A kind of functionalized graphene/polymethacrylimide composite wave absorbing material and preparation method thereof

A technology of polymethacrylimide and composite absorbing materials, which is applied in the field of absorbing materials, can solve the problems of inflexible structure application, high density of absorbing materials, poor impedance matching, etc., and achieve cost reduction, low cost, Effect of Optimizing Electromagnetic Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

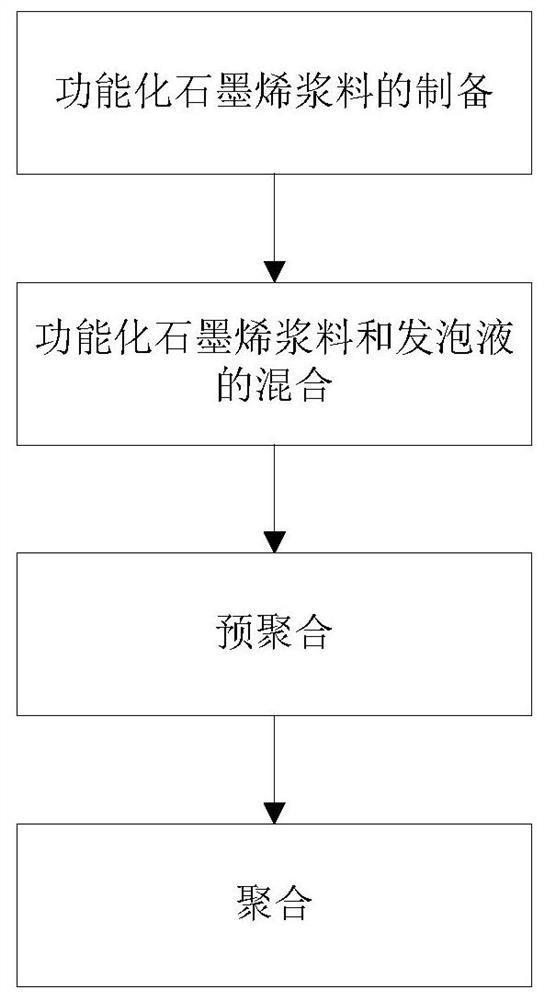

[0044] The present invention provides a kind of preparation method of functionalized graphene / polymethacrylimide composite absorbing material in the first aspect, such as figure 1 As shown, the method includes the following steps:

[0045] (1) Preparation of functionalized graphene slurry

[0046] Mix graphene, resin, modifier, coupling agent, dispersant, wetting agent and organic solvent uniformly to obtain functionalized graphene slurry; wherein, the modifier is selected from any of KH550, KH560, and KH570 One or more, its quality is 1%~5% of graphene quality; Described coupling agent is selected from any one or more in TMC-101, TMC-102, TMC-201, and its quality is graphene 0.5% to 2% of the mass.

[0047]The surface of graphene is inert, has high chemical stability and is easy to aggregate, making it difficult for graphene to disperse uniformly in solvents (such as water and organic solvents). Adding graphene into the PMI (Chinese name: polymethacrylimide) matrix also ha...

