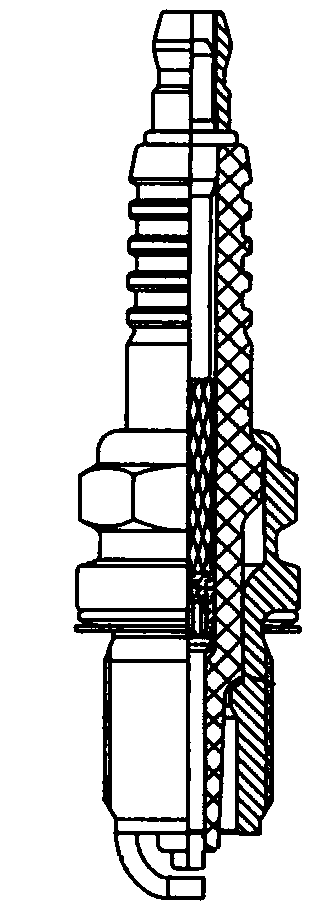

Double-discharge plasma igniter with hollow ventilation anodes

A plasma and discharge mode technology, applied in the directions of plasma, engine ignition, electrical components, etc., can solve the problems of poor ignition reliability, low ignition energy utilization, small ignition energy, etc., and achieve improved combustion, high working pressure, and stability. effect of ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

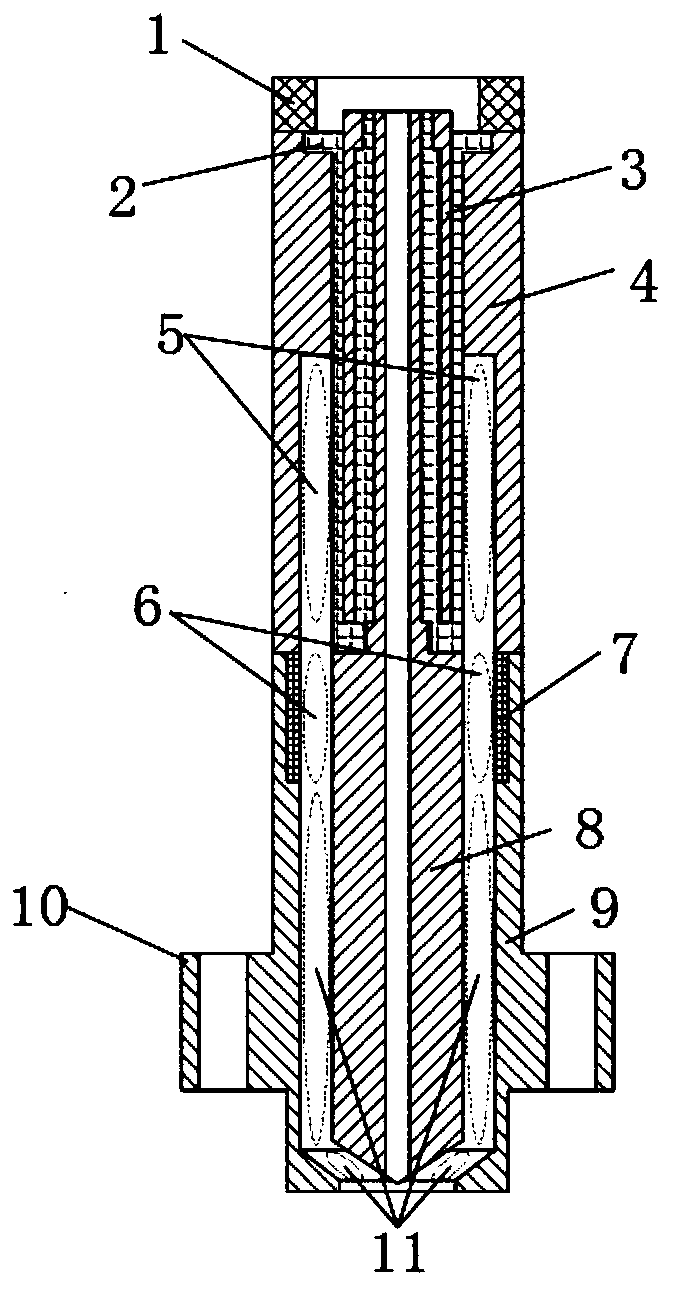

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: taking this as an example to further describe and illustrate the present application.

