A multi-information fusion system and method for a combine harvester separating device

A combine harvester and multi-information fusion technology, which is applied in the field of multi-information fusion system of combine harvester separation device, can solve the problems of high labor intensity, low operation speed and efficiency, difficult failure rate, etc., and achieve structural Simple and compact, reducing the number of failures and avoiding the effect of interval range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

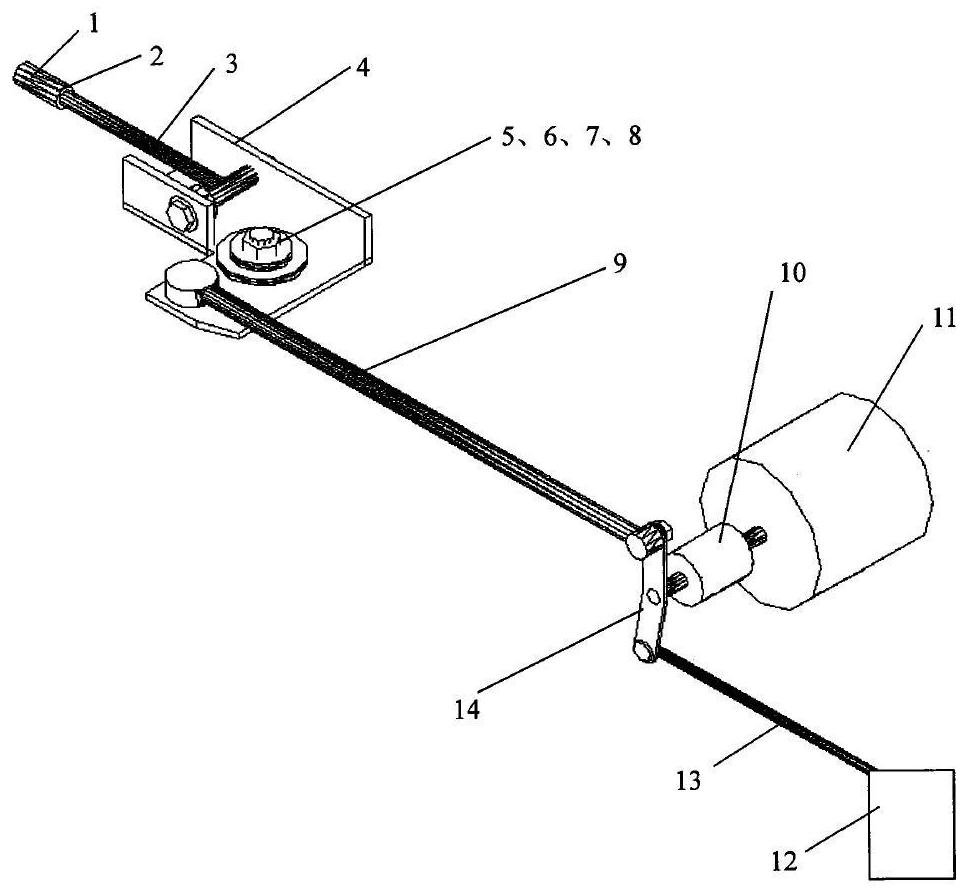

[0026] Such as figure 1 As shown, the speed regulating actuator 18 of the combine harvester 19 is composed of a manual speed regulating sub-mechanism and an automatic speed regulating sub-mechanism based on a hydraulic continuously variable transmission. Among them, the manual speed regulation sub-mechanism includes handle cover 1, handle 3, moving frame 4, bolt 5, friction plate 6, gasket 7, nut 8, pull rod 9, swing rod 14, hydraulic continuously variable transmission system 12 and connecting rod 13 . The automatic speed regulation sub-mechanism includes a motor 11 , a two-way overrunning clutch 10 , a swing rod 14 , a hydraulic continuously variable transmission system 12 and a connecting rod 13 . The button switch 2 is installed on the handle 3, and the handle 3 is also equipped with a rubber handle cover 1. The handle 3 is hinged with the moving frame 4, and the moving frame 4 is hinged with the support through the bolt 5, the friction plate 6, the gasket 7, and the nut 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com