water purifier fuse

A technology for fuses and water purifiers, applied in the field of fuses, can solve problems such as poor joint connection seal, easy falling off of connecting pipes, rising manufacturing costs, etc., and achieve good safety, low production costs, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

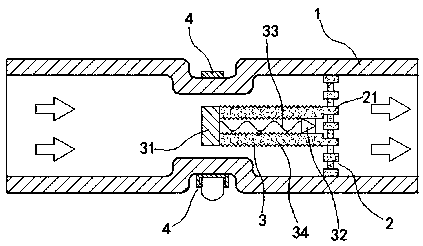

[0015] exist figure 1 In the shown embodiment, the safety pipe of the water purifier includes a pipe end and a pipe body 1, and the two pipe ends are connected between the water inlet pipe and the water purifier;

[0016] A blocking net 2 is arranged inside the tube body 1, and the blocking net 2 is perpendicular to the axis of the tube body 1; connected, each hollow pipe 21 communicates with each other;

[0017] A telescopic tube 3 is installed on the blocking net 2, the front end of the telescopic tube 3 is closed by a pressure plate 31, and the rear end is closed by a pressure limiting valve 32; the pressure plate 31 faces the flow of water; A tension spring 33 is installed on the axis, and the two ends of the tension spring 33 are respectively connected to the pressure bearing plate 31 and the pressure limiting valve 32; the telescopic tube 3 includes a hollow pipe wall 34, and the hollow pipe wall 34 communicates with the hollow pipe material 21; An adjustment band 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com