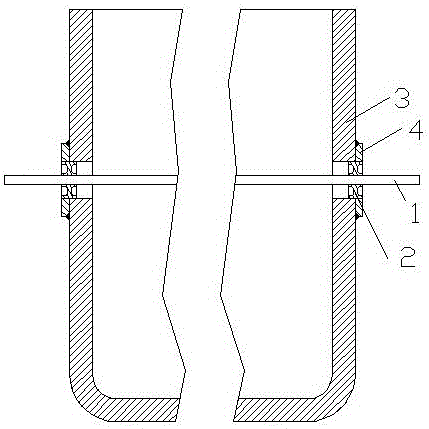

[0014] Such as Figure 1~2 As shown, the solution adopted by the present invention to solve the technical problem is that the solution adopted by the present invention is a welding positioning device for a large ladle hanging shaft, which includes a long positioning shaft 1 and two positioning circles of the same size Disk 2, the cylindricity error of the peripheral side of the long positioning shaft 1 is not greater than 0.05mm, the positioning disc 2 is coaxial with the long positioning shaft 1, and the coaxiality error between the positioning disc 2 and the long positioning shaft 1 is not greater than 0.03mm, two positioning discs 2 are relatively parallel and detachably sleeved on the long positioning shaft 1 .

[0015] In this embodiment, in order to prevent the long positioning shaft 1 from rusting and improve the service life, the long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com