Kiwi fruit processing device and method

A processing device and kiwifruit technology, which are applied in juice extraction, food science, application, etc., can solve the problem of unable to simultaneously realize the separation of kiwifruit juice and pulp and peel when feeding kiwifruit raw materials, and achieve excellent technology, easy processing and manufacturing, and good continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

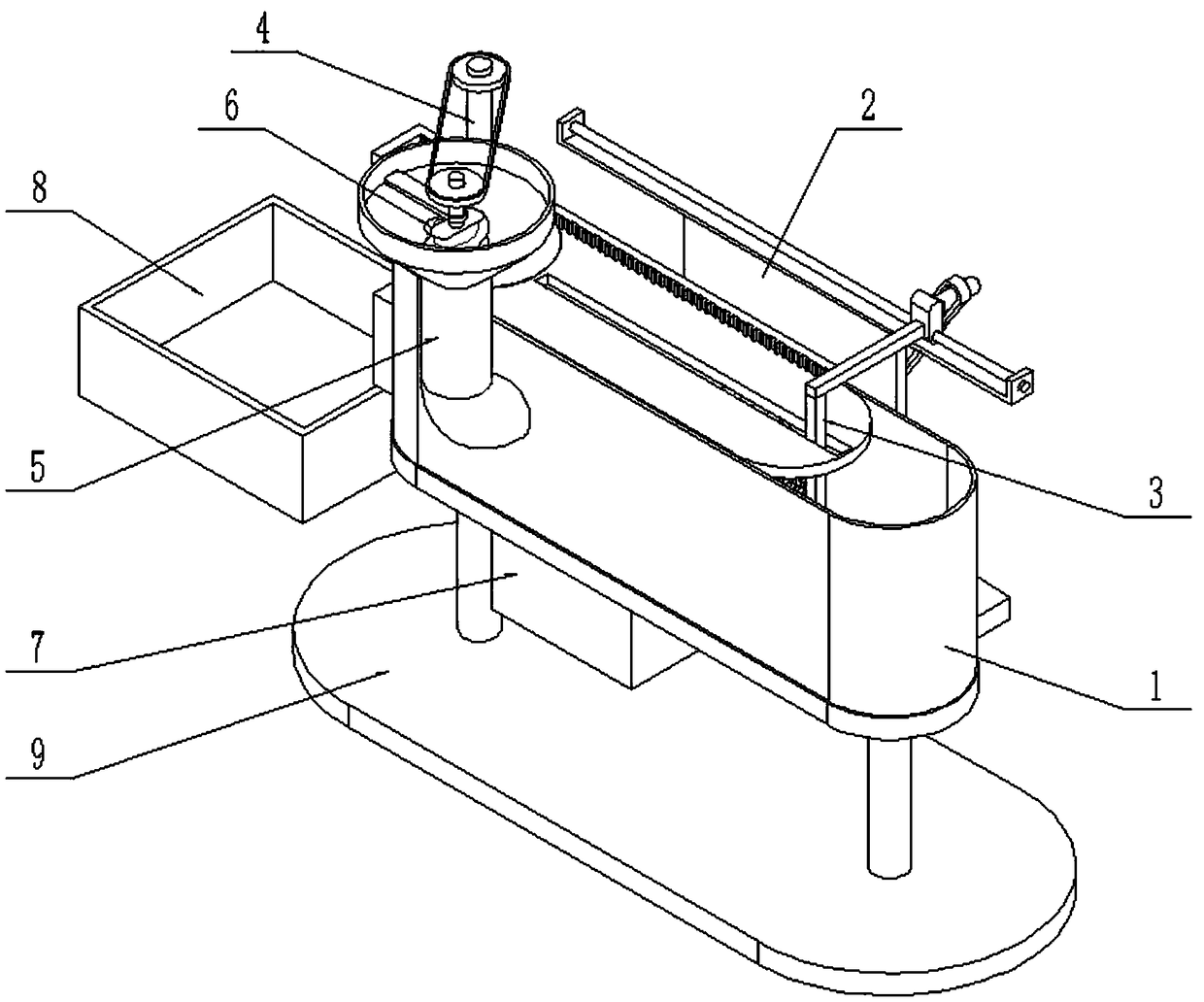

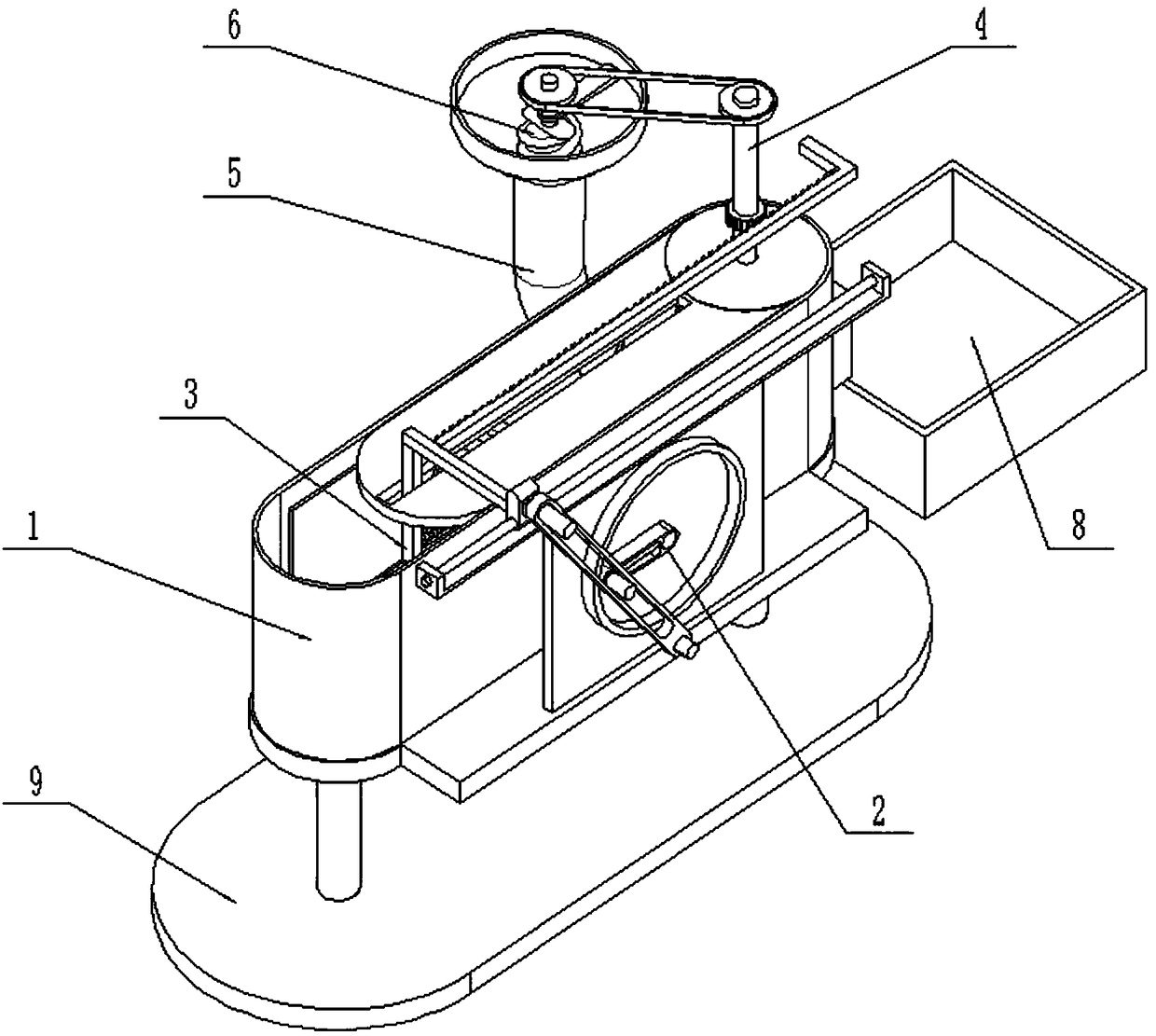

[0042] Such as Figure 1-13 As shown, a kiwi fruit processing device includes a crushing and separating box 1, a driving device 2, a reciprocating extrusion plate 3, a crushing knife wheel 4, a feed box 5, a primary crushing feeder 6, a juice collection box 7, and a pomace collection Box 8 and support base 9, the crushing and separation box 1 is fixedly connected to the support base 9; the driving device 2 is fixedly connected to the rear end of the crushing and separation box 1, and the driving device 2 is connected to the reciprocating extrusion plate 3 by transmission, and the reciprocating extrusion The pressing plate 3 is slidingly connected to the right end of the inside of the crushing and separating box 1; the crushing knife wheel 4 is connected to the left end of the inside of the crushing and separating box 1 in rotation; The material box 5 is fixedly connected to the front end of the crushing and separating box 1, and the feeding box 5 is located between the crushin...

