Automatic leveling laser transmitter fixture

A laser transmitter and flattening technology, which is applied in light guides, optics, instruments, etc., can solve problems such as difficult coupling, uneven bonding, and large changes in optical power, and achieve a large operating space, small footprint, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

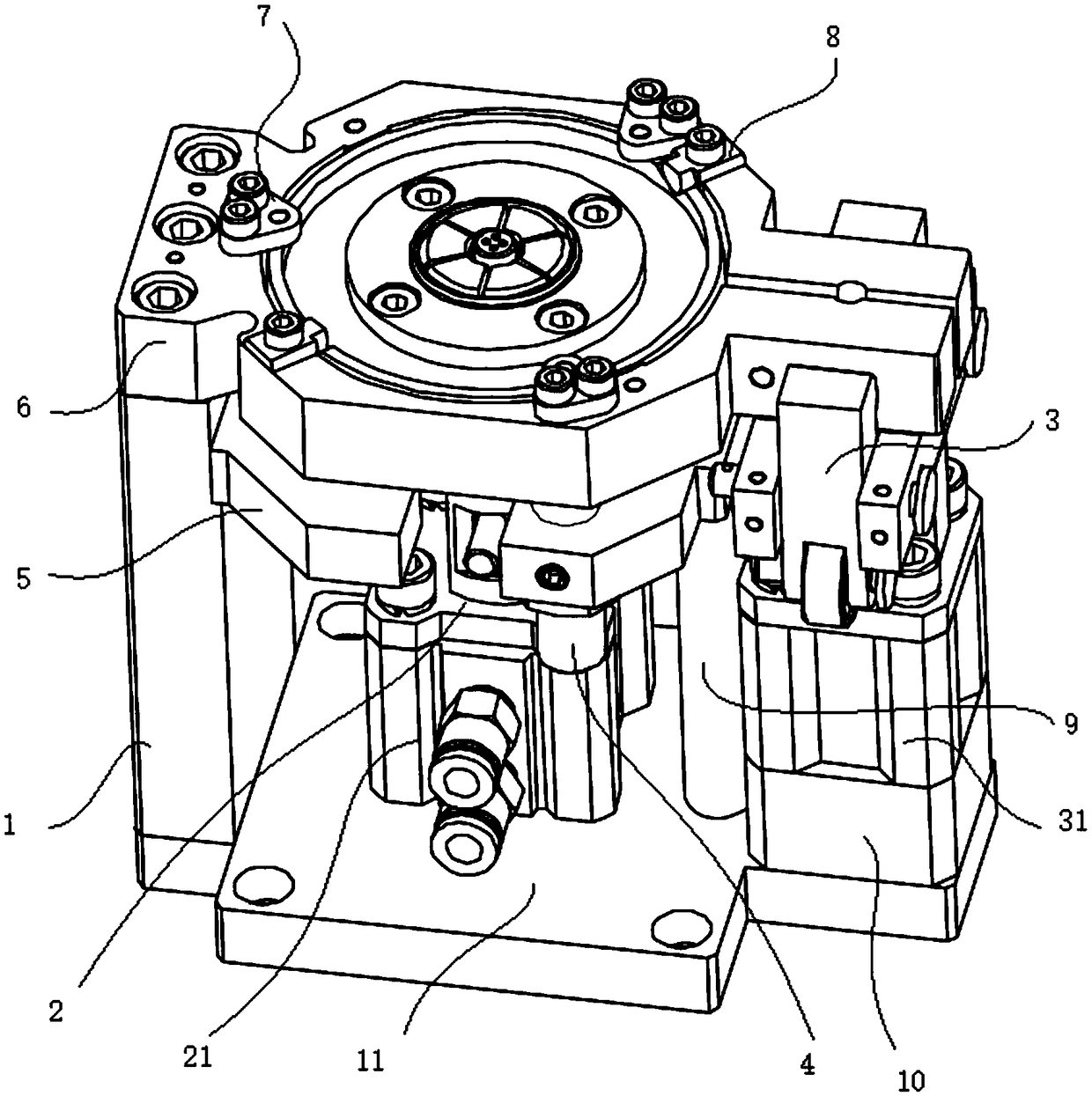

