Permanent magnetoresistive speed reducer

A technology of reducer and permanent magnet, which is applied in the field of vehicle auxiliary braking devices, military vehicles and aircraft auxiliary braking, and can solve the problem of slow response time of hydraulic retarder manipulation, limited engine exhaust braking torque, engine Increase fuel consumption and other issues to achieve the effect of quick response, simple and convenient control, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

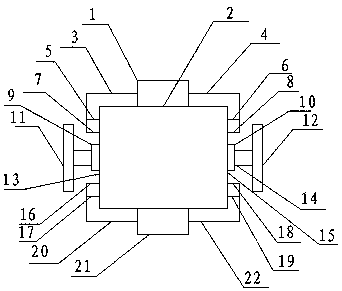

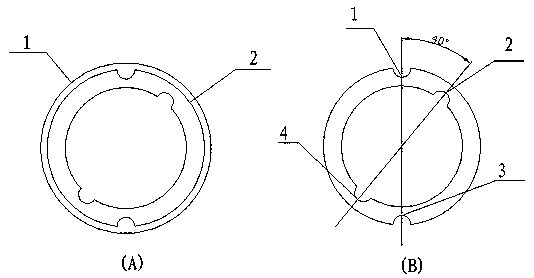

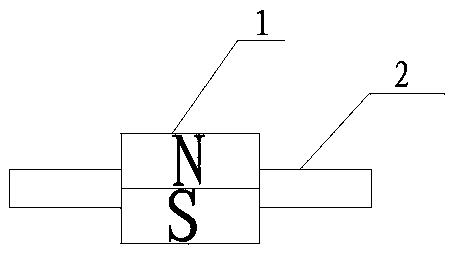

[0019] A permanent magnet reluctance reducer is composed of: a permanent magnet bipolar rotor, a stator, a rotor shaft, a bearing seat (including bearings), a main engine shell, a front end cover, a rear end cover, an upper magnetic guide rod, a lower magnetic guide rod, The upper two-way hydraulic valve, the lower two-way hydraulic valve, the upper push rod, the lower push rod, the input end flange, the output end flange, etc. The mutual position and assembly relationship are as follows: the permanent magnet bipolar magnet is assembled on the rotor shaft Composition of permanent magnet bipolar rotor assembly image 3 , the rotor shaft (14) is connected to the front end cover (13) and the rear end cover (15) respectively through the front bearing seat (9) and the rear bearing seat (10), and the front and rear end covers are respectively connected to the casing (2). figure 1 , see stator figure 2 , the stator is connected with the host shell (2), the upper two-way hydraulic v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com