Synergistic damping, shock-isolating mounts for increased speed locking force

A speed-locking and vibration-isolation bearing technology, which is applied in the field of vibration-isolation bearings and collaborative shock absorption, can solve the impact of vibration reduction and isolation functions of integrated bridges, the large size of the speed locker cylinder, and the stiffness of composite materials that are easy to fail, etc. problems, to achieve the effect of large size improvement, large damping force, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in combination with specific embodiments.

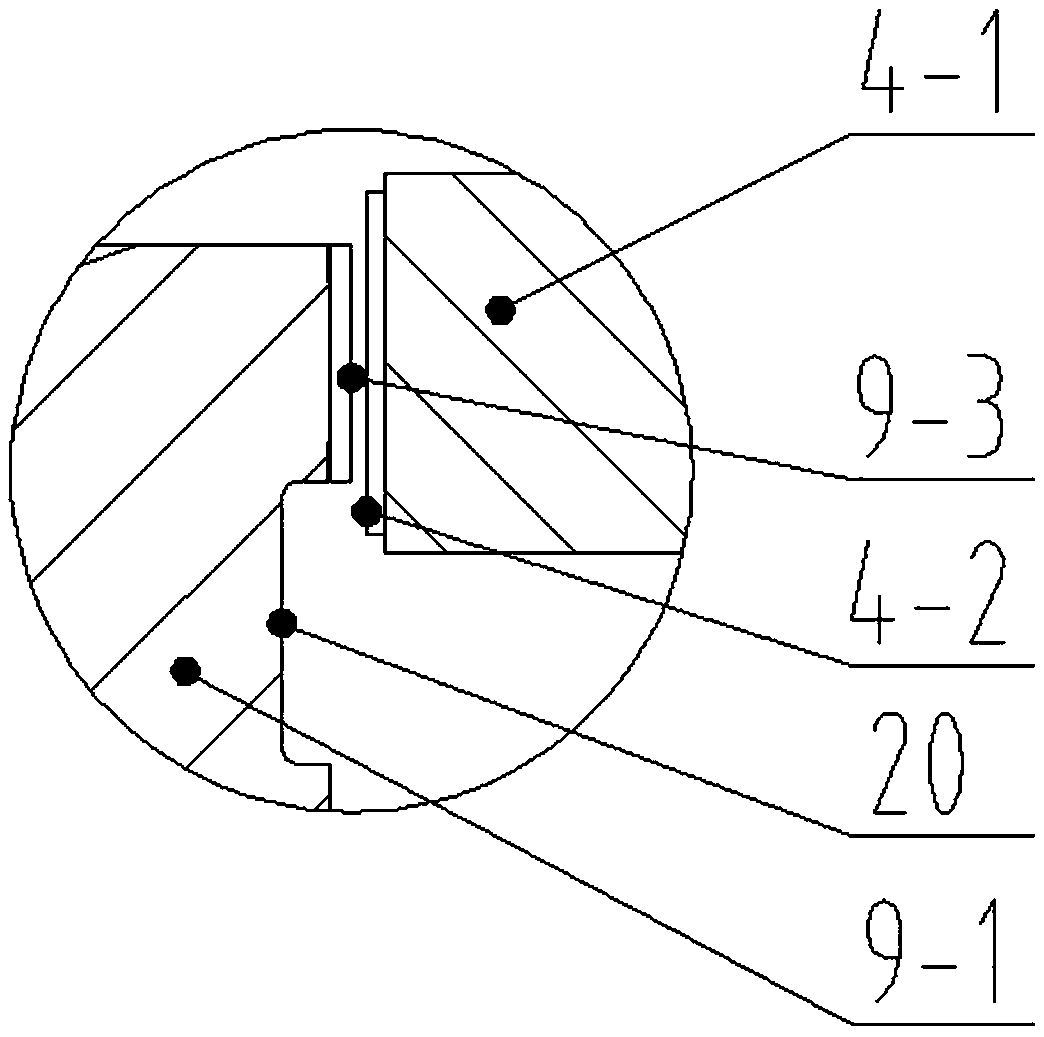

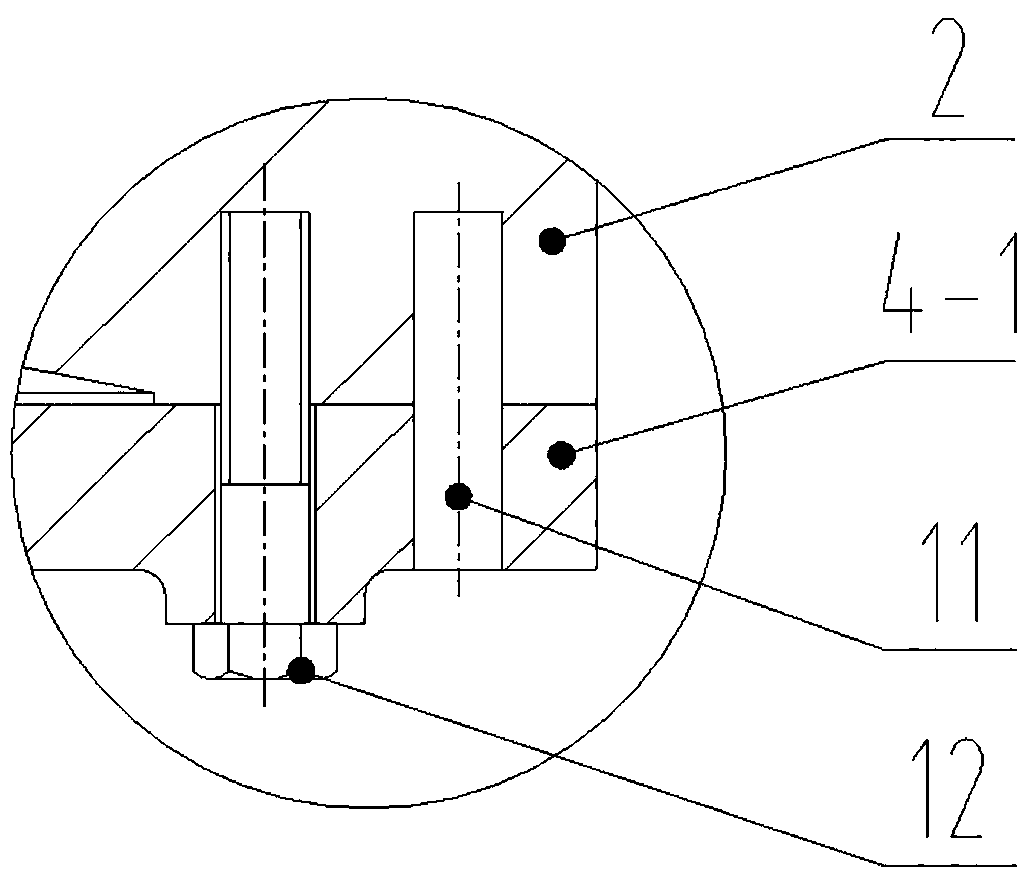

[0050] The present invention relates to a synergistic shock absorbing and shock-isolation support for improving speed locking force, comprising an upper seat plate 2, a middle seat plate 9-1 and a lower seat plate 10, the bottom surface of the upper seat plate 2 is an upper concave spherical surface, and the middle seat plate 9-1 1. The top surface is a concave spherical surface. A hollow spherical cavity is formed between the upper seat plate 2 and the middle seat plate 9-1. A spherical crown liner 6 with convex spherical surfaces on both upper and lower surfaces is provided. The diameter of the upper ball is not smaller than the diameter of the lower ball. The spherical crown liner 6 can swing back and forth in the hollow spherical cavity, and the limit damping displacement does not exceed the design range of the spherical cavity.

[0051] Two front and rear piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com