Device and method for monitoring deformation and stress of cement-based material in steaming and maintaining process

A cement-based material, steam-cured technology, applied in the direction of measuring devices, instruments, etc., can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

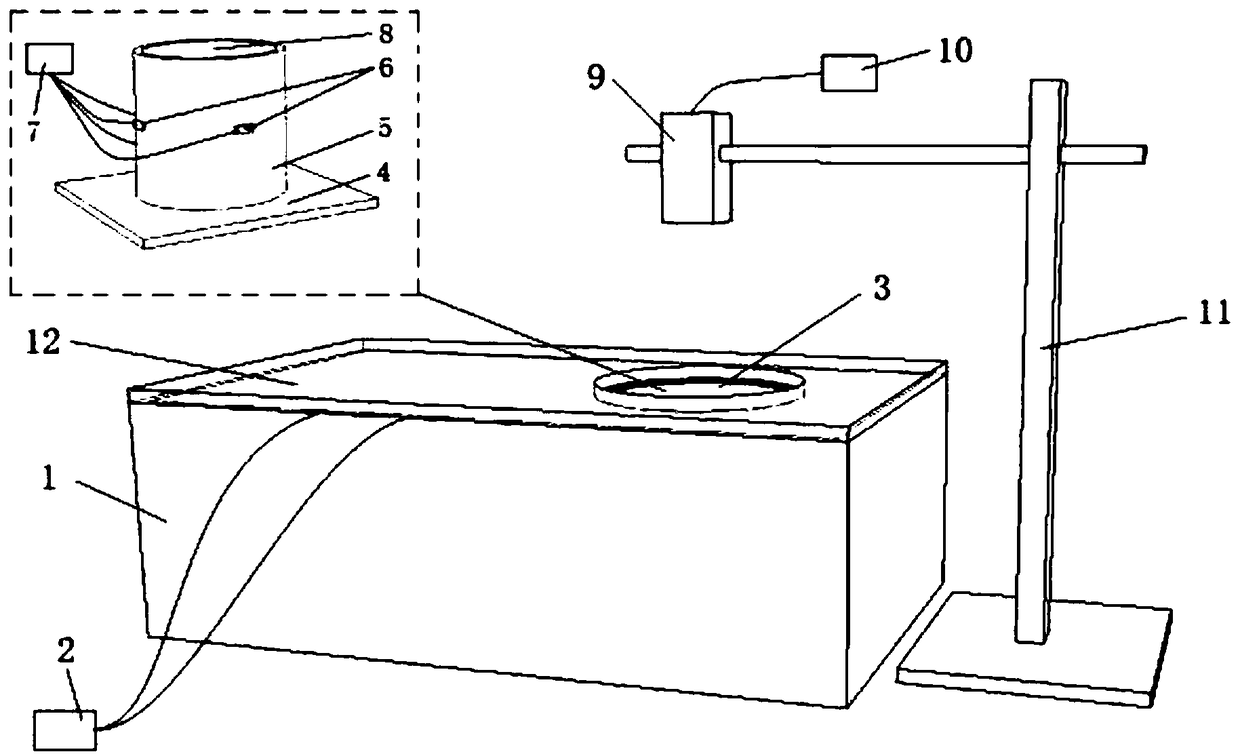

[0048] see Figure 1-Figure 3 , a test device for synchronously monitoring the swelling deformation and internal stress of cement-based materials in the thermal curing process of this embodiment, including a water bath temperature control heating system composed of a water bath box 1, a water temperature control system 2 and a plexiglass cover plate 12 , the steel ring restraint system 3 composed of the base plate 4 and the steel ring 5, the stress test system composed of the strain gauge 6 and the strain acquisition instrument 7, the swelling deformation composed of the laser displacement sensor 9, the laser displacement acquisition instrument 10 and the bracket 11 test system. Water bath temperature control heating system, the water bath box 1 is rectangular in shape, adopts double-layer insulation box, and the material is stainless steel. The temperature control range of the water temperature control system 2 is about 60°C, the temperature control accuracy is ±3°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com