Building material mixing and stirring process

A technology for mixing and construction, which is applied in the direction of mixers, mixing methods, mixer accessories, etc., can solve the problems of inability to mix powder thoroughly, mixing dead corners of building materials, agglomeration, etc., and achieve faster mixing speed, faster crushing, and full mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

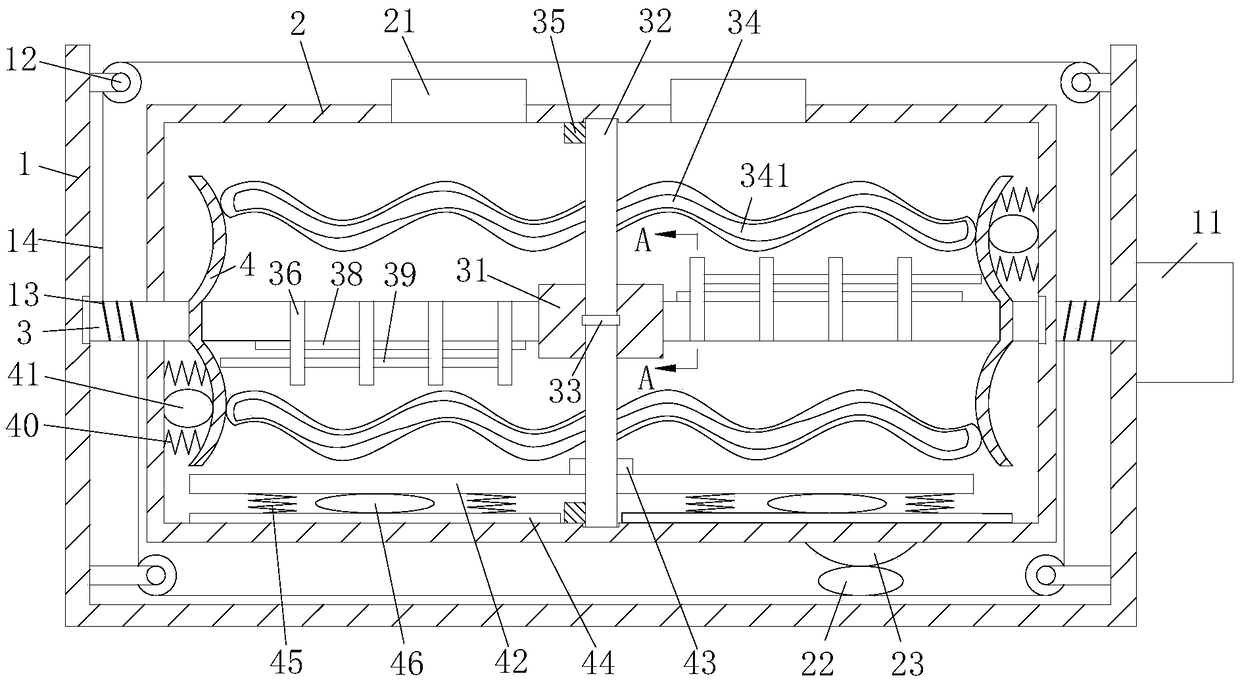

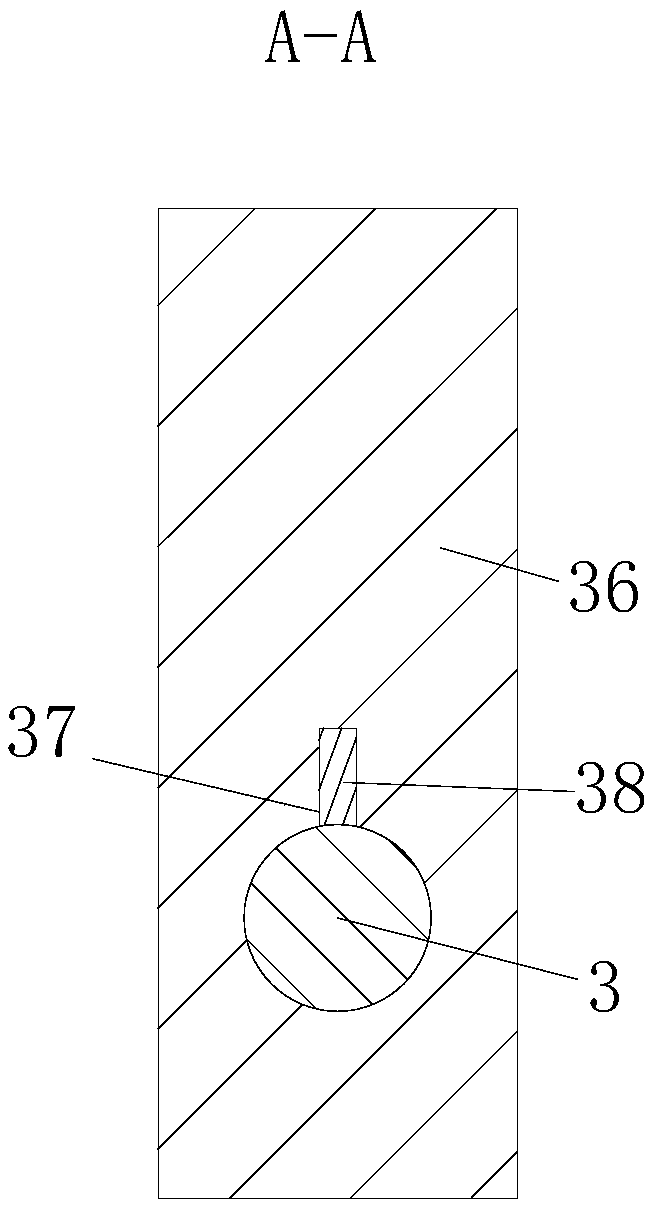

[0034] As an embodiment of the present invention, the surface of the driving shaft 3 on the left and right sides of the turning block 31 is provided with second stirring rods 36 evenly arranged; The surface of the shaft 3 is fixedly connected with an engaging plate 38 matching the engaging groove 37, and the second stirring rod 36 is slidably sleeved on the surface of the driving shaft 3 through the engaging groove 37, so that the driving shaft 3 can drive the second stirring rod 36 to rotate. At the same time, the second stirring rod 36 can slide on the surface of the driving shaft 3; when in use, the driving shaft 3 rotates, and the engagement of the engaging plate 38 in the engaging groove 37 drives the second stirring rod 36 to rotate, which can prevent the first stirring There is a stirring dead angle between the rods 34, which strengthens the stirring effect and makes the stirring more sufficient.

[0035] As an embodiment of the present invention, both ends of the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com