Rotary valve pump

A technology of rotary valves and pump sleeves, which is applied to pump components, variable capacity pump components, and components of pumping devices for elastic fluids, etc., and can solve the problem of high dimensional accuracy, complex structure, and poor sealing effect of the shrink sleeve process And other problems, to achieve a wide range of applications, easy to clean, save the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

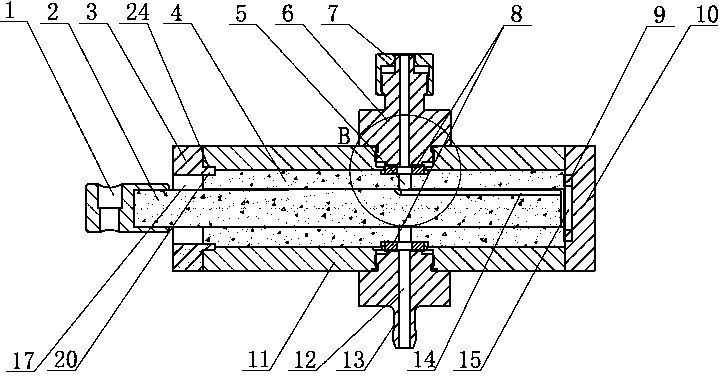

[0031] The specific embodiments of the present invention will be described below in conjunction with the drawings.

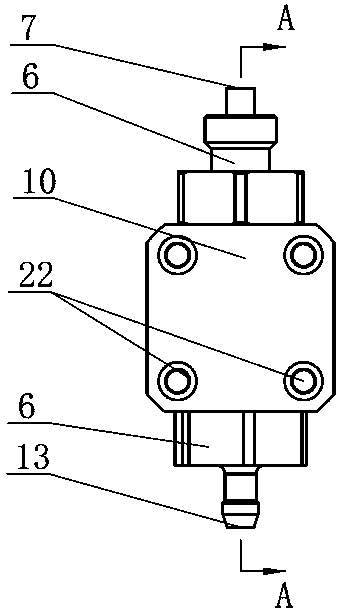

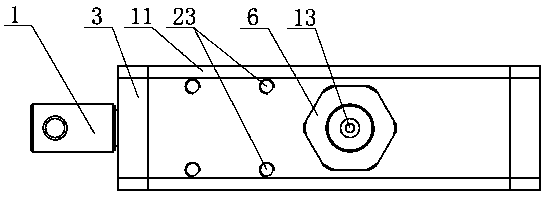

[0032] Such as figure 2 As shown, the housing 11 of the present invention is a rectangular parallelepiped with a circular pump sleeve hole in the center, and the material is non-ceramic metal or plastic. The upper and lower surfaces of the housing 11 are penetrated with first step holes, and in the first step The holes of the holes are provided with threads that engage with the screw part of the inlet and outlet nozzle bolts 6. The heads of the inlet and outlet nozzle bolts 6 on the upper and lower surfaces are respectively connected to the outlet nozzle 7 and the inlet nozzle 13, and the inside of the inlet and outlet nozzle bolts 6 A liquid inlet and outlet channel 12 is opened, which communicates with the liquid outlet nozzle 7 and the liquid inlet nozzle 13; the liquid inlet and outlet nozzle bolts 6 are locked in the first step holes on the upper and lower sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com