A magnetic pole lead fixing structure for high-speed synchronous motor

A technology of synchronous motor and fixed structure, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of potential safety hazards and inconvenience, and achieve the effect of saving installation man-hours, simple installation and operation, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

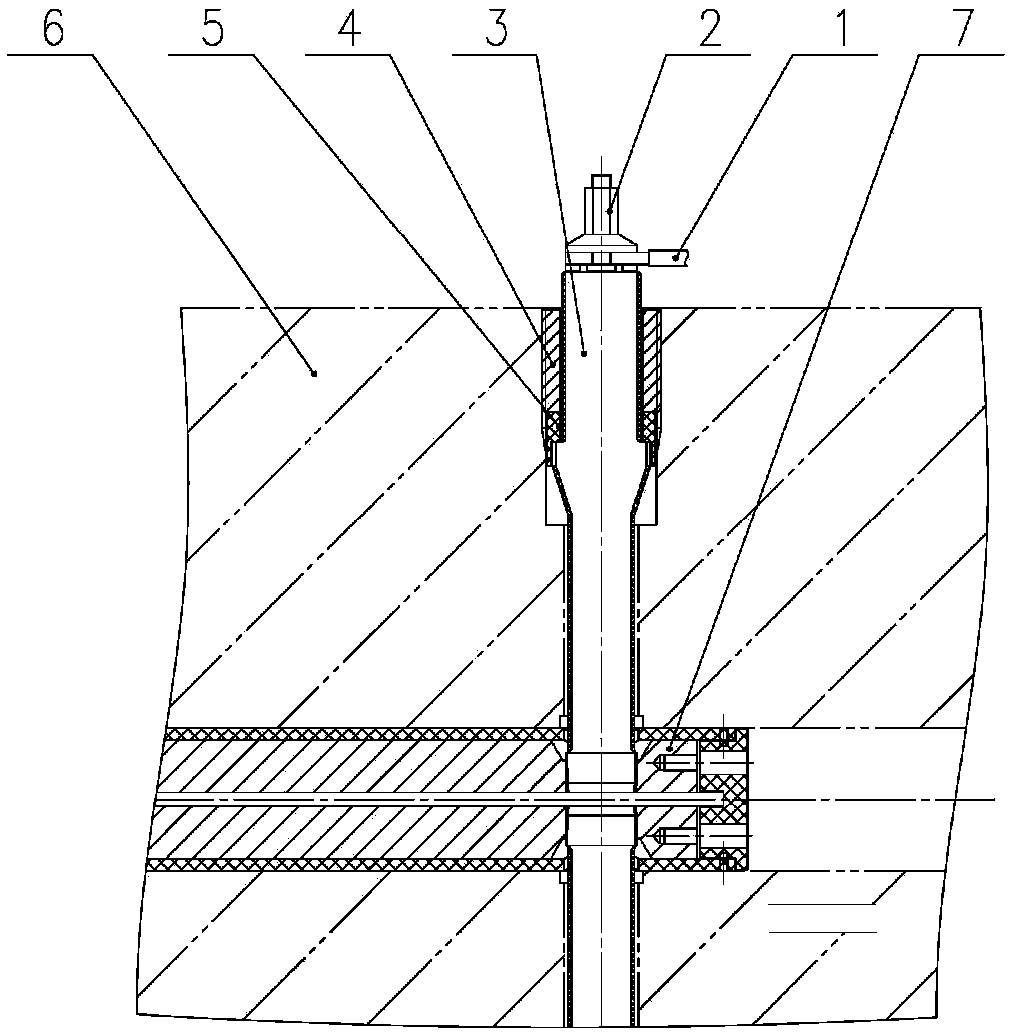

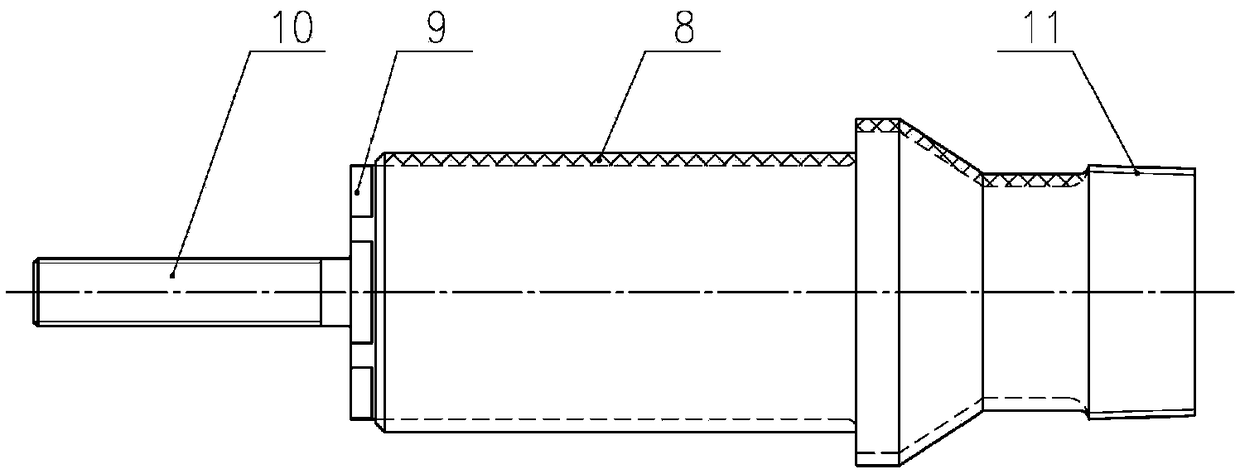

[0014] Such as figure 1 As shown, a high-speed synchronous motor rotor pole lead fixing structure is characterized in that: the conductive screw 3 is connected with the conductive rod assembly 7 arranged in the axial through hole of the rotating shaft 6 through the tapered thread 11, and the conductive screw 3 is connected through the threaded sleeve 4 1. The insulating sleeve 5 is fixed in the radial hole of the rotating shaft 6, the rotor magnetic pole lead wire 1 is fixed on the conductive screw rod 3 through the lock nut 2, and the lock nut 2 is electrically connected with the rotor magnetic pole lead wire 1. The conductive screw 3 wraps the insulating layer 8; the conductive screw 3 is electrically connected to the conductive rod assembly 7 and the rotor magnetic pole lead 1 respectively; figure 2 As shown, the conductive screw rod 3 is provided with: an outer hexagon 9, a common thread 10, and a taper thread 11. The insulating sleeve 5 is pressed onto the conductive sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com