An industrial boiler waste gas dedusting device

A technology for industrial boilers and dust removal devices, which is applied to separation methods, lighting and heating equipment, water shower coolers, etc. Good, it is beneficial to the dust removal of exhaust gas and the effect of expanding the spray range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

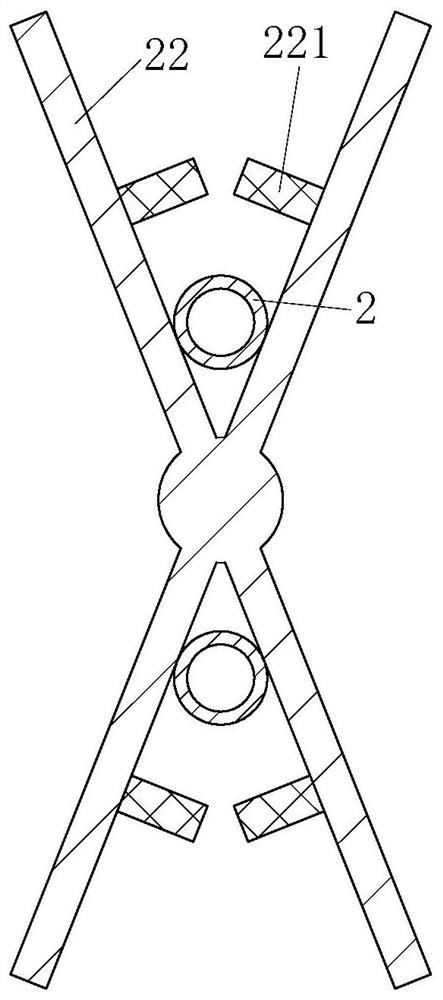

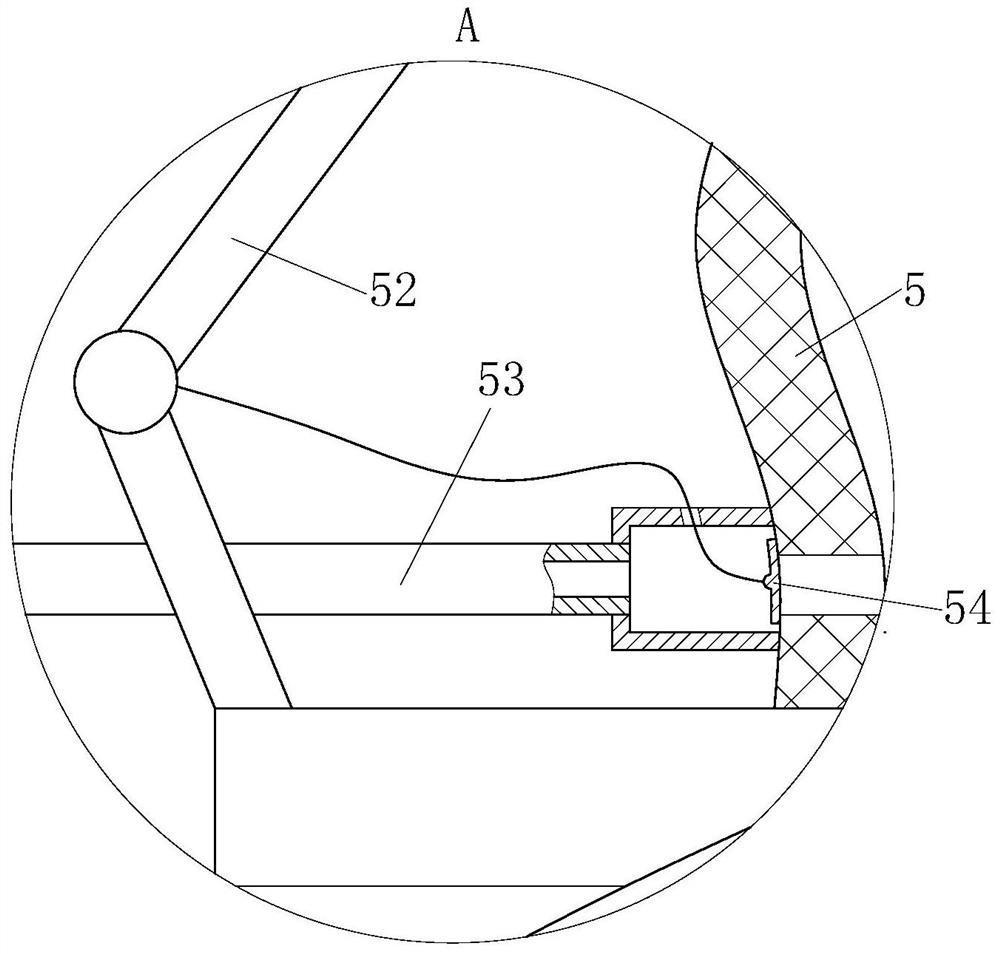

[0022] use Figure 1 to Figure 5 An industrial boiler waste gas dust removal device of the present invention is described as follows.

[0023] like Figure 1 to Figure 5As shown, an industrial boiler waste gas dust removal device according to the present invention includes a dust removal tank 1 and a controller. The dust removal tank 1 includes a tank bottom 11 with a hollow bottom, and the upper end of the dust removal tank 1 is provided with a water inlet 15 and a controller. The exhaust port 12, the lower end of the dust removal tank 1 is provided with a drain pipe 13; the drain pipe 13 is provided with a drain valve, and one end of the tank bottom 11 is provided with an exhaust gas inlet 14 penetrating the tank bottom 11, and the exhaust gas inlet 14 is connected to the tank bottom 11. The hollow tank bottom 11 is internally connected, the other end of the tank bottom 11 is provided with a ventilation port 112, and the tank bottom 11 is provided with a return spring and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com