Amphibious vertical sand discharging pump

An amphibious and sand-discharging pump technology, which is applied to non-variable pumps, pumps, components of pumping devices for elastic fluids, etc., can solve the problems of non-amphibious use, motor damage, and long lift. To achieve the effect of solving the excessive internal pressure of the pump, increasing the lift and solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific details in the description of the present invention are only for fully understanding the embodiments of the present invention, but those skilled in the art should know that the implementation of the present invention is not limited to these details. In addition, well-known structures and functions are not described or shown in detail to avoid obscuring the gist of the embodiments of the present invention. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention in specific situations.

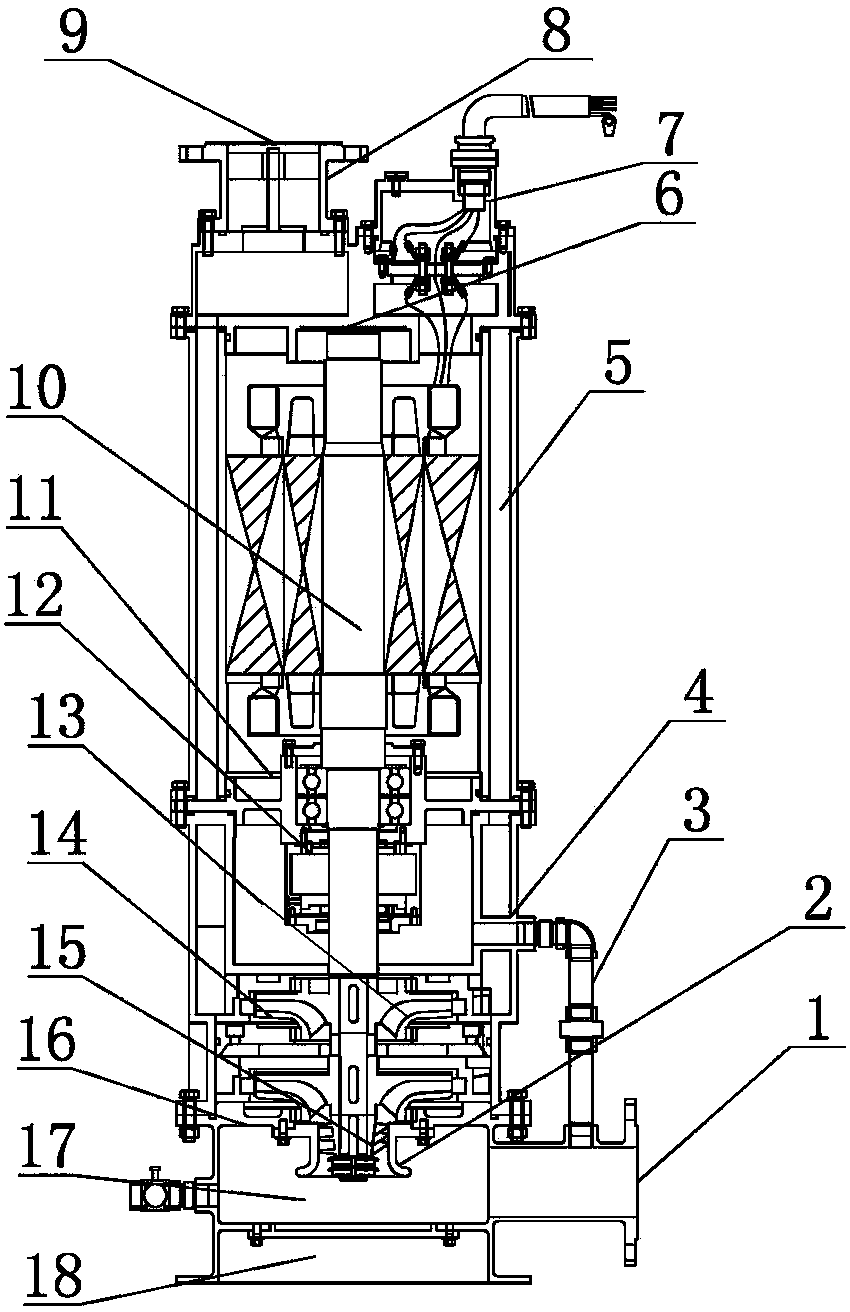

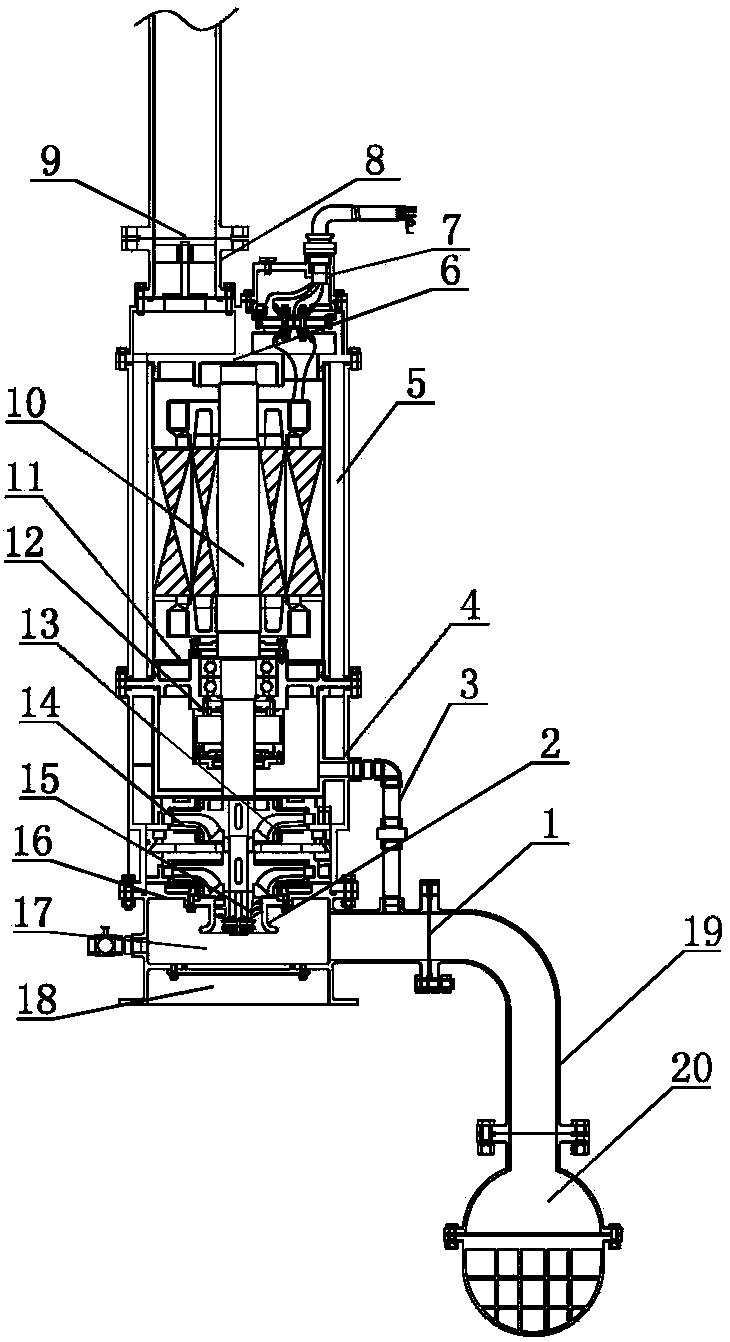

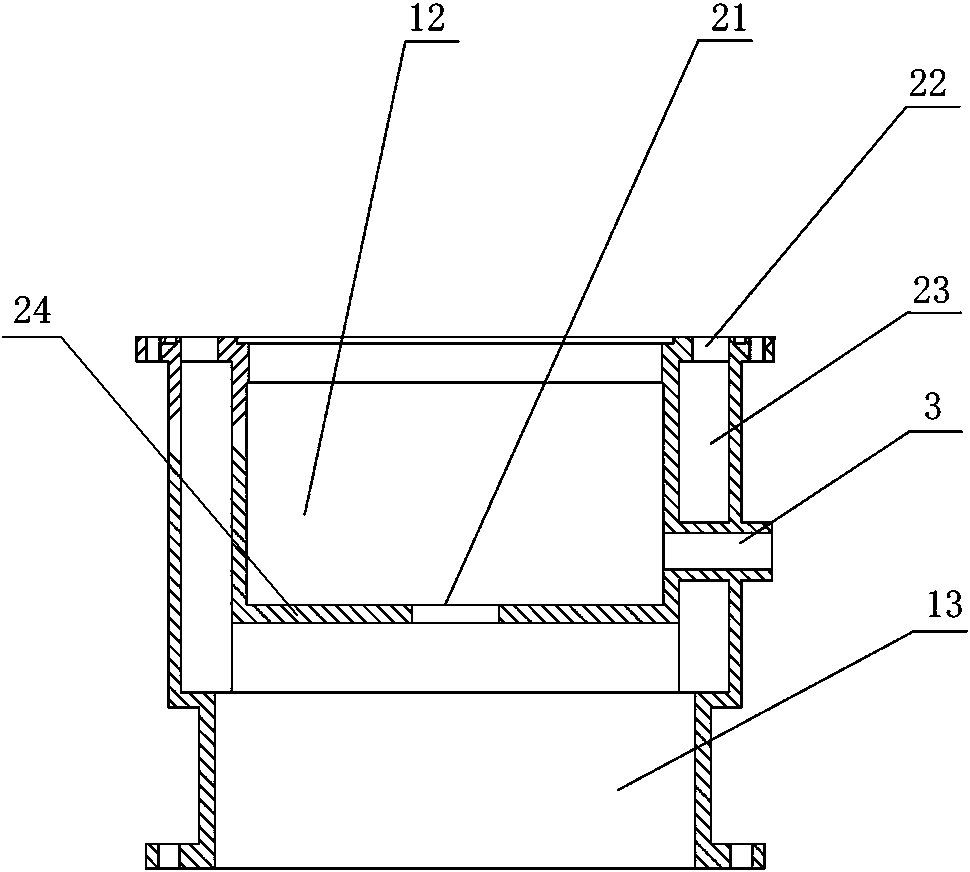

[0019] Specific embodiments of the present invention: the amphibious vertical sand discharge pump includes a top cover, a pump body 5, an upper bearing seat 6, a middle bearing seat 11, a water inlet section 4, a lower bearing seat 16 and a base 18, A water pump motor 10 is provided between the upper bearing seat 6 and the middle bearing seat 11, a water inlet 1 is provided on one side of the base 18, and a water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com