Preparation method of fluoroquinolone antibiotic adsorbent

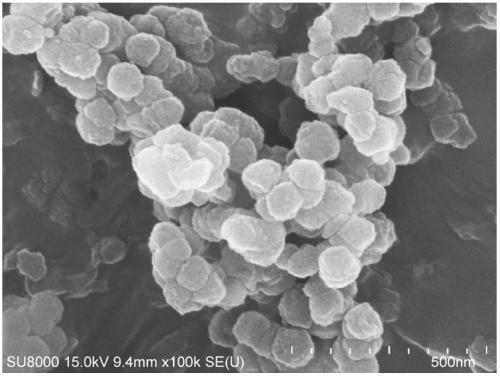

A technology of fluoroquinolones and quinolones, which is applied in the field of preparation of cobalt sulfate-UIO materials to remove fluoroquinolone antibiotics adsorbents, achieving the effects of large adsorption capacity, uniform particle size, and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of fluoroquinolone antibiotic adsorbent, comprising the following steps:

[0023] 1), according to the molar ratio of 1:1, zirconium tetrachloride and terephthalic acid were dissolved in 40mL of N,N-dimethylformamide to obtain A solution;

[0024] 2) Transfer solution A into a hydrothermal reactor, react at 120°C for 24 hours, cool to room temperature, centrifuge, wash, and dry at 80°C for 24 hours to obtain an intermediate product;

[0025] 3) Dissolve the intermediate product and cobalt sulfate in methanol at a mass ratio of 1:0.5 to obtain solution B, and magnetically stir solution B at 40°C for 1 hour;

[0026] 4) Cool to room temperature, centrifuge, and dry at 80°C for 24 hours to obtain the fluoroquinolone antibiotic adsorbent.

Embodiment 2

[0028] A preparation method of fluoroquinolone antibiotic adsorbent, comprising the following steps:

[0029] 1), according to the molar ratio of 1:2, zirconium tetrachloride and terephthalic acid were dissolved in 40mL of N,N-dimethylformamide to obtain A solution;

[0030] 2) Transfer solution A into a hydrothermal reactor, react at 120°C for 24 hours, cool to room temperature, centrifuge, wash, and dry at 80°C for 24 hours to obtain an intermediate product;

[0031] 3) Dissolve the intermediate product and cobalt sulfate in methanol at a mass ratio of 1:1 to obtain solution B, and magnetically stir solution B at 40°C for 1 hour;

[0032] 4) Cool to room temperature, centrifuge, and dry at 80°C for 24 hours to obtain the fluoroquinolone antibiotic adsorbent.

Embodiment 3

[0034] A preparation method of fluoroquinolone antibiotic adsorbent, comprising the following steps:

[0035] 1), according to the molar ratio of 1:3, zirconium tetrachloride and terephthalic acid were dissolved in 40mL of N,N-dimethylformamide to obtain A solution;

[0036] 2) Transfer solution A into a hydrothermal reactor, react at 120°C for 24 hours, cool to room temperature, centrifuge, wash, and dry at 80°C for 24 hours to obtain an intermediate product;

[0037] 3) Dissolve the intermediate product and cobalt sulfate in ethanol at a mass ratio of 1:0.8 to obtain solution B, and magnetically stir solution B at 25°C for 1 hour;

[0038] 4) Cool to room temperature, centrifuge, and dry at 60°C for 24 hours to obtain the fluoroquinolone antibiotic adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com