Double-layer stacking device for packaging bag arranging production line of multi-column packaging machine

A packaging bag and column packaging technology, applied in the field of packaging bag sorting production line, can solve problems such as heavy slippage, secondary pollution of food and medicine, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

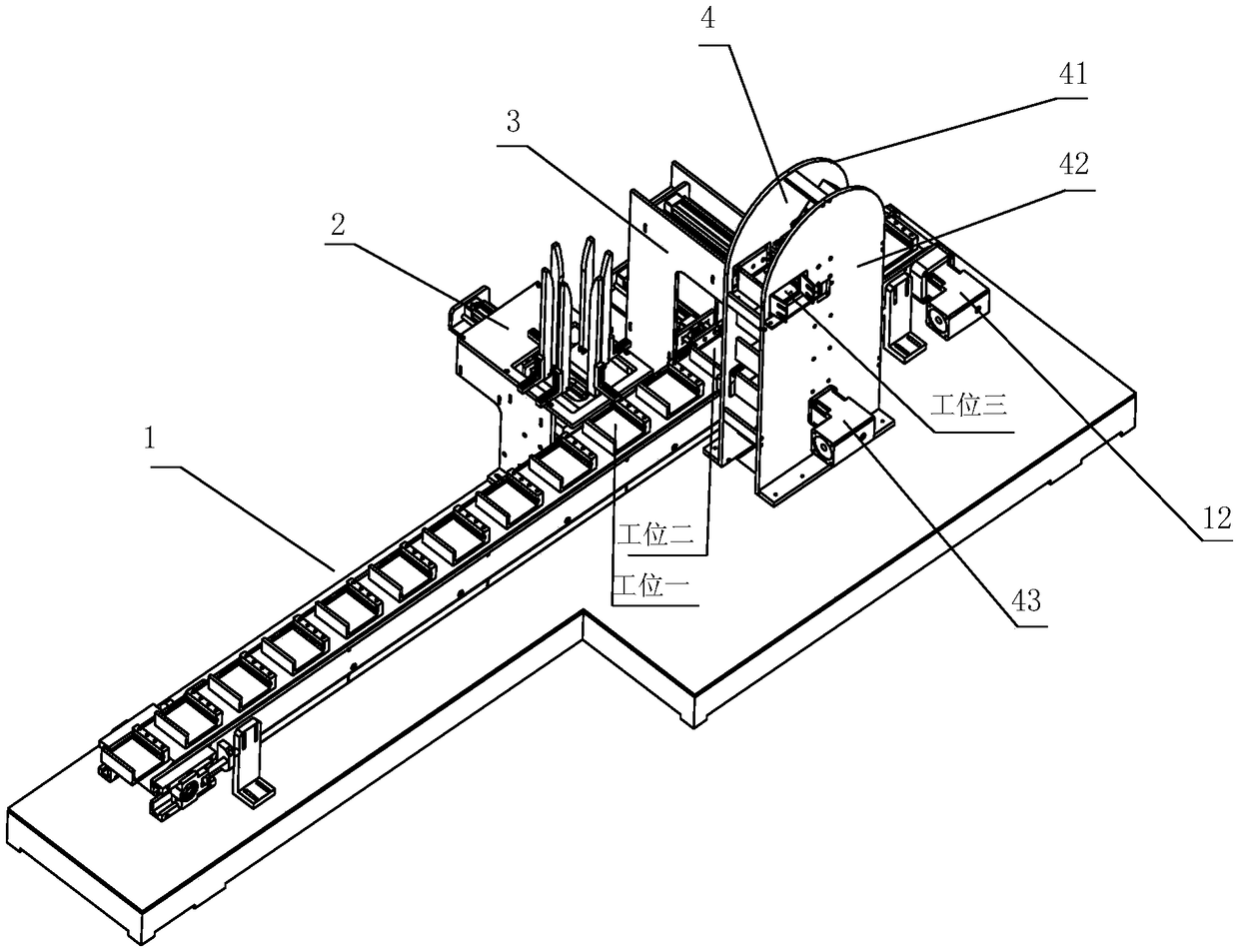

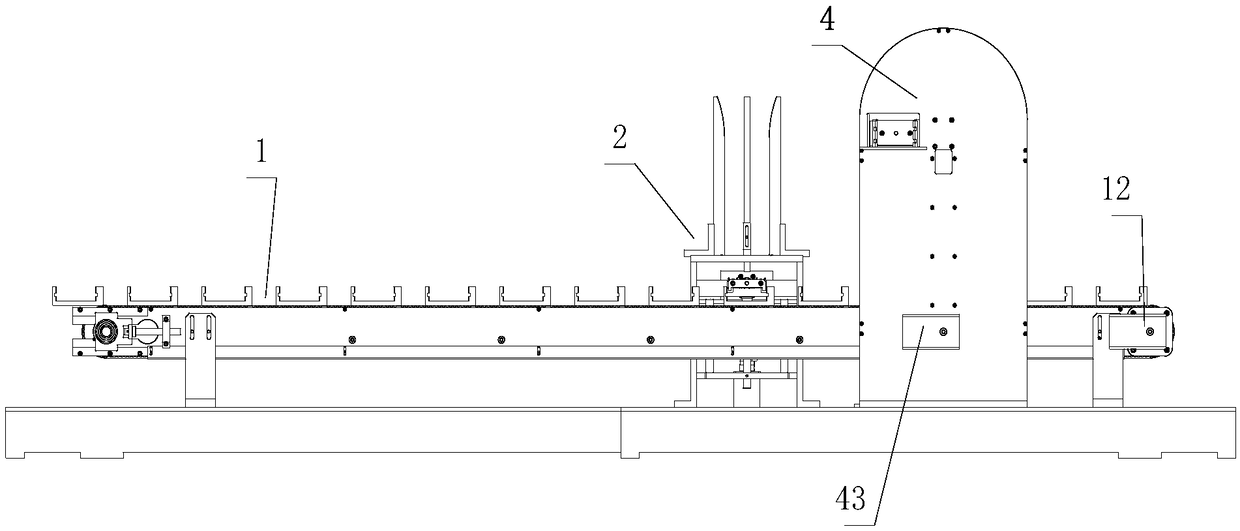

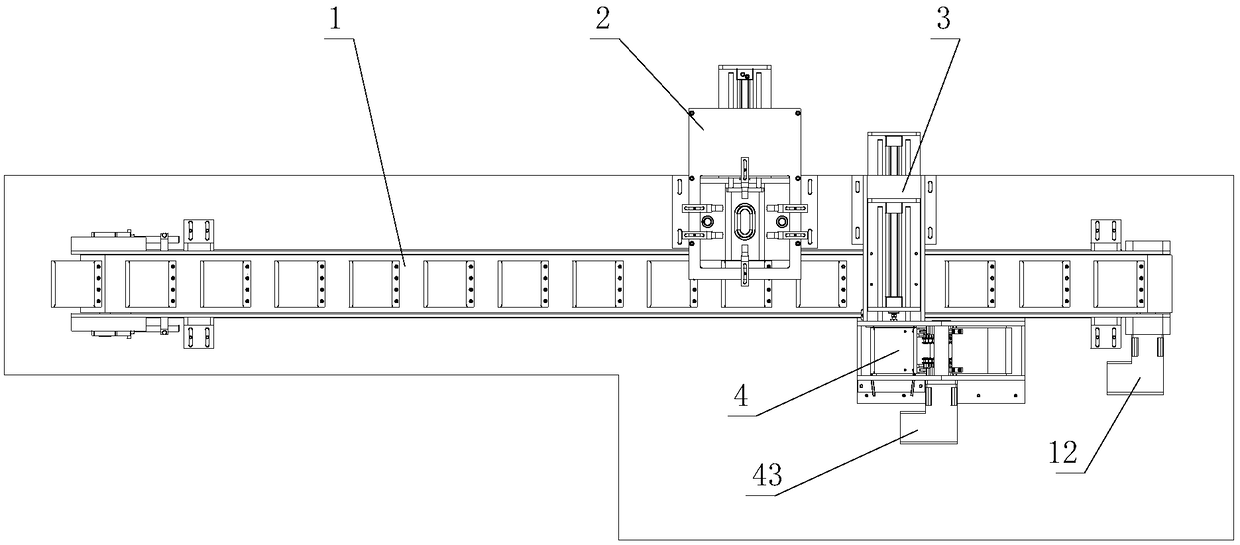

[0026] Such as figure 1 , figure 2 and image 3 As shown, the present invention proposes a double-layer stacking device for the packaging bag finishing production line of a multi-row packaging machine, including a support platform, on which a single-layer parts transmission mechanism 1, a cardboard placing mechanism 2, a pusher Bag mechanism 3 and lifting mechanism 4.

[0027] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, the single-layer part conveying mechanism 1 includes a single-layer packaging bag conveyor belt 11, and the single-layer packaging bag conveyor belt 11 is driven by a first servo motor 12, and a plurality of Single-layer packagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com