PTC heating device

A heating device and heating core technology, applied in the shape of heating elements, ohmic resistance heating parts, ohmic resistance electrodes, etc., can solve problems such as flashover and explosion, reduce the cost of aluminum materials, increase the heat dissipation area, and eliminate functional defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

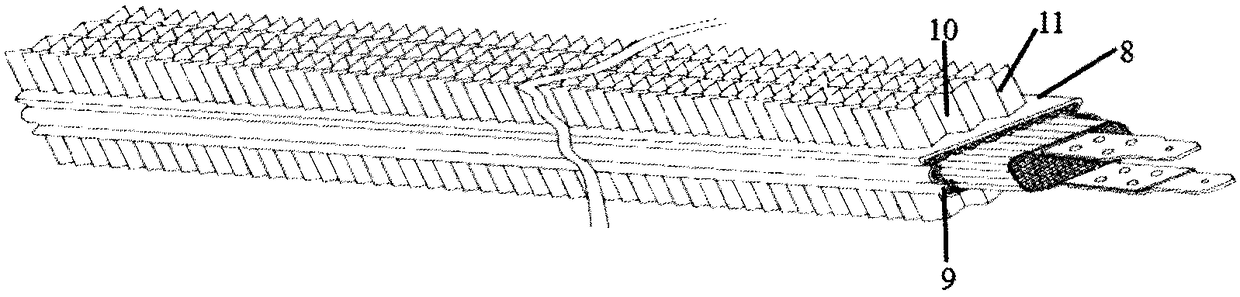

[0041] A PTC heating device, including a PTC heating core, a heat-conducting aluminum tube and a radiator, the heat-conducting aluminum tube 1 has a heat-conducting plane 8 and a pressing surface 9, and the wall thickness of the heat-conducting plane 8 exceeds the wall thickness of the pressing surface 9 3 times, the radiator includes cooling fins, and the preparation process of the heat-conducting aluminum tube is:

[0042] 1) Melt and soften the aluminum ingot in a special melting furnace;

[0043] 2) Stretching the softened aluminum liquid with a certain strength at the mouth of the furnace to the outside of the furnace through a special mold cavity, the mold cavity is located at the mouth of the melting furnace;

[0044] 3) The softened aluminum liquid is rapidly cooled in the uniform stretching process at room temperature to form an oblong hollow heat-conducting aluminum tube.

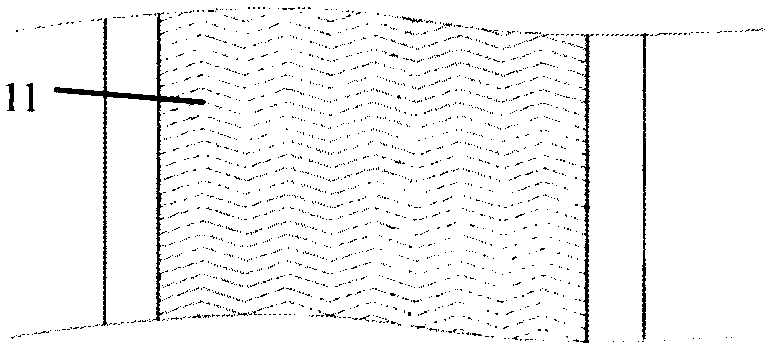

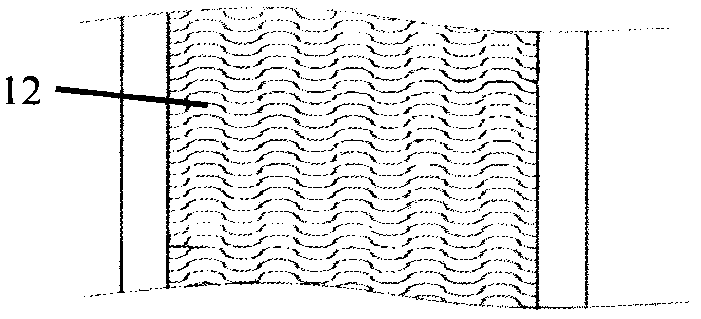

[0045] The heat sink 6 is a heat dissipation tooth piece 10 cut by shoveling at the wall thic...

Embodiment 2

[0050] A PTC heating device, including a PTC heating core, a heat-conducting aluminum tube 1 and a radiator, the heat-conducting aluminum tube 1 has a heat-conducting plane 8 and a pressing surface 9, and the wall thickness of the heat-conducting plane 8 exceeds the wall thickness of the pressing surface 9 3 times, the radiator includes cooling fins 10, and the preparation process of the heat-conducting aluminum tube 1 is:

[0051] 1) Melt and soften the aluminum ingot in a special melting furnace;

[0052] 2) Stretching the softened aluminum liquid with a certain strength at the mouth of the furnace to the outside of the furnace through a special mold cavity, the mold cavity is located at the mouth of the melting furnace;

[0053] 3) The softened aluminum liquid is rapidly cooled in the uniform stretching process at room temperature to form an oblong hollow heat-conducting aluminum tube.

[0054] The heat sink 6 is a heat dissipation tooth piece 10 cut by shoveling at the wa...

Embodiment 3

[0059] The utility model relates to an electrical appliance containing a PTC heating device.

[0060] The electrical appliance is at least one selected from air conditioners, heaters, hot air curtains, bathroom heaters, dehumidifiers, air purifiers, clothes dryers, new energy vehicle heaters or defoggers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com