Make-up powdery raw material grinding and refining device

A technology for cosmetics and powder, which is applied in the field of cosmetic powder raw material grinding and refining devices, which can solve the problems of complex devices, cohesion and blockage of cosmetic raw materials, high equipment costs, etc., and achieve smooth discharge, complete grinding process, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

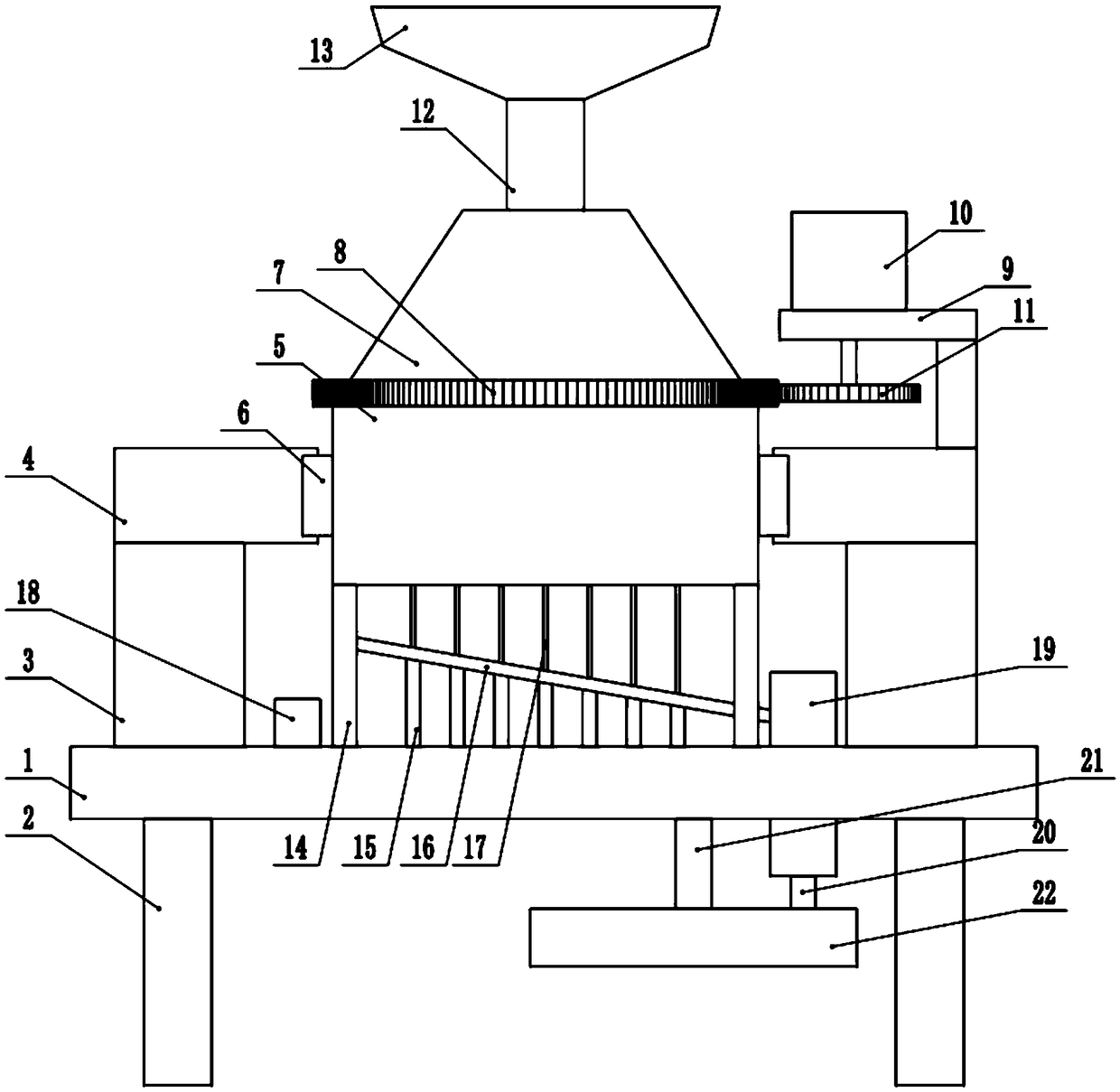

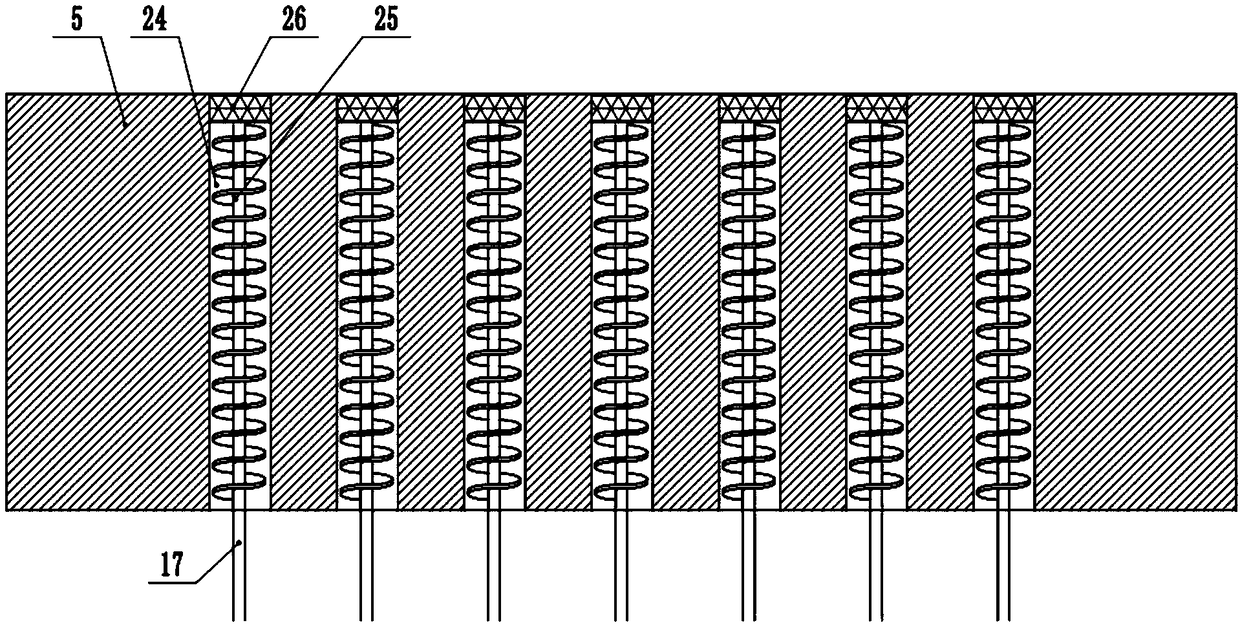

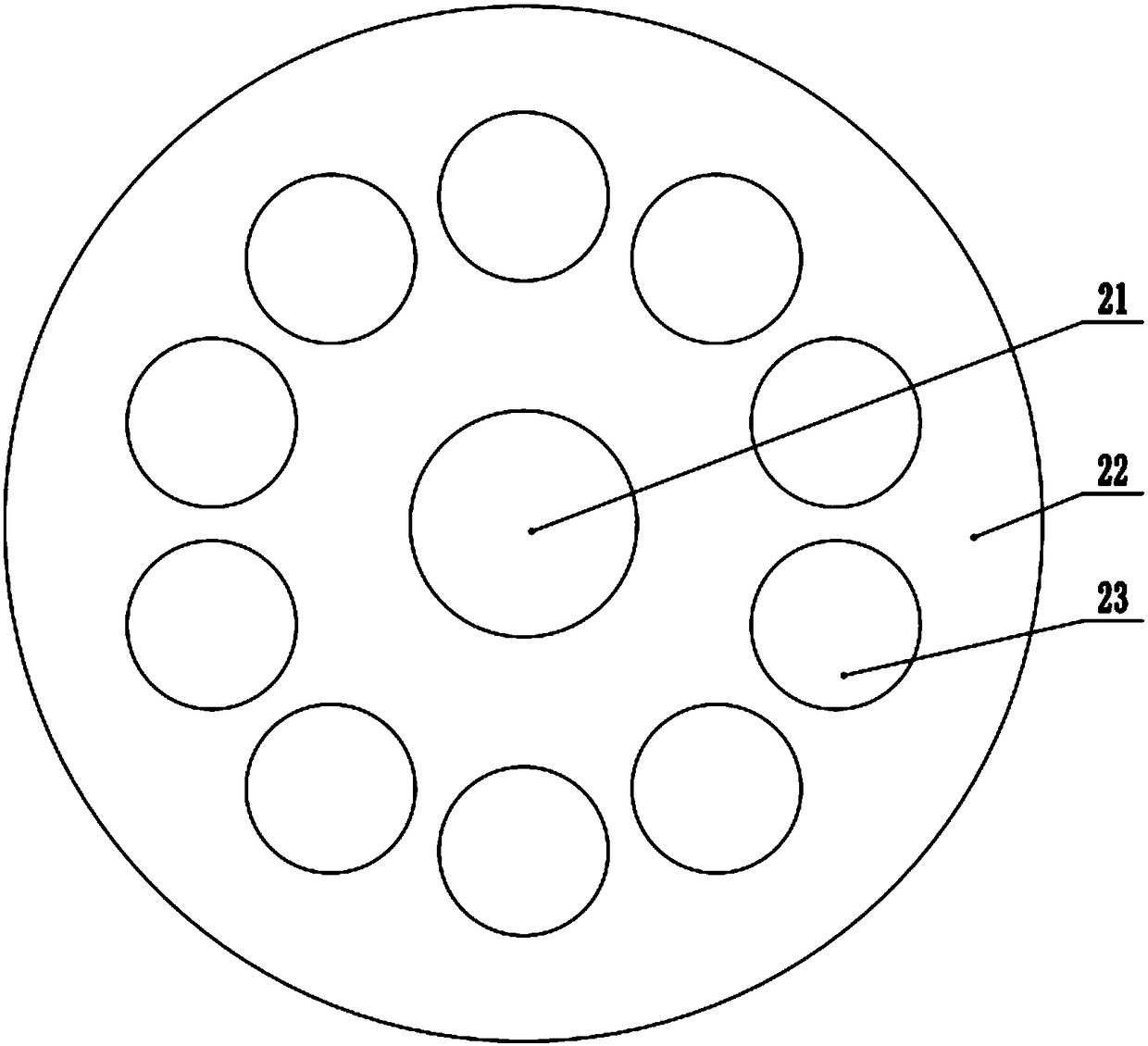

[0026] see figure 1 , a cosmetic powder raw material grinding and refining device, comprising a frame 1, the bottom four corners of the frame 1 are fixedly connected to the support legs 2, the top of the frame 1 is provided with a lower grinding disc 5, the lower grinding disc The top of 5 rotates and is provided