specific Embodiment approach 2

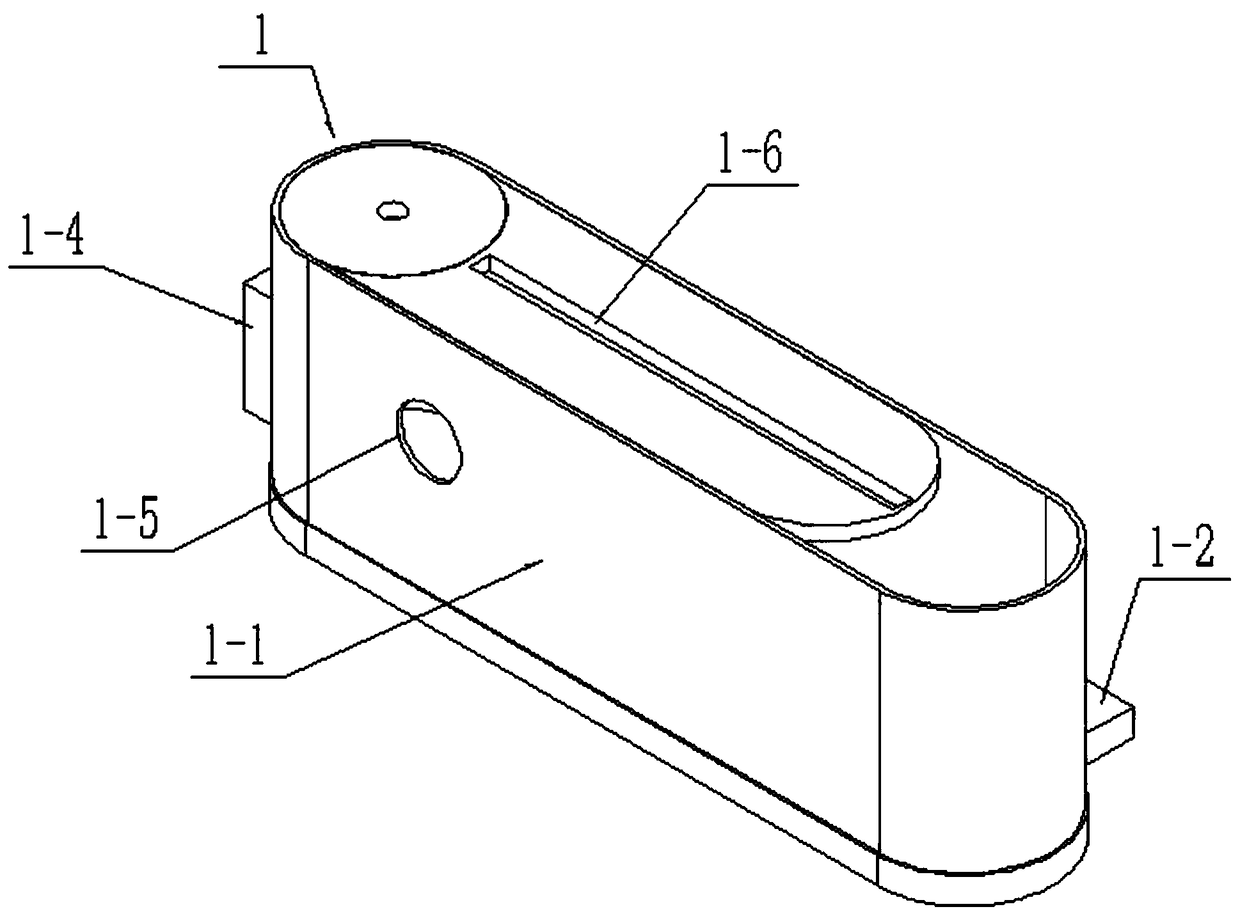

[0044] Such as Figure 1-13 As shown, the crushing and separating box 1 includes a box body 1-1, a horizontal plate 1-2, a filter plate 1-3, a slag outlet 1-4, a feed port 1-5 and a horizontal sliding hole 1-6; The rear end of the box body 1-1 is fixedly connected to the horizontal plate 1-2; the left end of the box body 1-1 is provided with a slag outlet 1-4, and the slag outlet 1-4 is used to discharge the residual after extrusion and crushing. Fruit peel and pomace, fruit peel and pomace can enter the inside of pomace collection box 8 through slag outlet 1-4 to collect and utilize, and the front end of box body 1-1 is provided with feed inlet 1-5, and feed inlet 1 -5 is used to import the kiwifruit raw material inside the feed box 5 into the inside of the casing 1-1; the top surface of the casing 1-1 is provided with a horizontal sliding hole 1-6; the bottom surface of the casing 1-1 There is a rectangular through hole on the top, and the inner side of the rectangular thro...

specific Embodiment approach 3

[0045] Such as Figure 1-13 As shown, the drive device 2 includes a servo motor 2-1, a drive shaft 2-2, a motor base 2-3, a vertical frame plate 2-4, a door frame 2-5, a guide shaft 2-6, and a horizontal slider 2-7, sliding shaft 2-8, rotating arm 2-9, linkage shaft 2-10, fixed shaft 2-11 and push-pull frame 2-12; the servo motor 2-1 is fixedly connected to the On the front side of the vertical frame plate 2-4, the lower end of the vertical frame plate 2-4 is fixedly connected to the horizontal plate 1-2; the output shaft of the servo motor 2-1 is connected to the drive shaft 2-2 through a coupling; The middle end of the drive shaft 2-2 is rotatably connected to the center of the vertical frame plate 2-4 through a bearing with seat, and the rear end of the drive shaft 2-2 is fixedly connected to one end of the rotating arm 2-9, and the rotating arm 2- The other end of 9 is fixedly connected to the linkage shaft 2-10; the top of the vertical frame plate 2-4 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com