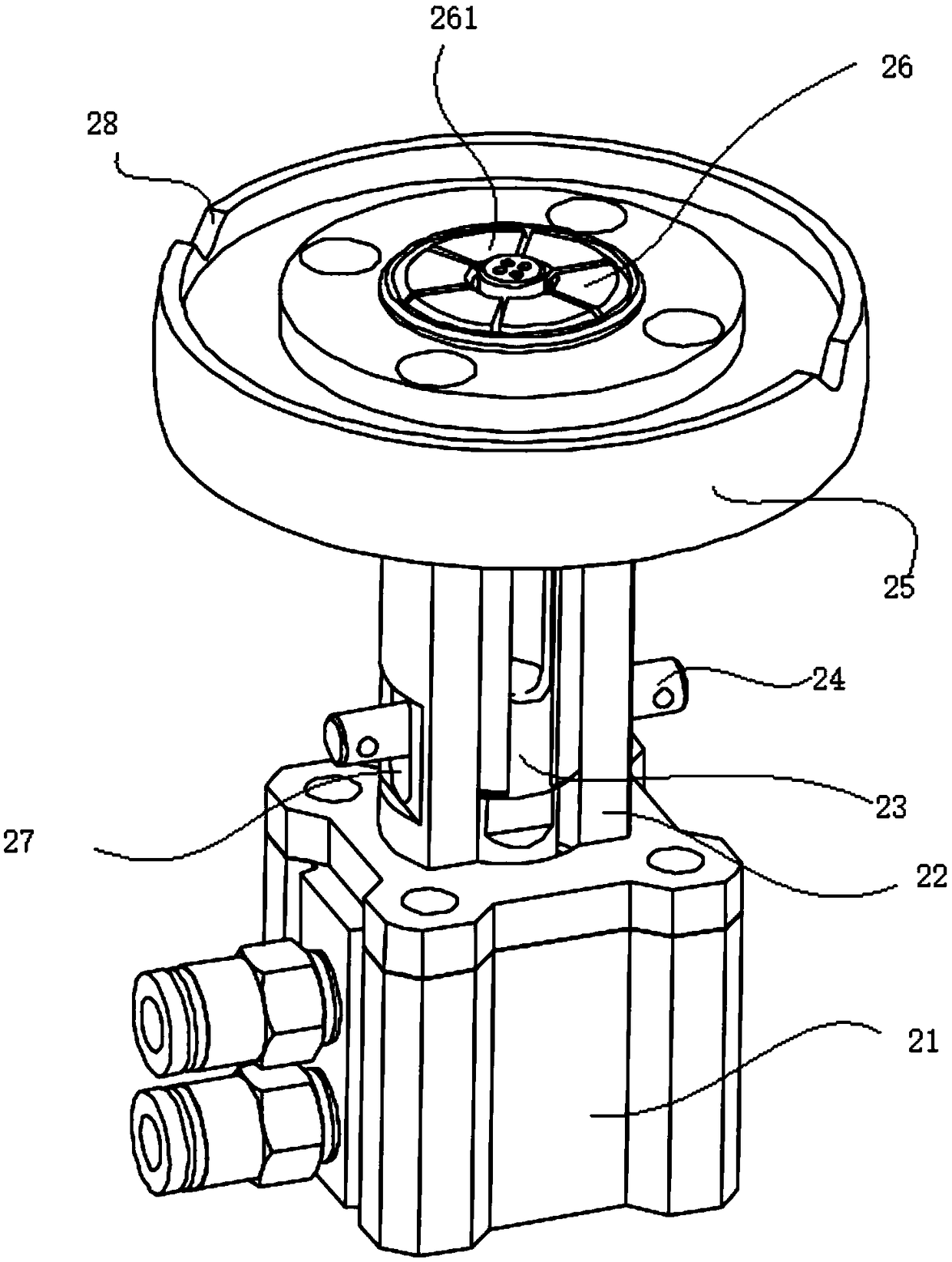

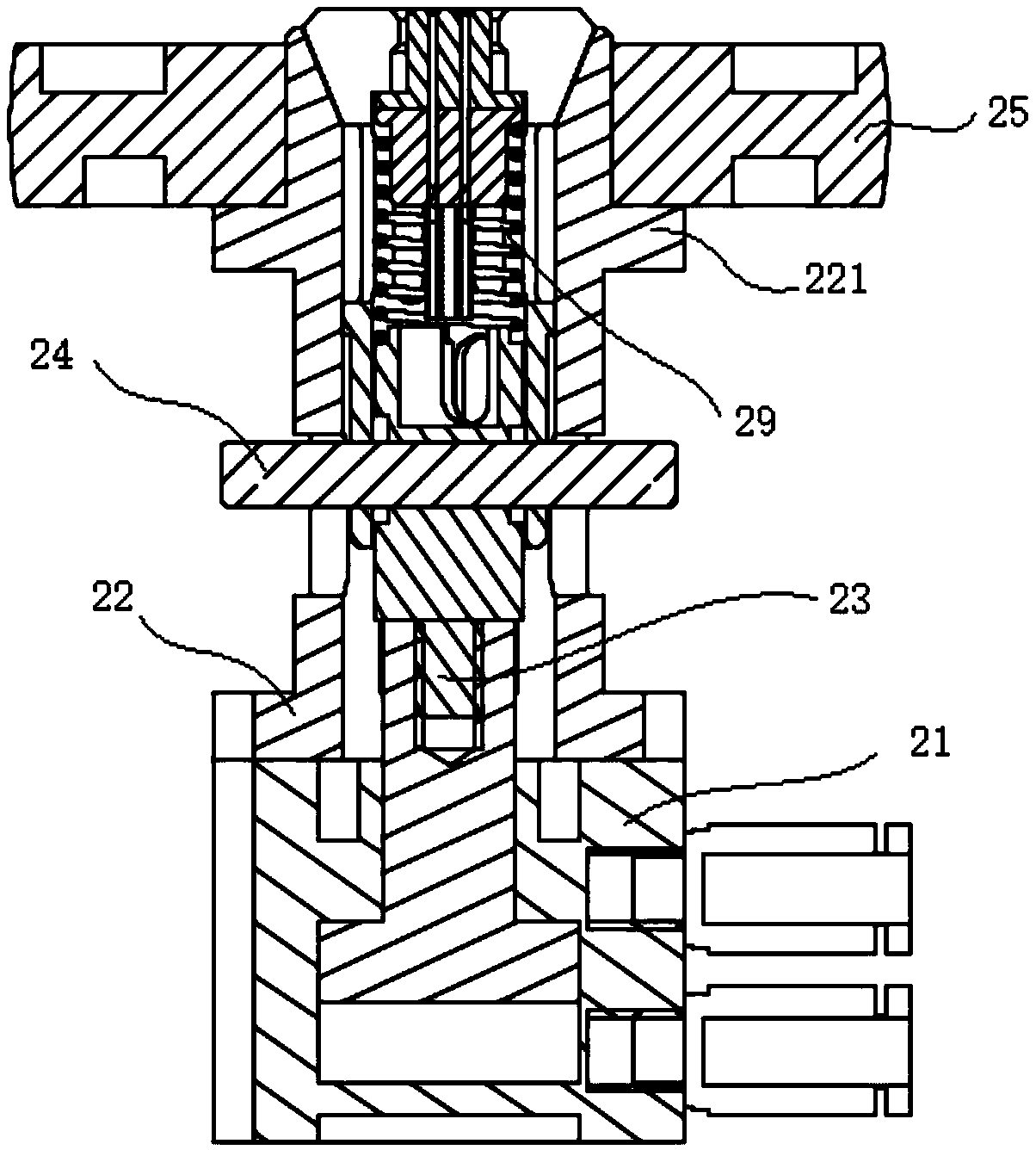

[0030] Such as Figure 1-4As shown, an automatic flattening laser transmitter fixture includes a frame, and a locking and positioning assembly arranged on the frame, a floating assembly 2, an angle fixing assembly 3, and a level adjustment assembly; the locking and positioning assembly Set on the upper part of the frame, the floating assembly 2 includes a movable disk 25 with a hole in the middle, a locking sleeve 22 that passes through the hole in the middle of the movable disk 25 and is tightly connected with the movable disk 25, and is arranged on the locking sleeve. Clamps in 22; the locking and positioning device can lock and position the floating ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com