Auxiliary ammonia uniformity testing equipment and testing method thereof

An auxiliary detection and uniformity technology, which is applied in the direction of mechanical equipment, electric control of exhaust treatment devices, diagnostic devices of exhaust treatment devices, etc., can solve problems such as not enough to explain the real situation, and achieve low cost, simple operation, The effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

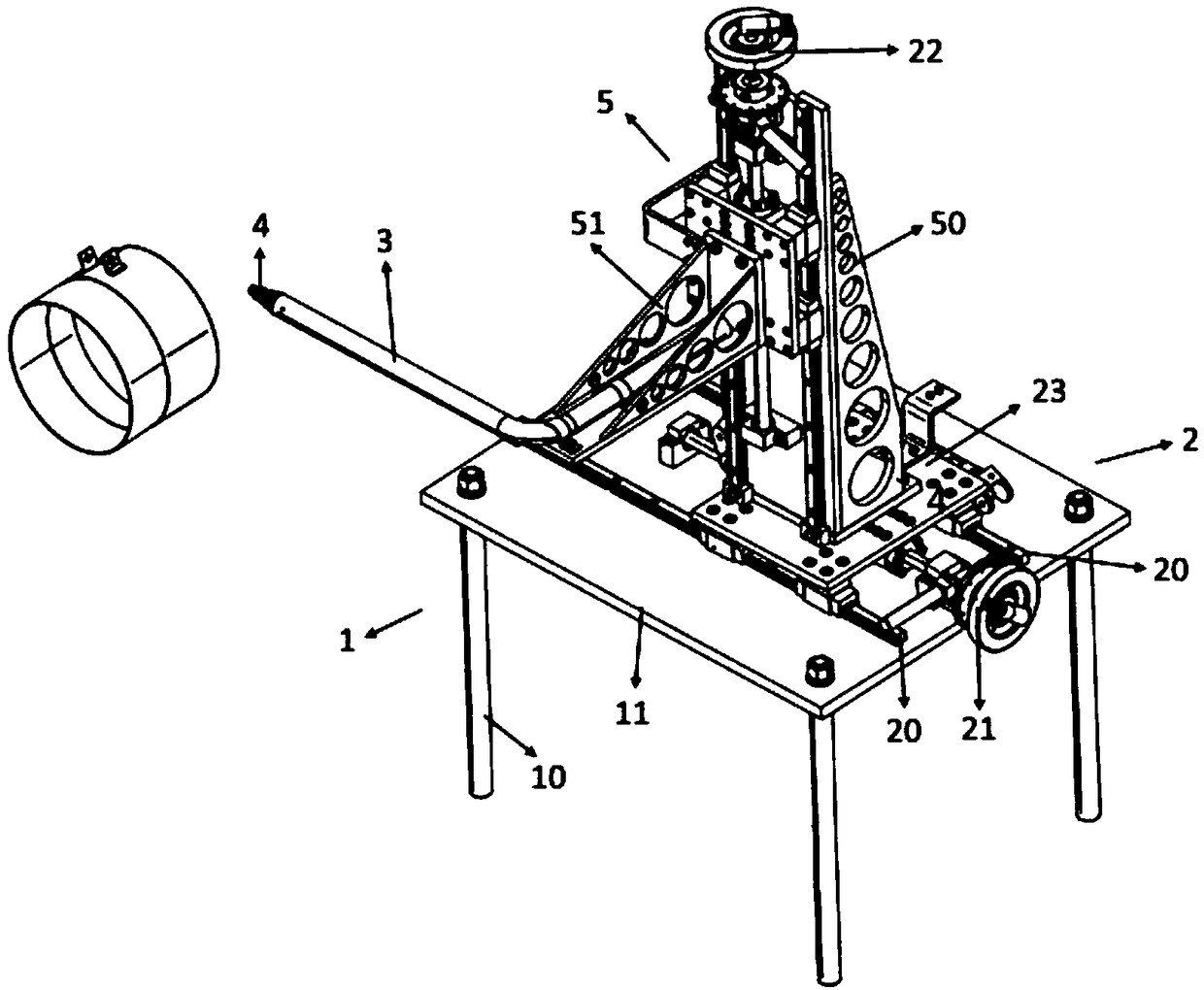

[0025] like figure 1 As shown, this embodiment includes: a mobile platform 2 arranged on a support platform 1 and a sensor 4 connected to the mobile platform 2 through a sensor support tube 3 .

[0026] The support platform 1 includes: four platform support legs 10 and a platform panel 11 connected to the top thereof.

[0027] The mobile platform 2 includes: two parallel metal rails 20 fixedly arranged on the platform panel, a horizontal slide bar 21, a vertical slide bar 22 with a sensor mobile bracket 5 and a metal plate 23, wherein: the horizontal slide bar 21 is arranged on two metal rails 20, the vertical slide bar 22 is perpendicular to the horizontal slide bar 21 and a metal plate 23 is arranged between the two.

[0028] The sensor moving bracket 5 is arranged on the outer periphery of the vertical slide bar 22 .

[0029] The mobile bracket 5 includes: a pillar 50 vertically arranged on the outer periphery of the slide bar and a bracket 51 horizontally supporting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com