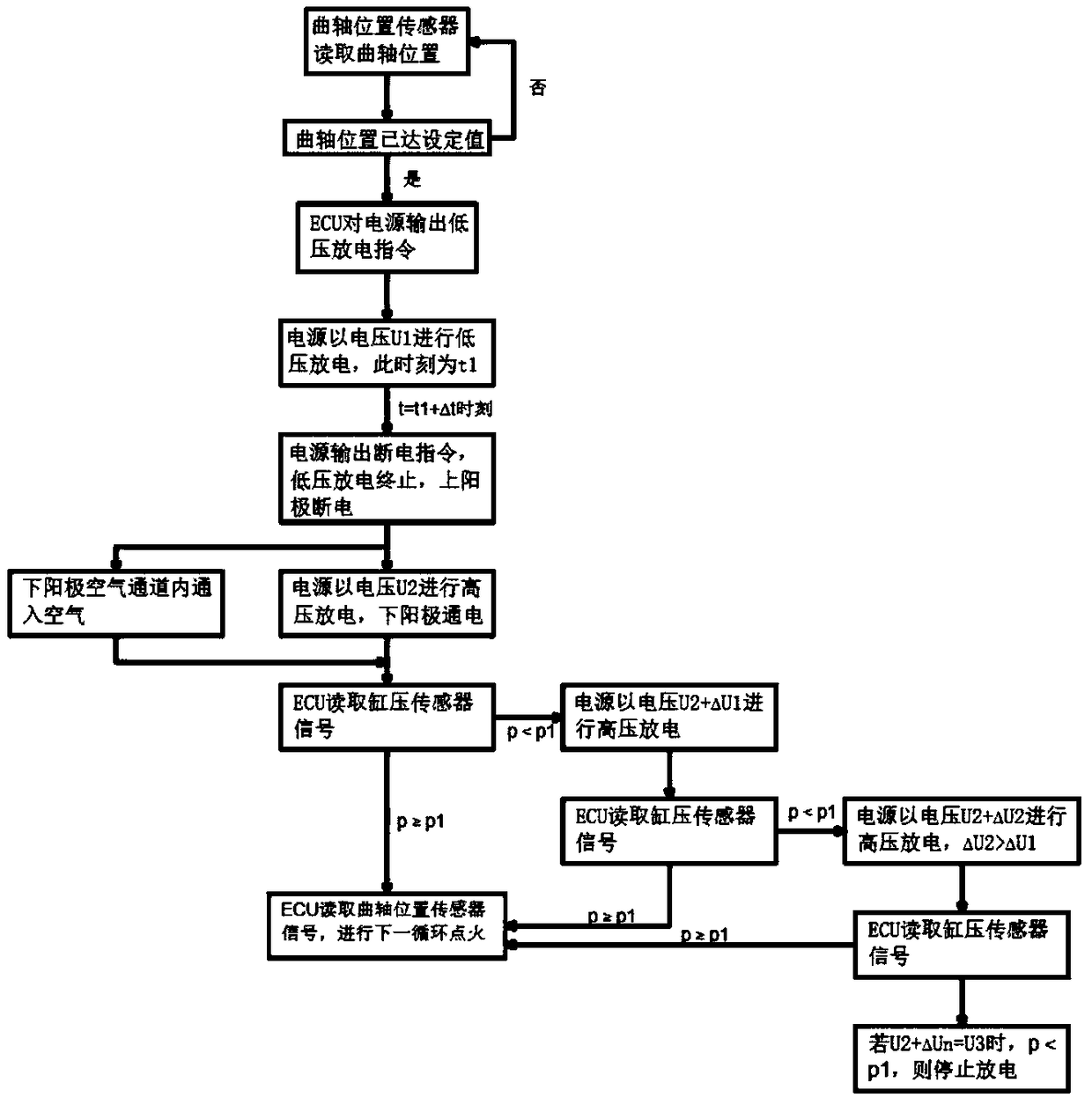

[0020] Such as Figure 2-4 As shown, this embodiment provides a double-discharge mode plasma igniter with a hollow vented anode, including an upper anode, a lower anode, an upper ground electrode, a lower ground electrode, an anode insulating sleeve, a ground electrode insulating sleeve, and fixing bolts; The upper anode is located at the center of the igniter, and is installed and fixed in the anode insulating sleeve; the lower anode has a hollow structure and is installed in the installation hole in the anode insulating sleeve; the anode insulating sleeve is used to fix the upper anode and the lower anode, and The insulation between the two is realized; the anode insulating sleeve is installed on the upper ground electrode, and the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com