A rivet for improving the offset of a laminated layer and a method for riveting and positioning a PCB before lamination

A rivet and riveting technology, which is applied in the direction of circuit board tool positioning, circuit lamination, laminated printed circuit boards, etc., can solve the problems of increasing the fixing force after riveting, low utilization rate of plates, and low efficiency, and achieves improvement. Production efficiency, avoiding the effect of low plate utilization and avoiding waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] This embodiment provides a rivet for improving the deflection of the laminated layer, and a method for riveting and positioning a PCB using the middle rivet before crimping.

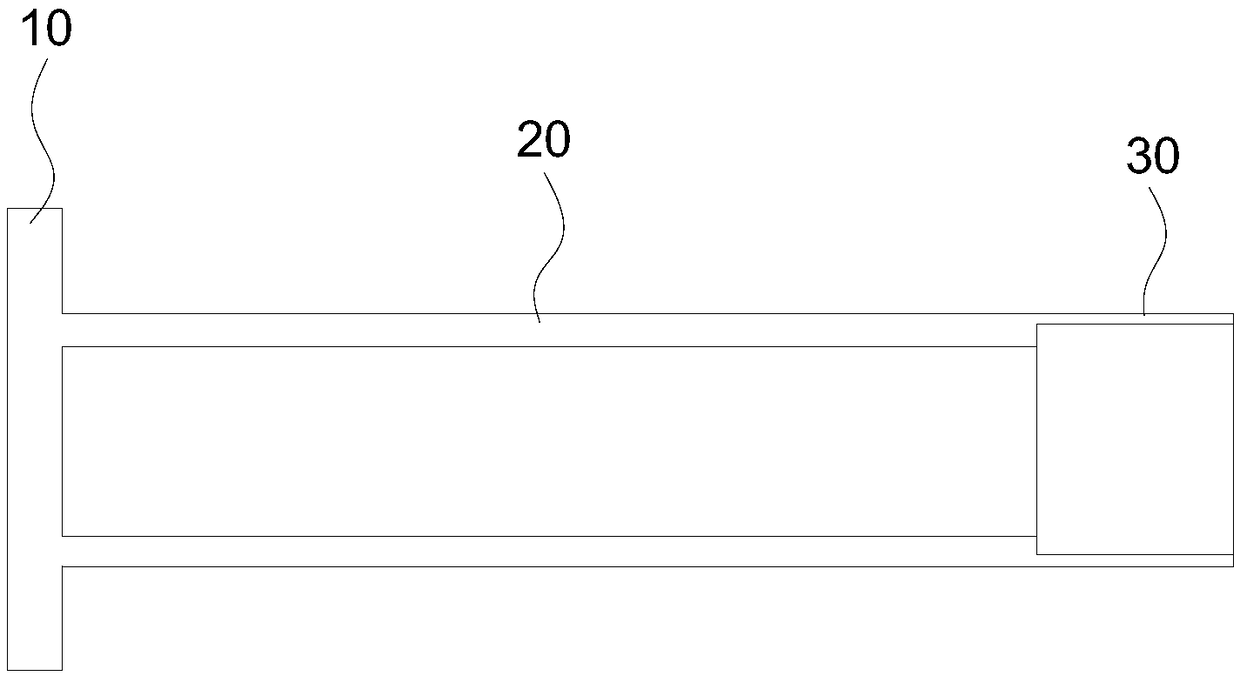

[0025] Such as figure 1 As shown, the rivet includes a nail head 10 and a nail shaft, and the nail head 10 is connected to the nail shaft. The nail bar is composed of a through section 20 and a blooming section 30 connected together, and the through section 20 and the blooming section 30 are both hollow cylinders. The wall thickness of the through section 20 of the rivet in this embodiment is 0.65mm, and the blooming section 30 is The wall thickness is 0.2mm, the length of the flowering section 30 is 1.5-2.0mm, and the length of the penetrating section 20 is 0.1mm shorter than the sum of the thickness of each core layer and the prepreg layer that need to be riveted and fixed in the pre-stacked structure, that is, the penetrating section The length of 20 is h-0.1mm, and h is the sum of the thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com