A lifting platform for logistics

A lifting platform and logistics technology, applied in the direction of lifting frame, lifting device, etc., can solve problems such as hidden safety hazards and the whereabouts of lifting trolleys, etc., and achieve the effects of efficient cargo loading, convenient loading, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

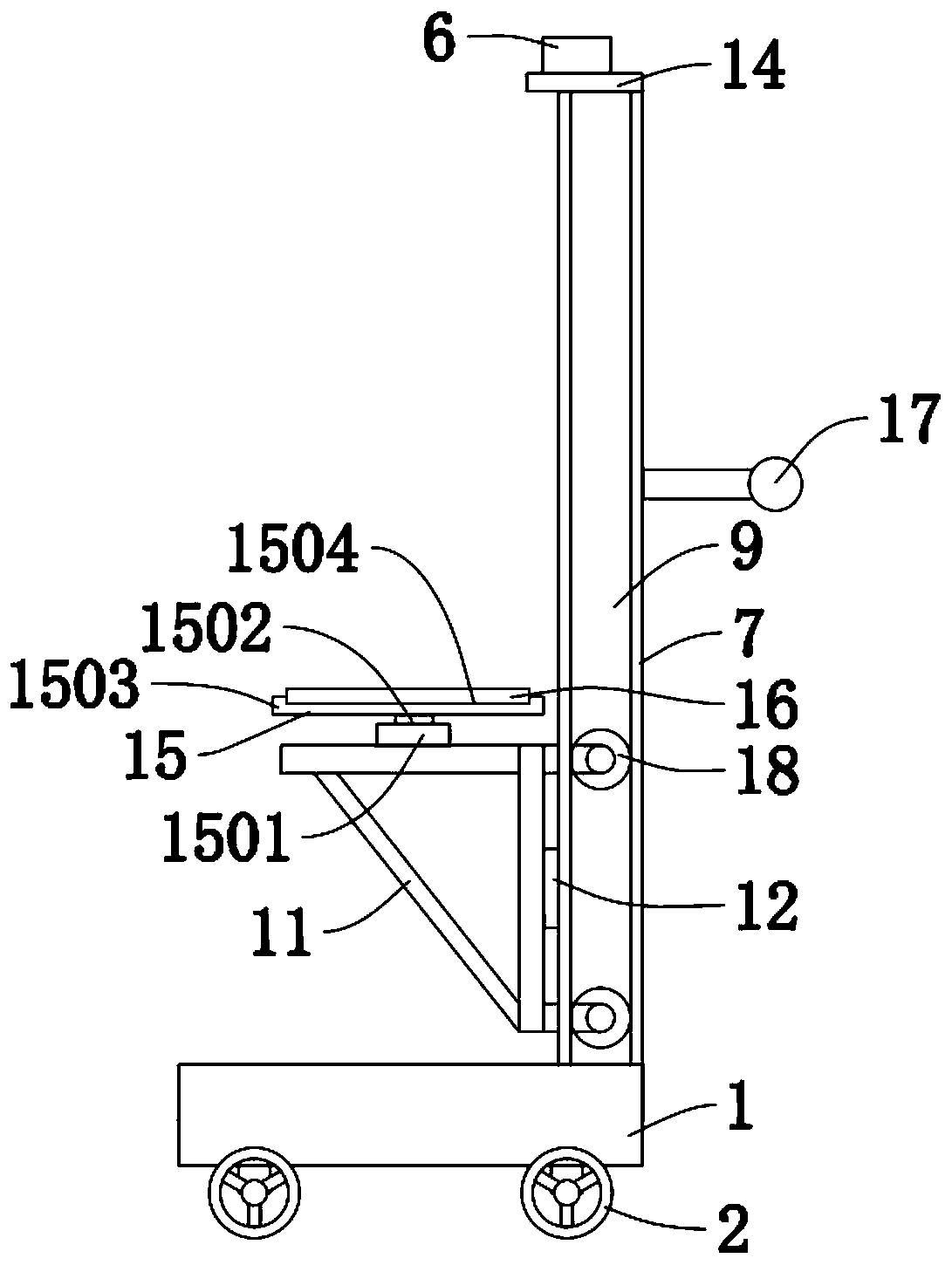

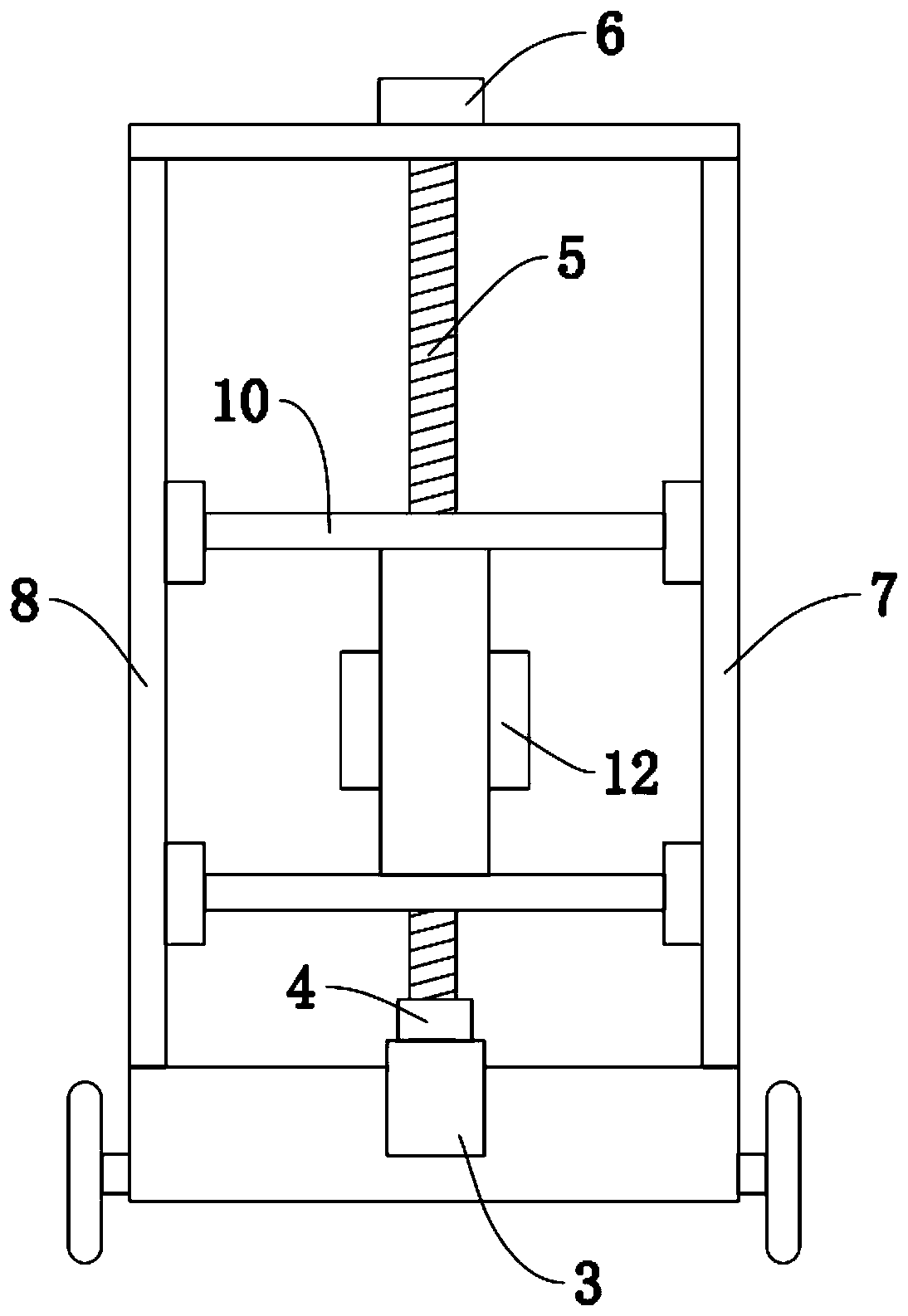

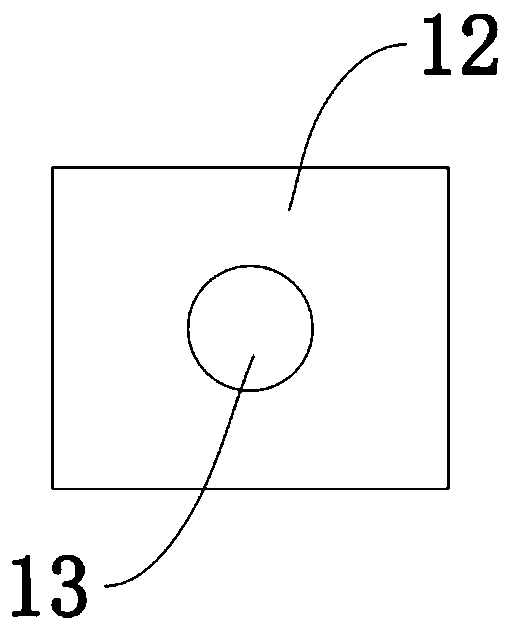

[0018] First implementation: see Figure 1-3 , a lifting platform for logistics, including a base 1, wheels 2 are installed on both sides of the base 1, and a first support rod 7 and a second support rod 8 are fixedly welded on the upper side of the base 1, so The inner sides of the first support bar 7 and the second support bar 8 are all provided with a slideway 9, and a pulley 18 is slidably connected on the slideway 9, and the pulley 18 can be on the inside of the first support bar 7 and the second support bar 8. Moving up and down in the slideway 9, the slideway 9 plays a position-limiting role, the pulley 18 is fixedly connected with a support beam 10, and one side of the support beam 10 is fixedly welded with a support frame 11, and the set support beam 10 and The support frame 11 can play the role of supporting goods, the right side of the middle part of the support frame 11 is fixedly connected with a slider 12, the slider 12 has a bolt hole 13, and a motor is embedded...

no. 2 approach

[0025] The second embodiment: a lifting platform for logistics, including a base 1, wheels 2 are installed on both sides of the base 1, and a first support rod 7 and a second support rod are hinged on the upper side of the base 1 8. A slideway 9 is provided inside the first support rod 7 and the second support rod 8, and a pulley 18 is slidably connected to the slideway 9, and a support beam 10 is fixedly connected to the pulley 18. One side of the support beam 10 is fixedly welded with a support frame 11, and the middle right side of the support frame 11 is fixedly connected with a slider 12, and the slider 12 is provided with a bolt hole 13, and the bottom side of the base 1 is embedded with a There is a motor 3, the upper output end of the motor 3 is connected with a screw mandrel 5 through a coupling 4, the screw mandrel 5 runs through the slider 12, and the screw mandrel 5 is threadedly connected with the bolt hole 13 on the slider 12, The upper end of the screw mandrel 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com