Experiment device for fire resistance of structure

A technology of refractory experiments and refractory bricks, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high experimental cost, single device function, and large detection device size, so as to reduce experimental cost, simplify sample production, and increase convenience sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

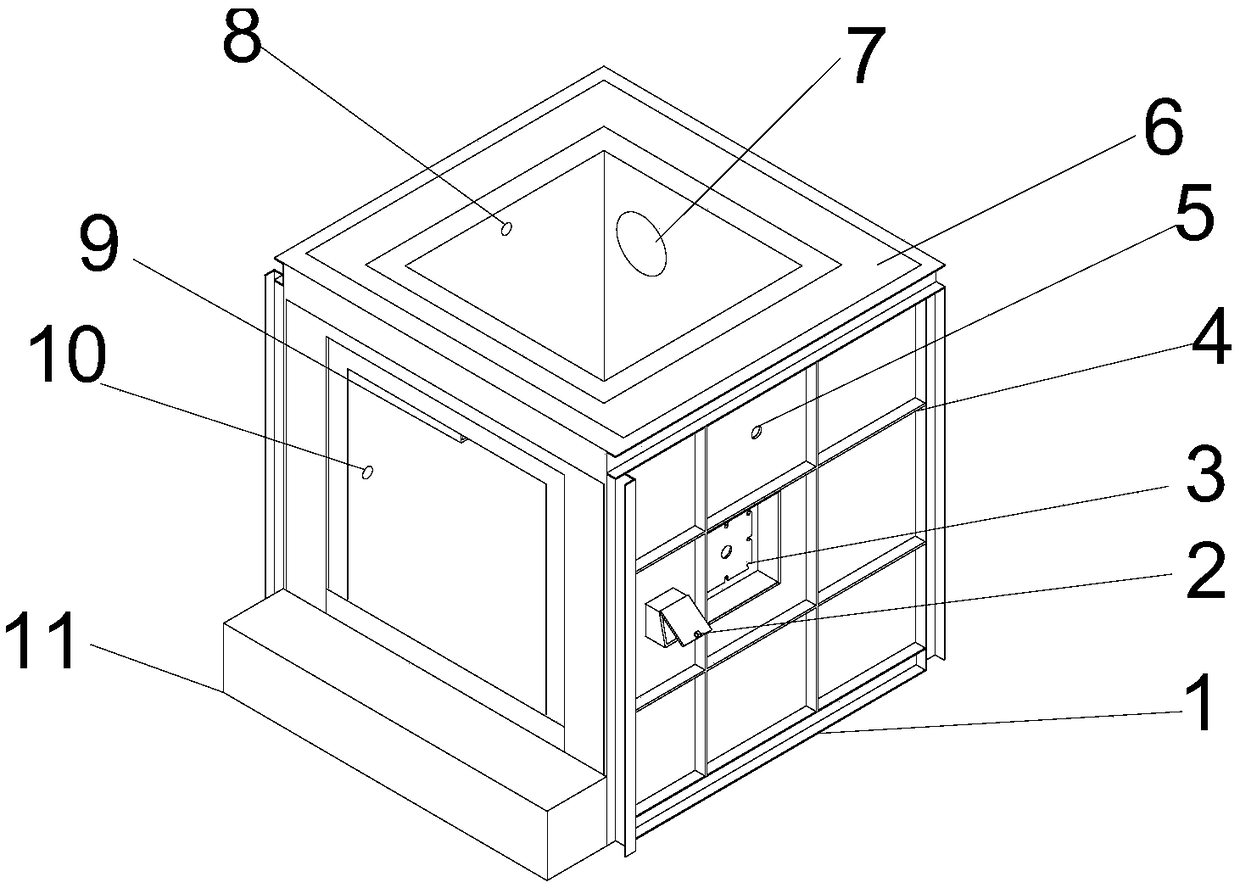

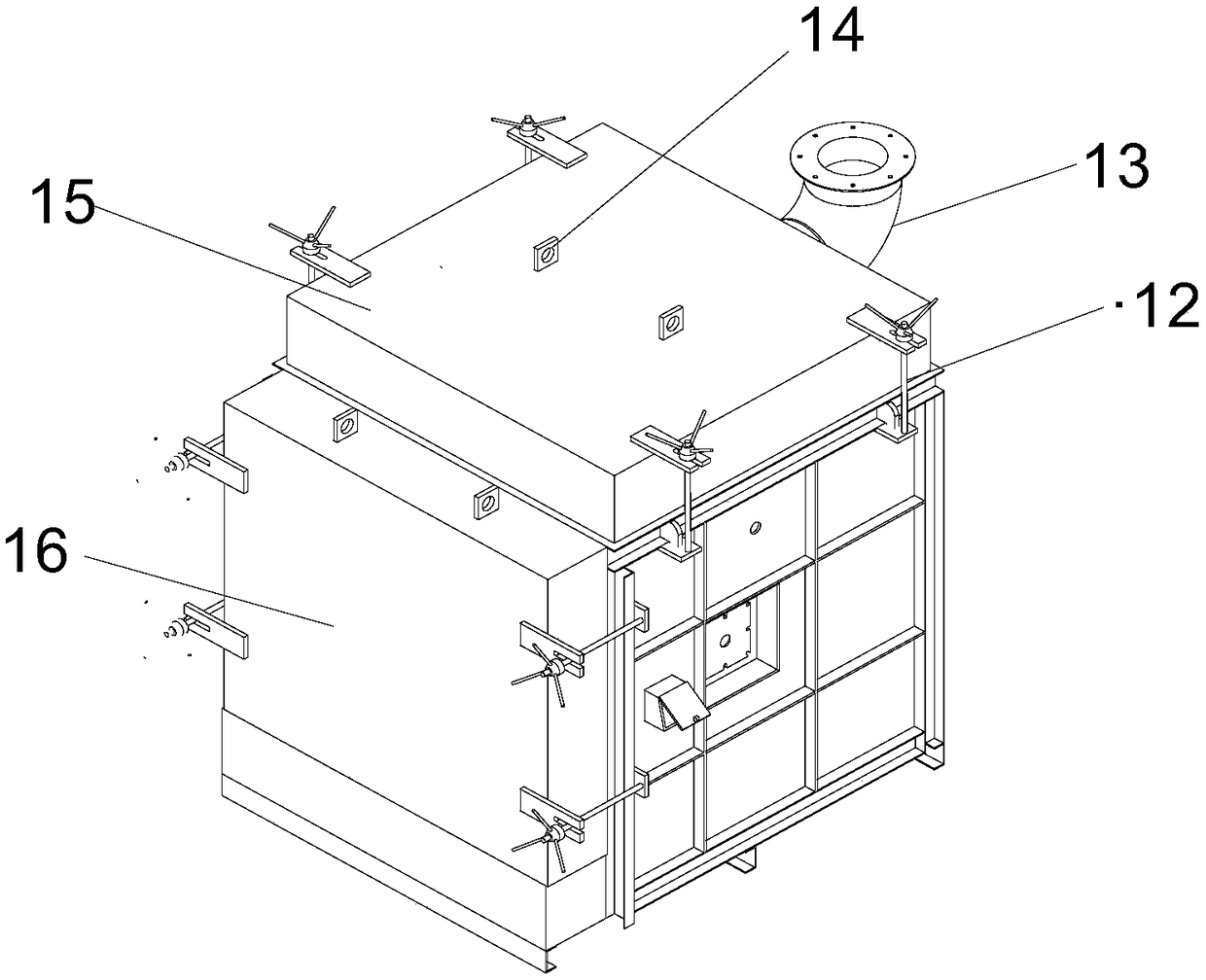

[0010] Such as Figure 1-2 As shown, a structural refractory experimental device of the present invention includes a furnace body. The inner size of the furnace body is 1000mm×1000mm×1000mm, the outer size (excluding the furnace door) is 1600mm×1600mm×1600mm, and the thickness of the furnace door is 300mm , the furnace body includes base 1, observation hole 2, burner installation port 3, shell 4, oxygen sensor interface 5, furnace lining 6, fan installation port 7, first pressure sensor interface 8, second pressure sensor interface 10, temperature sensor interface 9. Furnace door base 11, furnace door pressing device 12, air duct 13, hoisting opening 14, top furnace door 15 and side furnace door 16. The base 1 adopts multi-layer refractory bricks, insulation bricks and heat insulation bricks arranged vertically and horizontally. The inner laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com