with upper grinding disc 7, and the top of described upper grinding disc 7 is fixedly connected to feeding pipe 12, and the top of described feeding tube 12 is fixedly connected to feed hopper 13, and described lower grinding disc 5 is provided with output mechanism, The bottom of described lower millstone 5 is fixedly connected with support frame 14, and the below of described lower millstone 5 is provided with blanking plate 16, and described blanking plate 16 is inclined to be arranged, and the bottom of described blanking plate 16 and frame 1 The outer sleeve 15 is connected between them, the frame 1 on both sides of the lower grinding disc 5 is fixedly connected ...

Embodiment 2

[0030] see Figure 4 , the other content of this embodiment is the same as that of Embodiment 1, the difference is: the vibrating motor 27 is fixedly connected to the lower grinding disc 5, and the vibrating motor 27 generates an exciting force when it works, so that the cosmetic raw materials in the lower grinding disc 5 can be smooth output.

[0031] In the implementation process of the present invention, the cosmetic raw materials are first poured into the feed hopper 13, and the cosmetic raw materials enter the upper channel inside the upper millstone 7 through the feed pipe 12, and then start the first drive motor 10 and the second drive motor 18, The first drive motor 10 drives the upper grinding disc 7 to rotate, thereby grinding the cosmetic raw materials, and the cosmetic powder ground into fine particles falls into the discharge channel 24 through the mesh of the filter screen 26, and the second drive motor 18 drives the output rod 17 to rotate , so that the screw c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com