Automatic soldering apparatus suitable for integrated circuitry

An integrated circuit, automatic technology, applied in the direction of assembling printed circuits with electrical components, tin feeding devices, auxiliary devices, etc., can solve problems such as errors and affecting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] see Figure 1~3 , in an embodiment of the present invention, an automatic brazing device suitable for integrated circuits includes a bottom plate 1, a top plate 3, a turntable 7, a welding pipe 10, an injection pipe 18, and a material box 20; the bottom plate 1 is fixedly connected to a pillar 2, The upper end of the pillar 2 is fixedly connected to the top plate 3, and the drive motor 4 is installed under the top plate 3. Specifically, the drive motor 4 is fixedly connected to the motor base 5, and the motor base 5 is fixedly connected to the lower surface of the top plate 3 by bolts, and the output end of the drive motor 4 is connected to it in rotation. There is a driving shaft 6, the driving shaft 6 fits the lower end of the boom, the top of the boom is fixedly connected to the top plate 3, the driving motor 4 is connected to the power supply and the switch, and pressing the switch makes the driving motor 4 energized to drive the driving shaft 6 to rotate; the drivin...

Embodiment 2

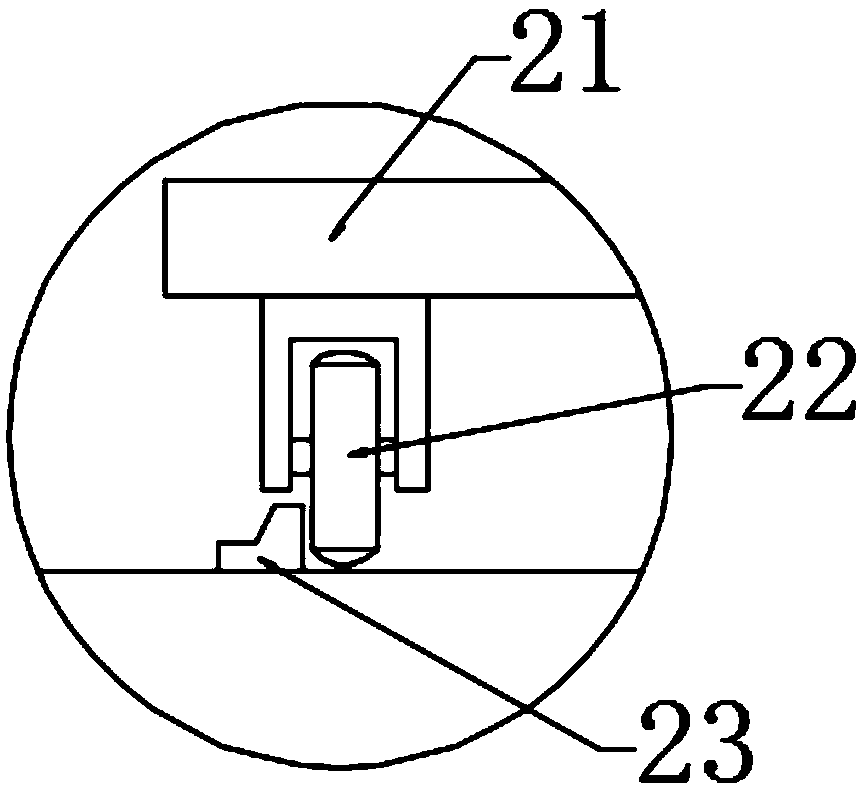

[0025] In order to make the technical solutions in this application more detailed and complete, now some supplements and explanations are made on the basis of the above-mentioned embodiment 1, so that the disclosure of the technical means adopted in this application is more sufficient, specifically, the supplements and explanations Part of the technical feature is that a workbench 21 is arranged under the welded pipe 10, and the four corners below the workbench 21 are rotatably connected with rollers 22. 23 restricts the moving direction of the rollers 22, so that the workbench 21 can only move in one direction, which helps the integrated circuit board to be transported smoothly in the assembly line and enters the next process.

[0026] The working principle of the present invention is: press the switch to make the drive motor 4 energized to drive the driving shaft 6 to rotate, and the rotating driving shaft 6 drives the turntable 7 to rotate, and then drives the storage gun 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com