Slag discharge structure of secondary combustor

A technology of secondary combustion chamber and melting chamber, which is applied in the field of slagging structure of the secondary combustion chamber, which can solve the problems of inconvenient slagging and easy blockage of the secondary combustion chamber, and achieve the effects of complete combustion, accelerated flow and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a further detailed description through specific implementations:

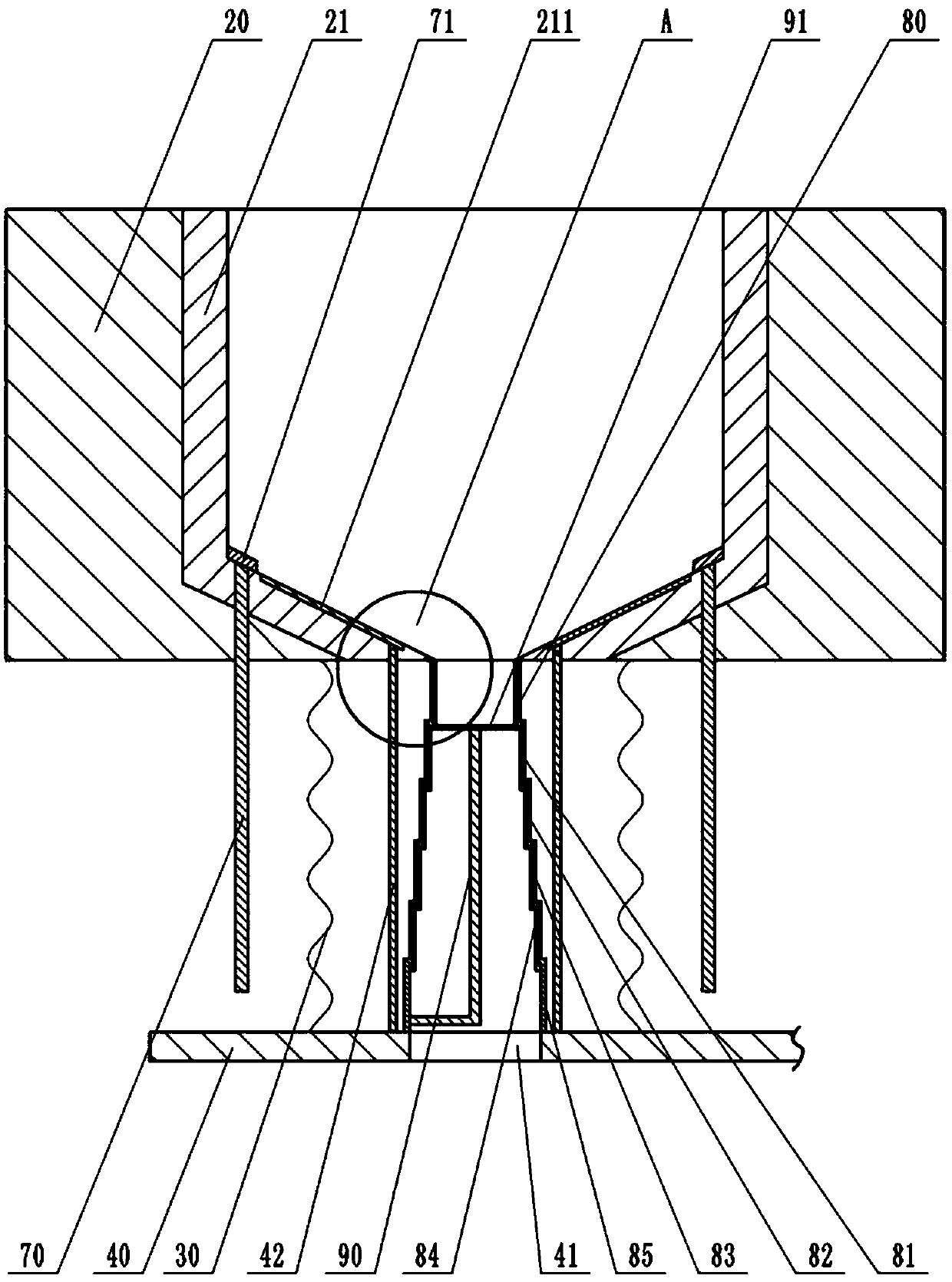

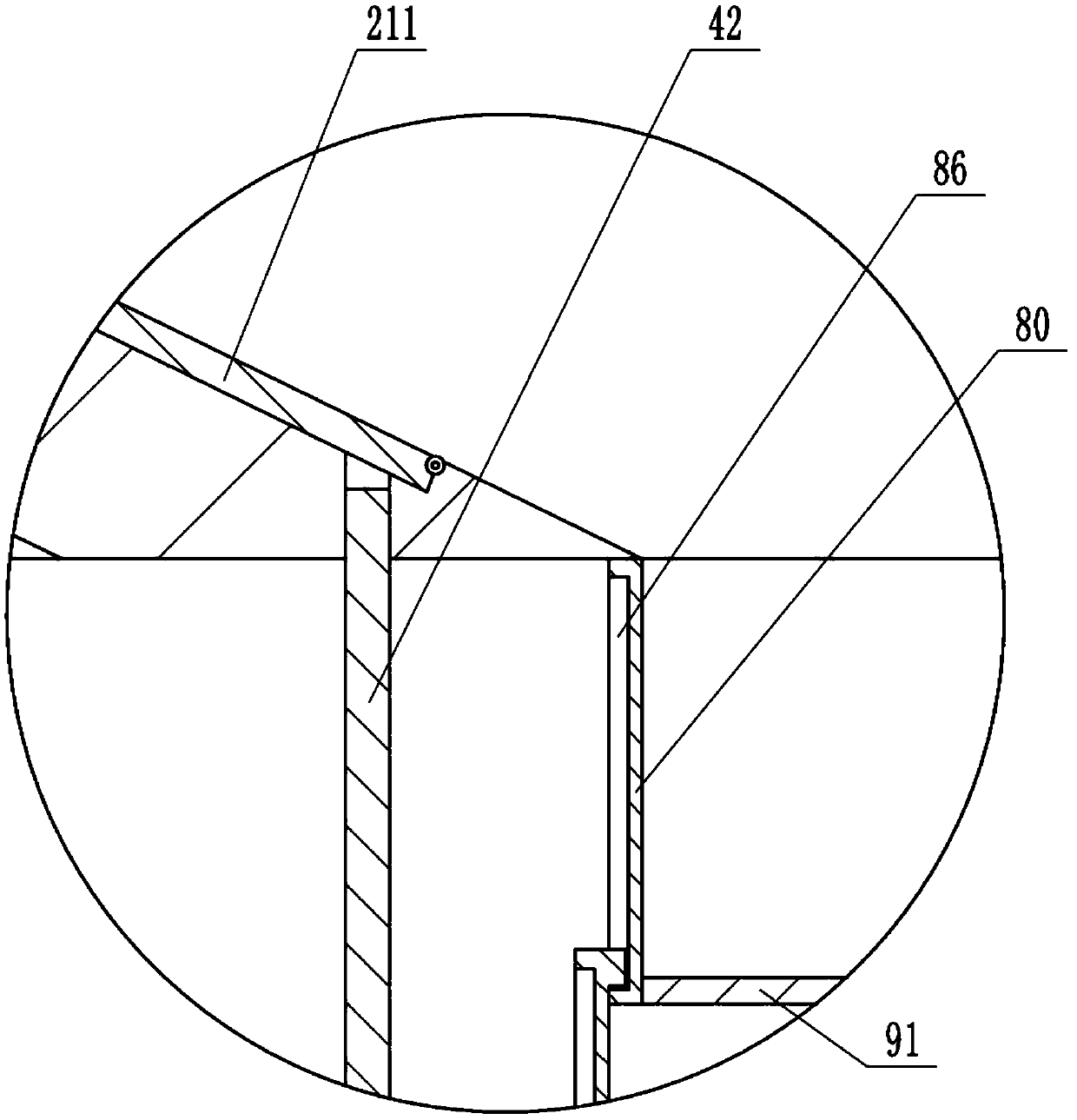

[0022] The reference signs in the drawings of the specification include: second combustion chamber 10, melting unit 20, melting chamber 21, turning plate 211, return spring 212, bellows 30, bottom plate 40, through hole 41, top rod 42, motor 50, rotation Column 60, curved groove 61, extension rod 62, push rod 70, annular scraper 71, fixed tube 80, first annular tube 81, second annular tube 82, third annular tube 83, fourth annular tube 84, The fifth annular cylinder 85, the limiting groove 86, the connecting rod 90, and the push plate 91.

