Manufacturing process of green plum wine

A production process and technology of green plum wine, which is applied in the field of fruit wine brewing, can solve the problems of affecting the aroma of green plum wine and reducing the mellowness of wine aroma in clear plum wine, so as to achieve the effect of refreshing taste and increasing wine aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

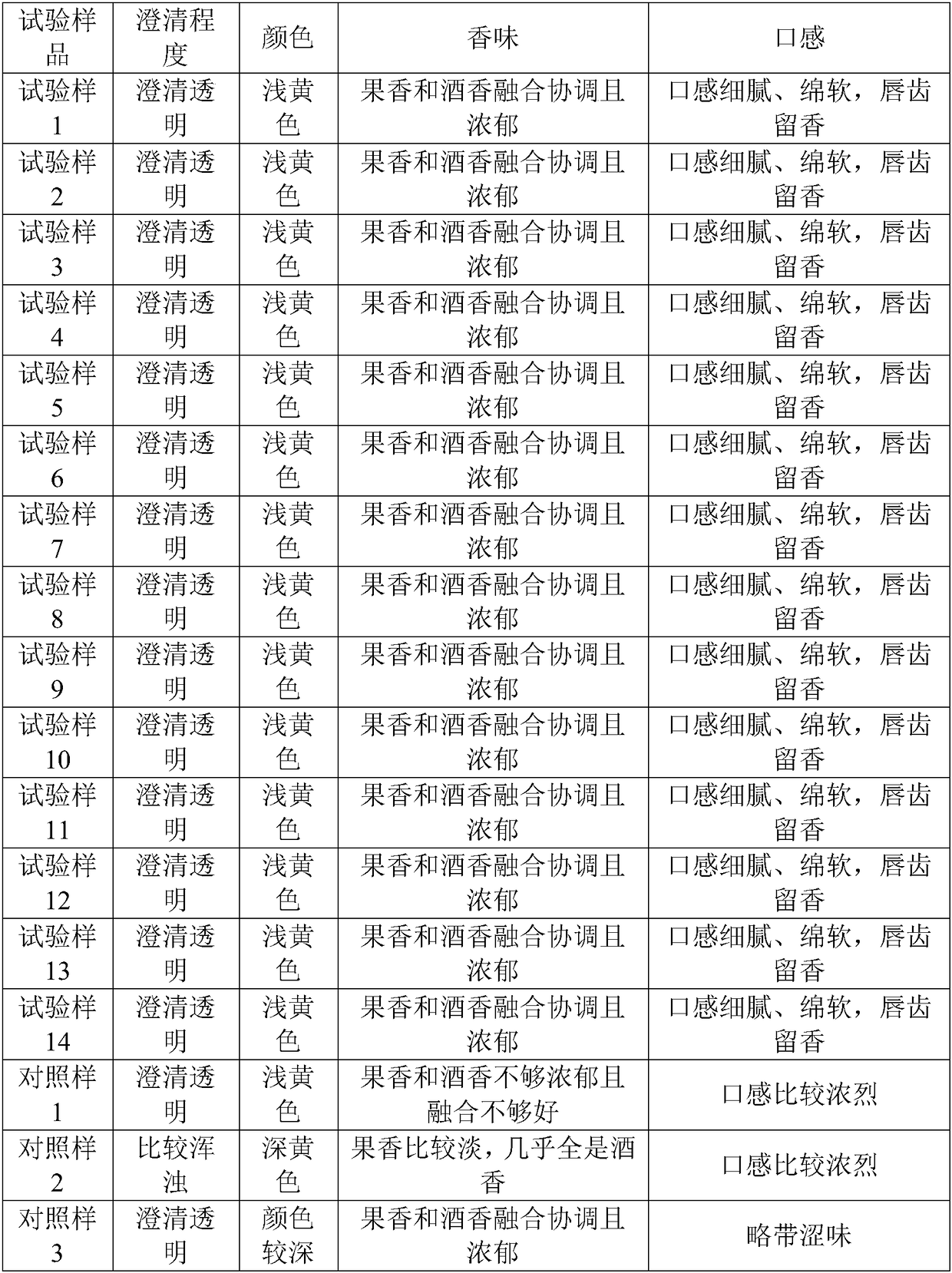

Embodiment 1

[0067] Embodiment 1: a kind of manufacturing process of green plum wine, comprises the following steps and prepares and obtains:

[0068] Step 1, screening and cleaning greengage: choose greengage with uniform size, no insect spots, water spots, pinch marks, and bruises as raw materials, and clean them with pure water;

[0069] Step 2, removing astringency and drying in the shade: soak the greengage cleaned in Step 1 in a saline solution with a mass concentration of 15% for 15 minutes, remove and dry in the shade;

[0070] Step 3, pitting and pretreatment: remove the pitting of the greengage after drying in the shade in step 2, and evenly pierce the needle holes (the diameter of the needle is 1 mm) on the inside and outside of the greengage, and then sew up the greengage after the pinhole with cotton thread form the original overall shape;

