Continuously-operated centrifugal sludge dewatering device

A technology of centrifugal dehydration and dehydration device, which is applied in the field of centrifuges, and can solve problems such as low production efficiency, poor dehydration effect, and inability to work continuously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

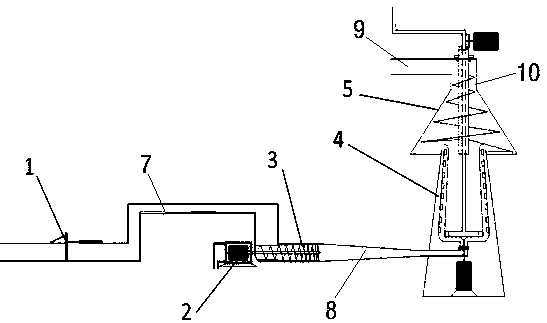

[0033] Refer to attached Figure 1-7 A continuously operating sludge centrifugal dewatering device shown is a continuously operating sludge centrifugal dewatering device, and the sludge centrifugal dewatering device includes a filter device 1, a press crushing device 3, a sludge dewatering device 4 and Silt collecting device 5, wherein:

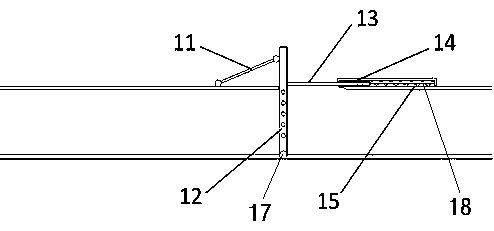

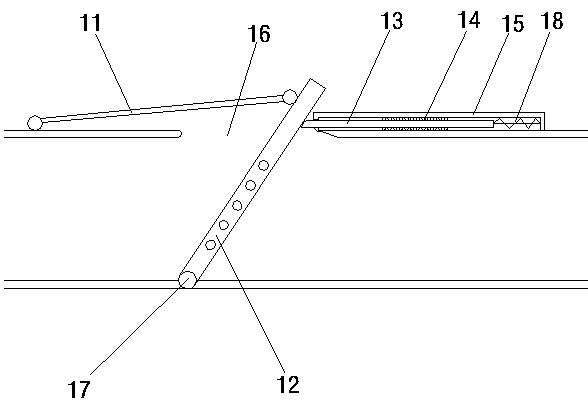

[0034]Described filtering device 1 is arranged on the mud pipeline one 7, and described filtering device 1 comprises filter panel 12, telescopic spring 11, sliding baffle plate 13 and elastic element 15, and described mud pipeline one 7 is provided with opening 16, so The filter panel 12 is vertically inserted into the opening 16, the bottom end of the filter panel 12 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com