Pressure-sensitive adhesive product for battery packaging and preparation method thereof

A technology for pressure-sensitive adhesives and packaging. It is applied in the field of pressure-sensitive adhesives. It can solve the problems of aging resistance and heat and humidity resistance of adhesive threads and battery residues, and achieve strong initial adhesion, strong bonding performance, and high wettability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

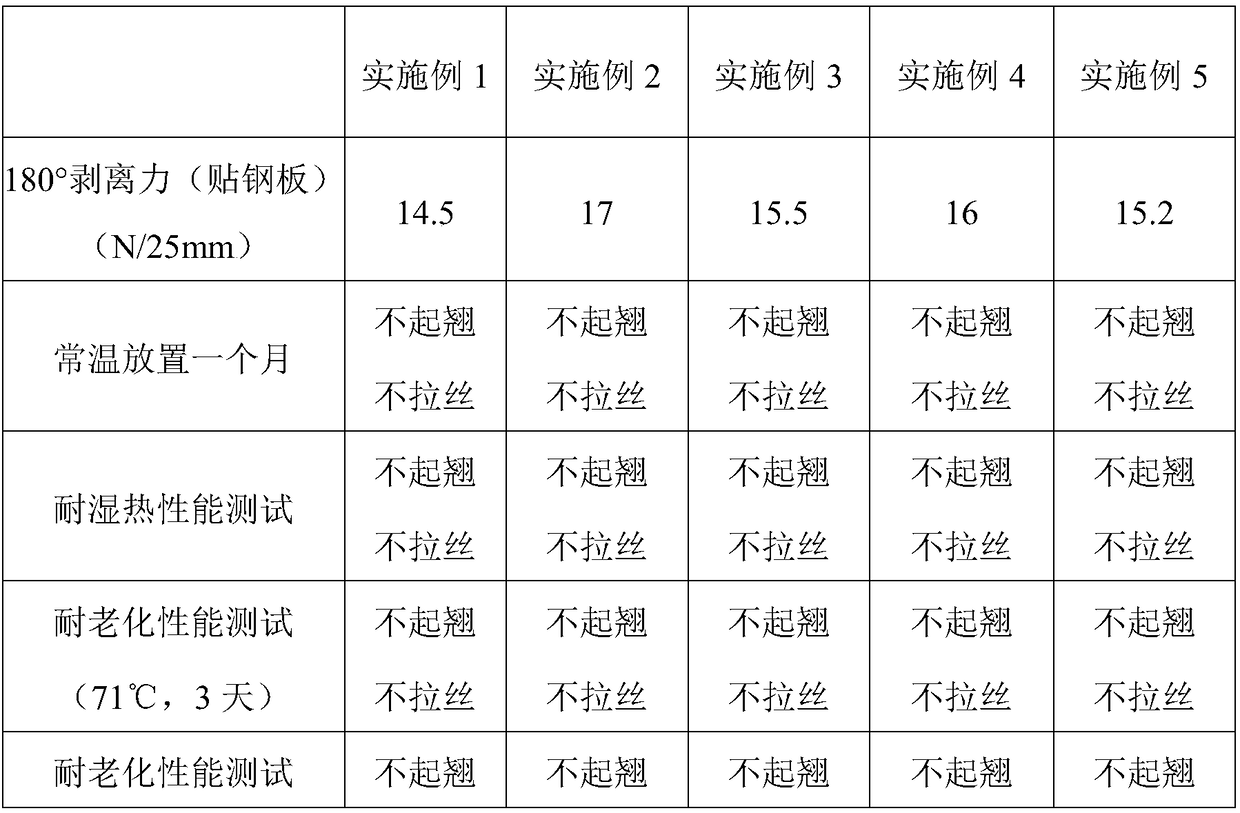

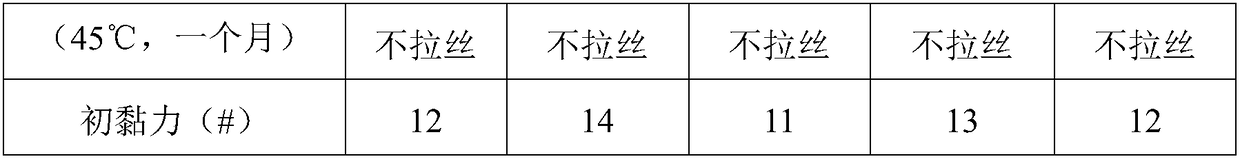

Examples

Embodiment 1

[0028] (1) Add all 17g of SBS rubber into 50g of toluene and 15g of ethyl acetate until completely dissolved, and the reaction temperature is 65-85°C to prepare a mixed solvent;

[0029] (2) After mixing 5g of methyl acrylate, 1g of ethyl acrylate, 10g of butyl acrylate, 2g of hydroxyethyl acrylate, and 0.035g of dibenzoyl peroxide, add it dropwise to the mixed solvent for 1.5h , holding time is 3h;

[0030] (3) Add 0.17g of hydroquinone to terminate the reaction, cool down to 50°C, and discharge;

[0031] (4) Weigh part of the glue solution discharged in step (3) and add hexamethylene diisocyanate in an amount of 0.1% of the weight of the glue solution, fully stir, and coat the obtained glue on a release film at 105°C Cured for 5 minutes, the thickness after curing was controlled at 10 μm, and then transferred to a 50 μm aluminized PET film for testing.

Embodiment 2

[0033] (1) Add 23g of SBS rubber into 50g of toluene and 15g of ethyl acetate until completely dissolved, and the reaction temperature is 65-85°C to prepare a mixed solvent;

[0034] (2) After mixing 2g of methyl acrylate, 0.5g of isobutyl methacrylate, 6g of butyl acrylate, 2g of lauryl methacrylate, 1.5g of acrylic acid, and 0.105g of dibenzoyl peroxide, add dropwise to the mixing In the solvent, the dropping time is 2h, and the holding time is 4h;

[0035] (3) Add 0.23 g of hydroquinone to terminate the reaction and cool down to 50° C., then discharge;

[0036] (4) Take by weighing part of the glue solution discharged in step (3) and add triglycidyl isocyanurate, the consumption is 0.6% of the glue solution weight, fully stir, the gained glue is coated on the release film, 105 ℃ Cured for 5 minutes, the thickness after curing was controlled at 10 μm, and then transferred to a 50 μm aluminized PET film for testing.

Embodiment 3

[0038] (1) Add 28g of SBS rubber into 65g of toluene until completely dissolved, and the reaction temperature is 65-85°C to prepare a mixed solvent;

[0039] (2) After mixing 1g of methyl acrylate, 3g of butyl acrylate, 3g of hydroxypropyl acrylate, and 0.175g of dibenzoyl peroxide, add it dropwise to the mixed solvent. The dropping time is 2.5h, and the holding time is 5h. ;

[0040] (3) Add 0.28 g of hydroquinone to terminate the reaction, cool down to 50° C., and discharge;

[0041] (4) take by weighing the part glue solution of discharging in step (3) and add m-xylylenediamine type epoxy resin, consumption is 1% of glue solution weight, fully stirs, gained glue is coated on the release film, Cured at 105°C for 5 minutes, the thickness after curing was controlled at 10 μm, and then transferred to a 50 μm aluminized PET film for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com