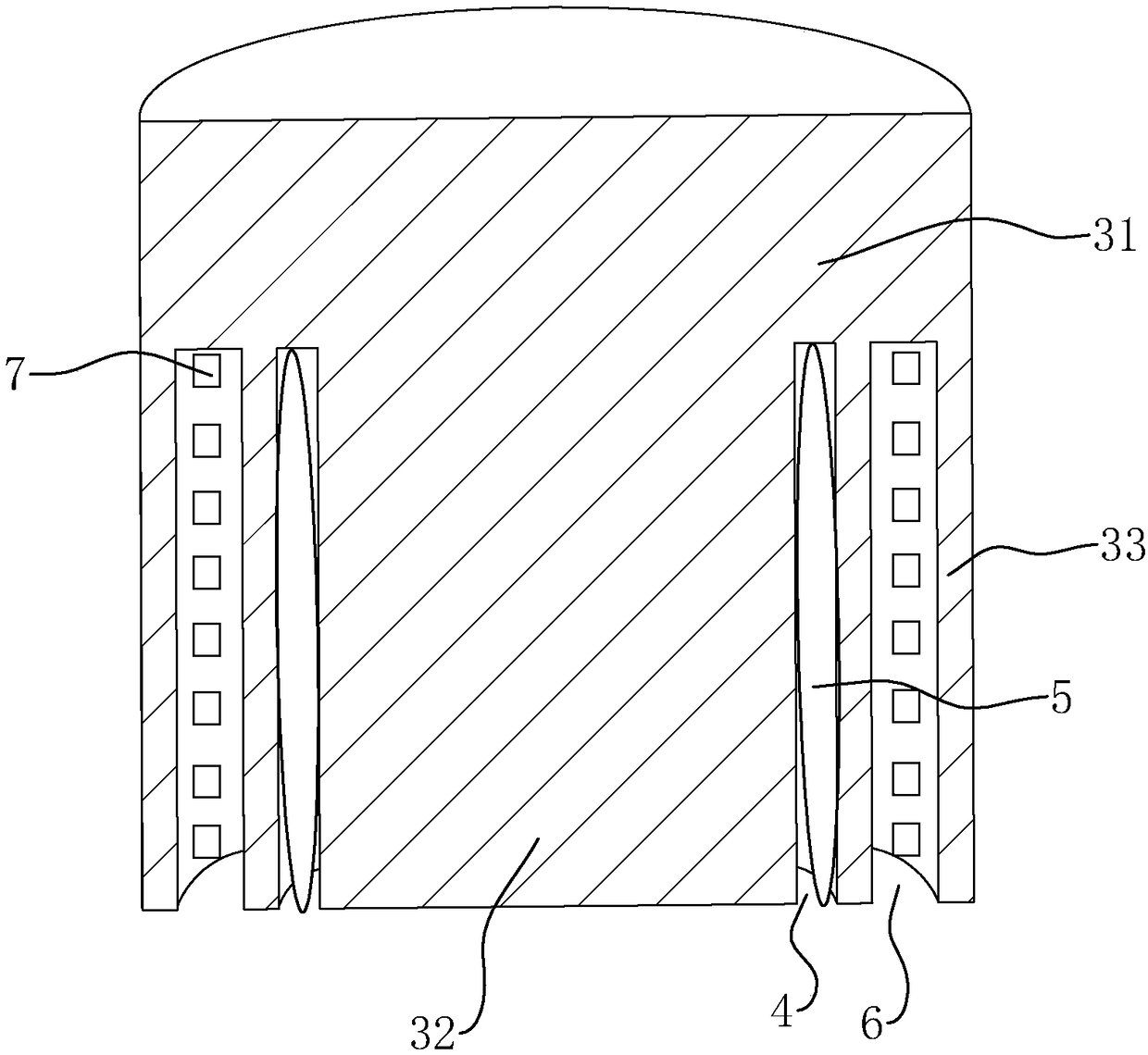

[0071] Step 4, add materials: Add a layer of pine needles, a layer of coconut shell, and a layer of greengage obtained in step 3 to the ...

Embodiment 2

[0081] Embodiment 2: a kind of manufacture craft of plum wine, the difference with embodiment 1 is,

[0082] In step 2, the mass concentration of the saline solution is 12%, and the soaking time is 30 minutes;

[0083] In step 3, the diameter of the needle piercing the needle hole is 0.5mm;

[0084] In step 4, in the pine needle layer, the coconut shell layer and the green plum layer, the ratio of parts by weight of pine needles, coconut shell and green plum is 1.5:1:2.2; then add rock sugar, and the ratio of rock sugar to green plum is 1:4;

[0085] In step 5, the alcoholic degree of the added wine is 50 degrees;

[0086] In step 7, the temperature of the cellar storage is 19° C., the relative humidity is 70%, and it is stored for 90 days, and the wine jar is gently shaken every 30 days.

Embodiment 3

[0087] Embodiment 3: a kind of manufacture craft of plum wine, the difference with embodiment 1 is,

[0088] In step 2, the mass concentration of the saline solution is 13%, and the soaking time is 25 minutes;

[0089] In step 3, the diameter of the needle piercing the needle hole is 0.8mm;

[0090] In step 4, in the pine needle layer, the coconut shell layer, and the green plum layer, the ratio by weight of pine needles, coconut shell, and green plum is 1.4:1:2.5; then add rock sugar, and the ratio by weight of rock sugar to green plum is 1:3;

[0091] In step 5, the alcoholic degree of the added wine is 45 degrees;

[0092] In step seven, the temperature of cellar storage is 22° C., the relative humidity is 65%, and the wine jar is kept for 88 days, and the wine jar is shaken every 30 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com