Sealing structure and method of in-plane prestressed reinforcement channel of segmental beam splicing

A technology of prestressed tendons and sealing structures, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as poor sealing effect, and achieve the effects of preventing stress corrosion, avoiding water and ventilation, and improving durability and stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

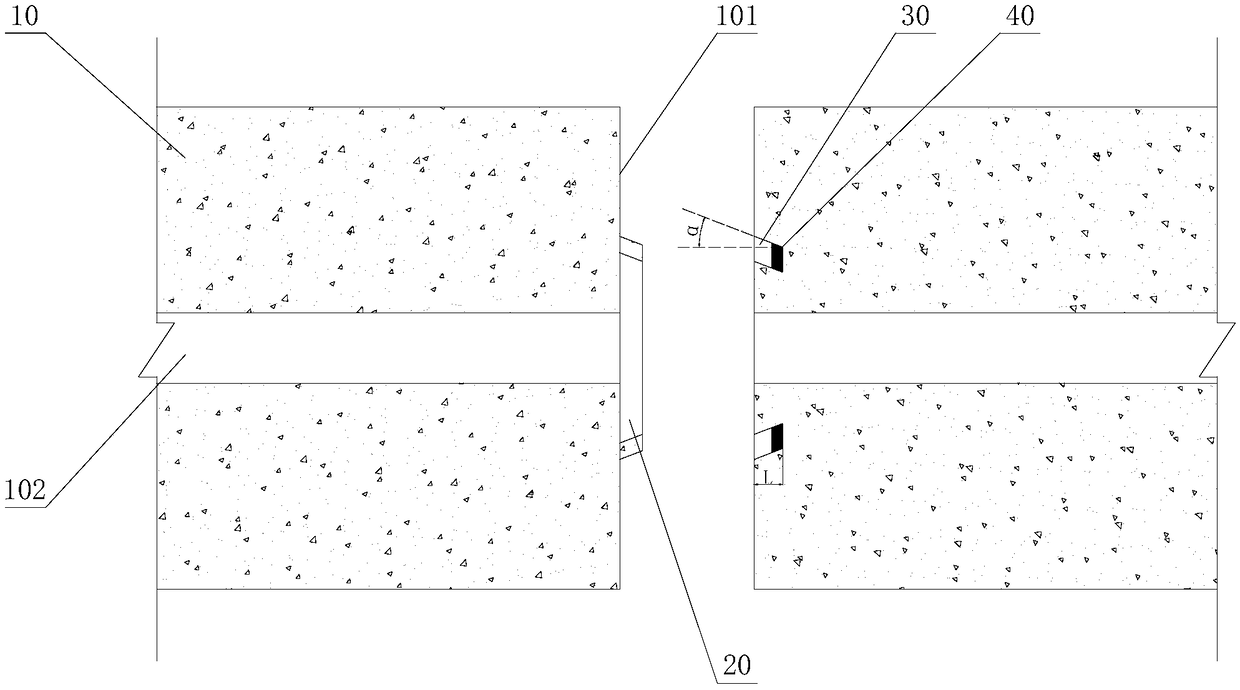

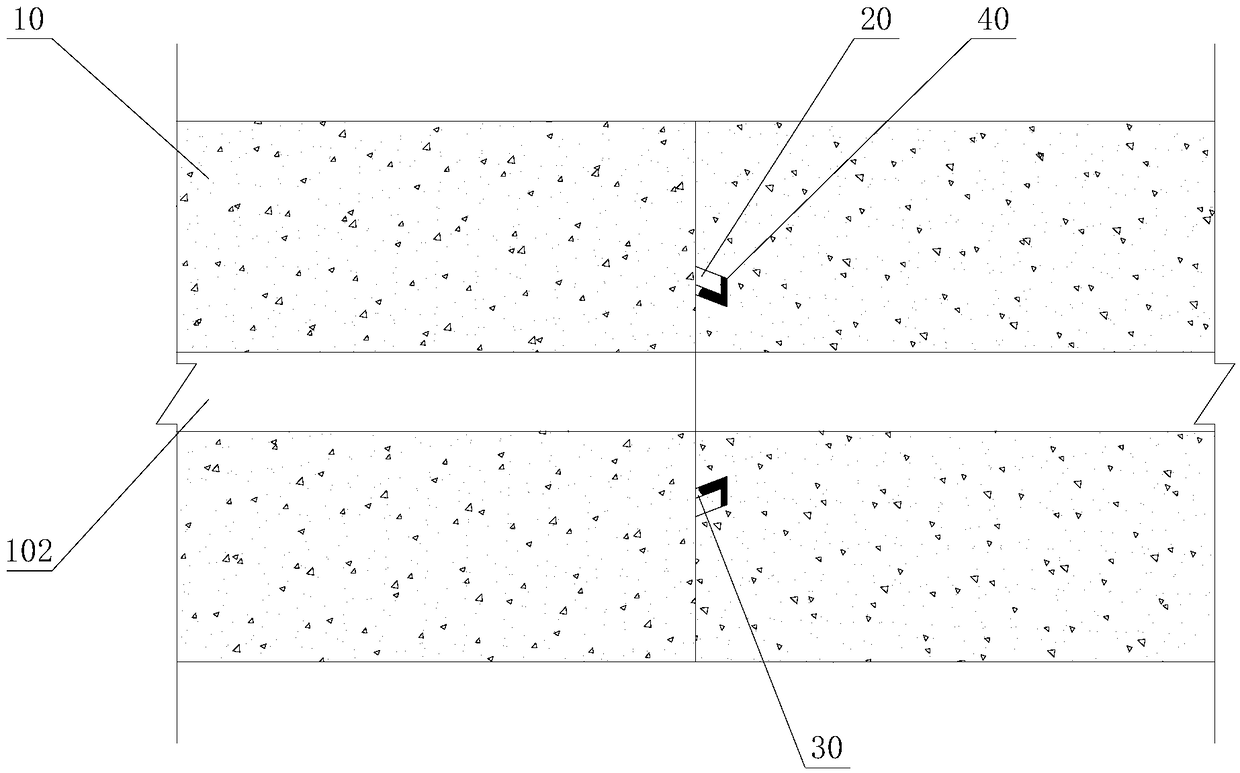

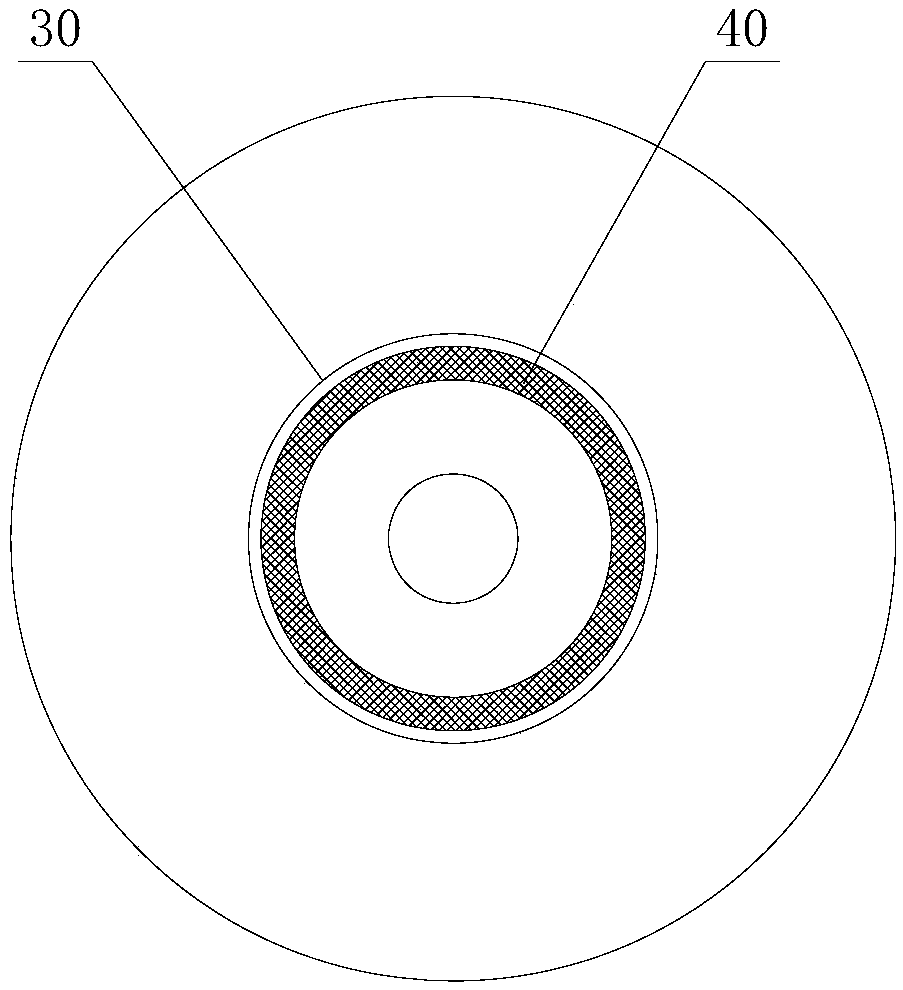

[0018] In order to solve the problem of the poor sealing effect of the prestressed tendon channels of the existing segmental beams, the present invention provides a sealing structure and method for the prestressed tendon channels in the splicing surface of the segmental beams, which can greatly improve the sealing effect and effectively improve the performance of bridges. The corrosion resistance of the prestressed tendons improves the stiffness and life of the bridge. In order to further illustrate the structure of the present invention, in conjunction with accompanying drawing detailed description is as follows:

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com