Fixing-point stiffness testing method of front and rear covers of automobile

A test method and fixed point technology, applied in the field of vehicle inspection, can solve the problems of inconvenient operation, high labor intensity, human error, etc., and achieve the effect of ensuring accuracy, high degree of automation, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

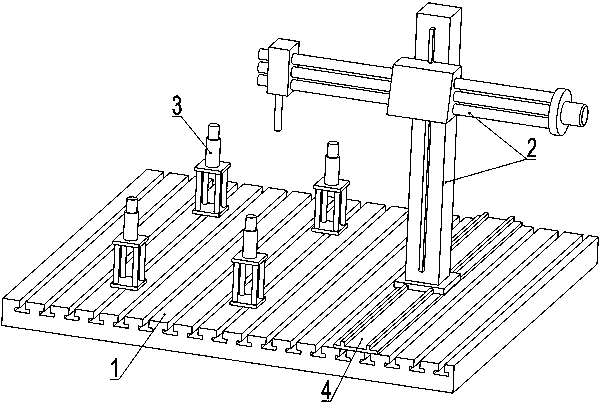

[0045] Step 1. Fix the car body-in-white: According to the restraint requirements of the front and rear covers of the car during the rigidity test of the fixed points of the front and rear covers of the car during the CAE analysis, adjust the restraint tooling so that the fixed restraint points of the front and rear covers of the car are consistent with the CAE analysis. Here, the body-in-white of the car is fully restrained using the body fixing bracket.

[0046] Step 2. Test preparation: Install the loading electric cylinder for the rigidity test of the fixed point of the front and rear covers of the car as a servo-driven loading unit, and arrange the loading electric cylinder and sensors according to the position and number of loading points during CAE analysis. The loading electric cylinder is connected with the loading rod, and the loading point is loaded through the loading rod, and the force sensor and the displacement sensor are installed on the loading rod. Select a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com