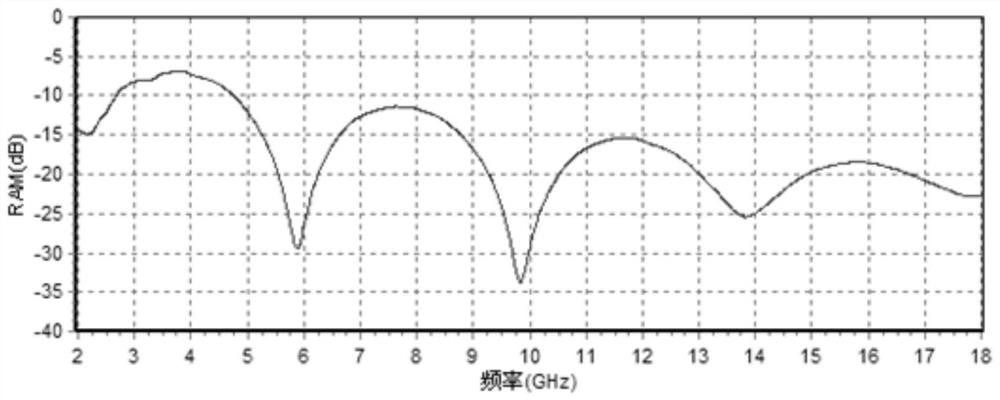

Embodiment 1

[0069] (1) Preparation of functionalized graphene slurry

[0070] Weigh 90 parts by mass of graphene, 1.2 parts by mass of modifier KH550, 210 parts by mass of two-component epoxy resin, 120 parts by mass of absolute ethanol, 1.3 parts by mass of dispersant BYK-W903, and 1.2 parts by mass of wetting agent BYK-103 Parts, 0.8 parts by mass of coupling agent TMC-101, after high-speed dispersion treatment by a homogenizer, obtain a uniformly mixed functionalized graphene slurry.

[0071] (2) Mixing of functionalized graphene slurry and foaming liquid

[0072] Weigh 80 mass parts of methacrylic acid, 80 mass parts of methacrylonitrile, 0.7 mass parts of azobisisobutyronitrile, a mixture of n-butanol and tert-butanol (the mass ratio of the two is 1:1) 8 mass parts 3 parts by mass of acrylamide and 3 parts by mass of acrylamide are uniformly mixed, then the functionalized graphene liquid slurry prepared in step (1) is added, the system is uniformly dispersed by high-speed shear stir...

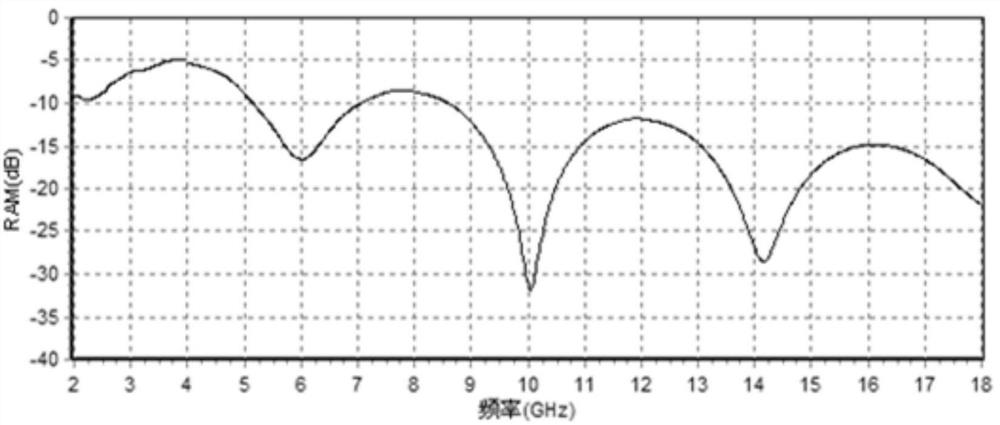

Embodiment 2

[0078] (1) Preparation of functionalized graphene slurry

[0079] Weigh 120 parts by mass of graphene, 1.2 parts by mass of modifier KH550, 210 parts by mass of two-component epoxy resin, 120 parts by mass of absolute ethanol, 1.3 parts by mass of dispersant BYK-W903, 1.2 parts by mass of wetting agent BYK-103 Parts, 0.8 parts by mass of coupling agent TMC-101, after high-speed dispersion treatment by a homogenizer, obtain a uniformly mixed functionalized graphene slurry.

[0080] (2) Mixing of functionalized graphene slurry and foaming liquid

[0081] Weigh 80 mass parts of methacrylic acid, 80 mass parts of methacrylonitrile, 0.7 mass parts of azobisisobutyronitrile, a mixture of n-butanol and tert-butanol (the mass ratio of the two is 1:1) 8 mass parts 3 parts by mass of acrylamide and 3 parts by mass of acrylamide are uniformly mixed, then the functionalized graphene liquid slurry prepared in step (1) is added, the system is uniformly dispersed by high-speed shear stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com