Door sheet packing equipment and packing method thereof

A packaging equipment and door panel technology, applied in the field of door panel packaging equipment and its packaging, can solve the problems of excessive manual operation process, low packaging efficiency, and complicated operation process, and achieve the effect of simplifying the operation process and improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

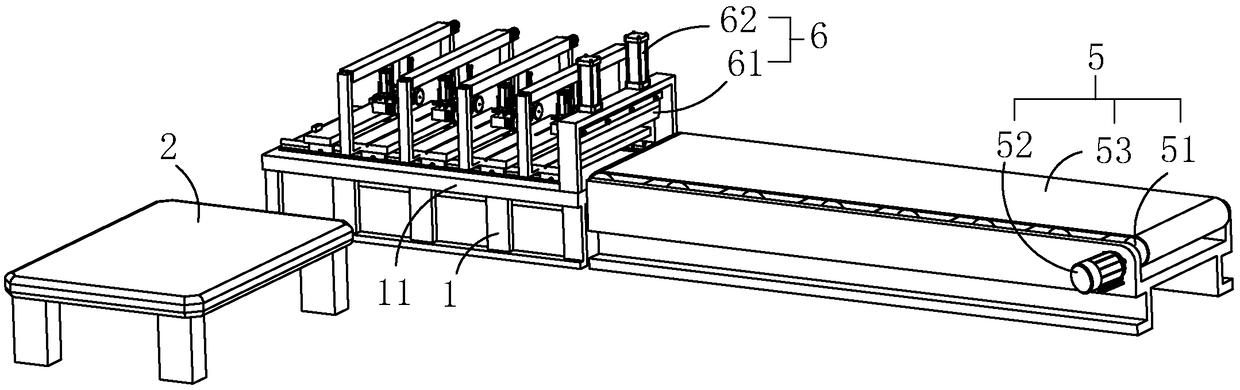

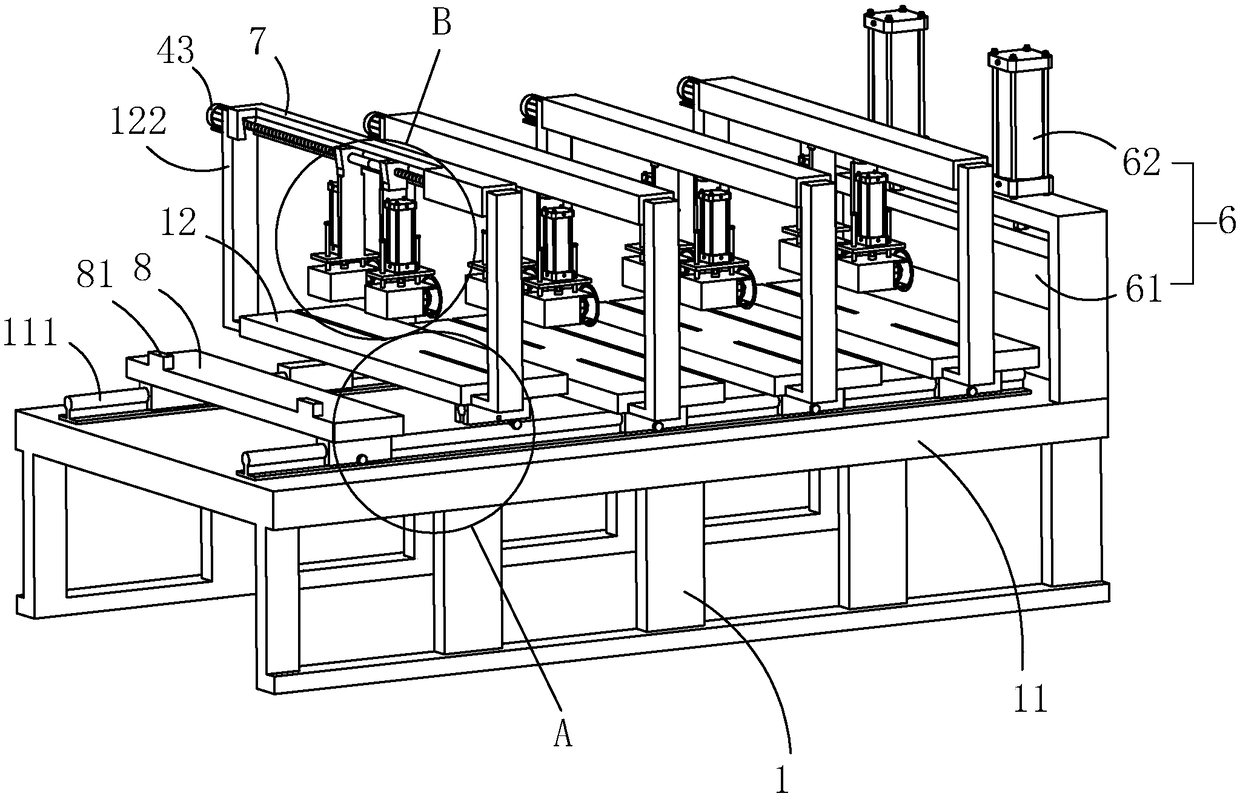

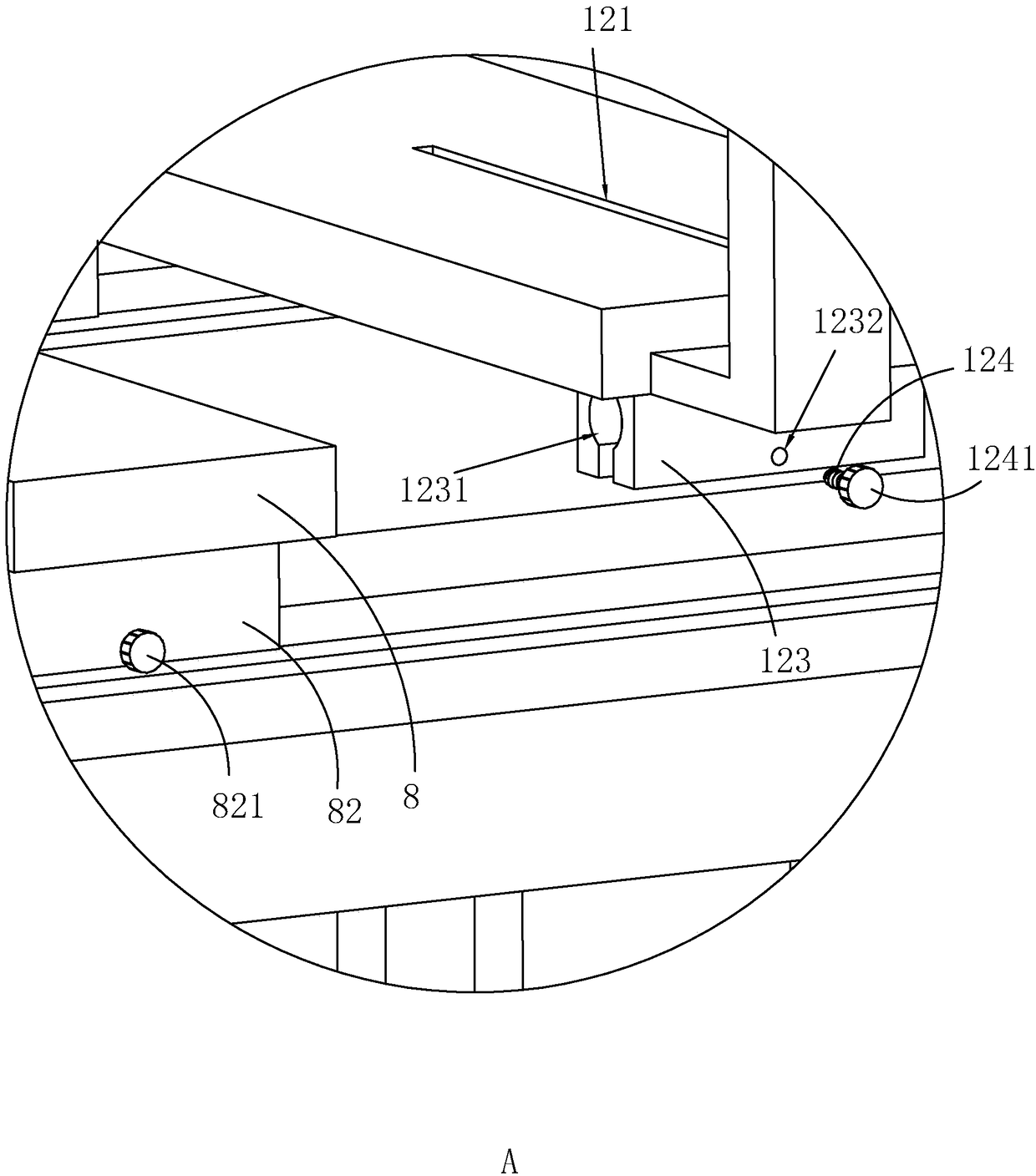

[0043] Such as figure 1 , 2 As shown, a door panel packaging equipment includes a frame 1 and a workbench 2 arranged on one side of the frame 1, a fixed table 11 is fixedly arranged on the frame 1, and four pieces for placing cardboard are arranged on the fixed table 11. Working block 12, the length of working block 12 is greater than the width of cardboard, and working block 12 is a rectangular block.

[0044] The frame 1 is also provided with a belt conveyor 5 that is used to transport the cardboard to the work block 12. The belt conveyor 5 includes a rotating roller 51, a conveying motor 52 and a belt 53. The rotating roller 51 is arranged on the frame 1 in rotation. A plurality of rollers 51 are arranged along the conveying direction, a conveying motor 52 is fixedly arranged on the frame 1 and the output shaft of the conveying motor 52 is coaxially fixedly connected with any rotating roller 51, and a belt 53 is wound on the rotating roller 51.

[0045] Such as figure 1 ...

Embodiment 2

[0060] A door panel packaging method, comprising the following steps:

[0061] S1. Carrying out pretreatment on the cardboard by any one of the door panel packaging equipment of claims 1-9;

[0062] S11, the worker places the cardboard on the belt conveyor 5, and cuts the cardboard into the required size through the cutting device 6;

[0063] S12, start the driving mechanism and the cutting device to cut the cardboard;

[0064] S2. After the cardboard is cut, the worker manually removes the cardboard from the work block 12 and places it on the workbench 2;

[0065] S3. The worker places the door panel on the cardboard, and manually folds the cardboard to form a box structure so that the cardboard completely covers the door panel;

[0066] S4. Seal the carton with tape, and the tape is BOPP tape.

[0067] Operation process: Workers place the cardboard on the belt conveyor 5. The cardboard is made of corrugated cardboard. The cardboard is cut into the required size by the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com