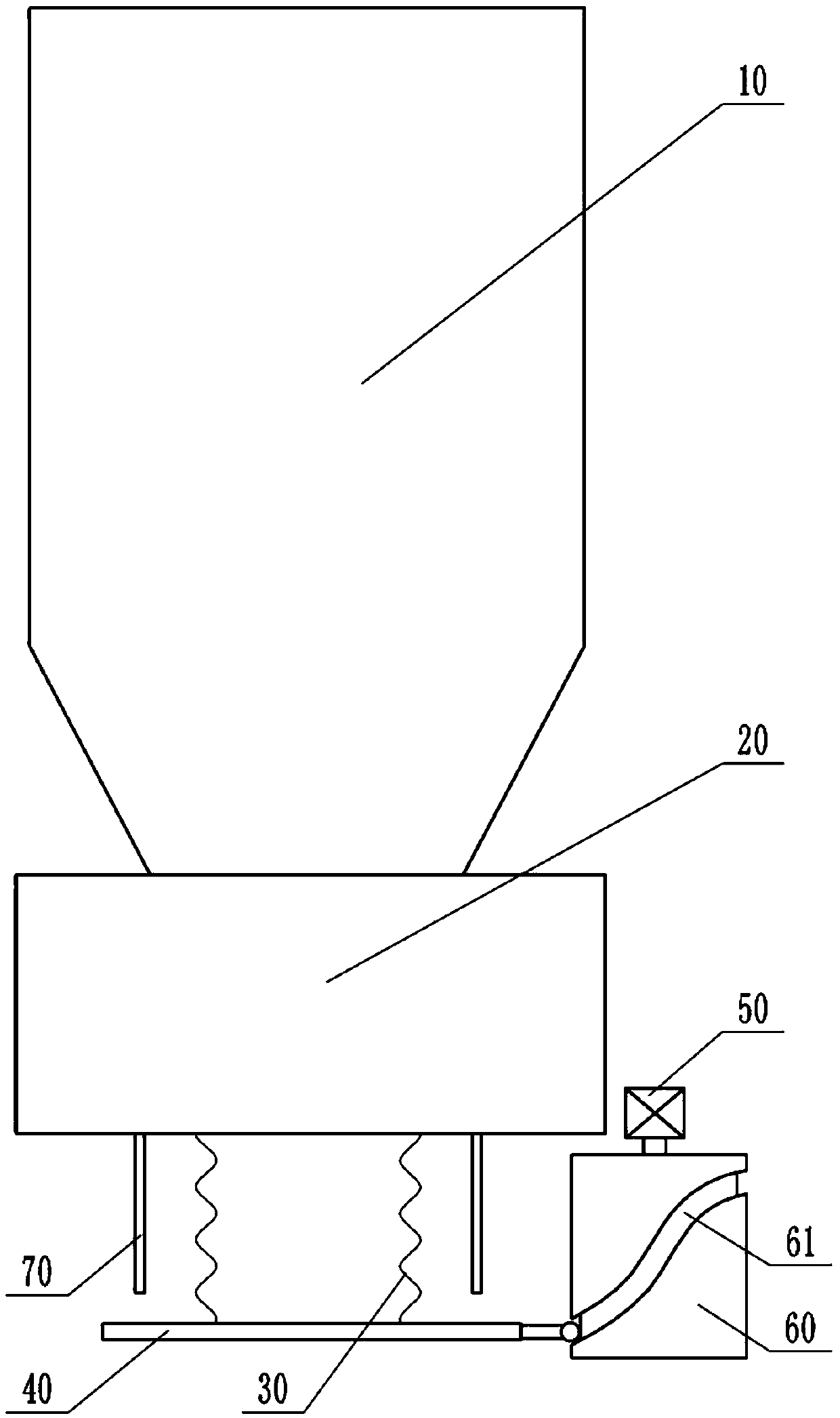

[0023] The embodiment is basically as attached figure 1 As shown: the slag discharge structure of the second combustion chamber includes a melting unit 20 which is arranged at the lower end of the second combustion chamber 10. The melting unit 20 includes a heat preservation base and a melting chamber 21 located in the heat preservation base, and a combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com