Automatic feeding system for track type indoor breeding feeders

A feeding machine and track-type technology, applied in the field of aquaculture feeding, can solve the problems of affecting the normal growth of fish, low degree of automation, fish stress response, etc., and achieve reduced labor intensity, high degree of automation, and reduced frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

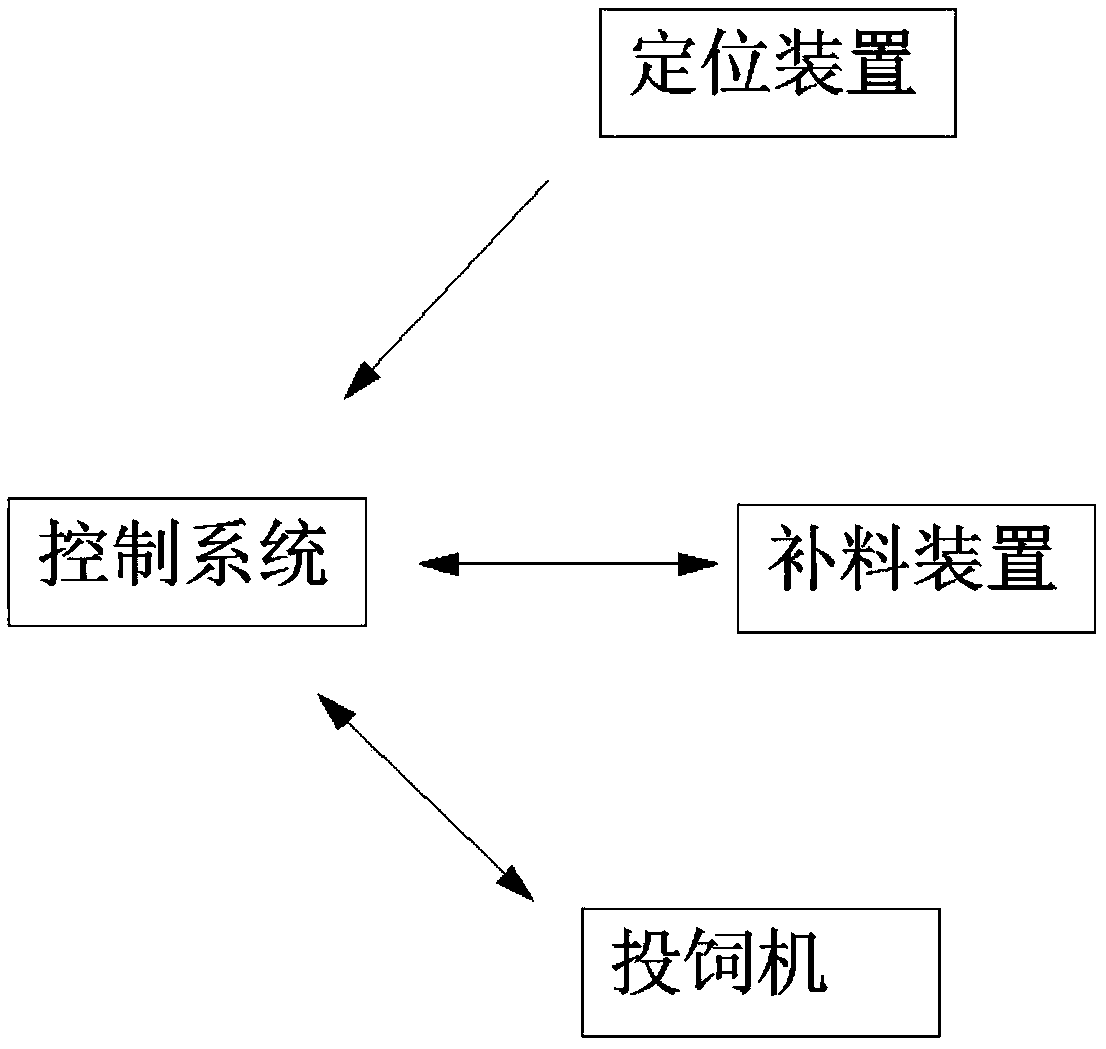

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

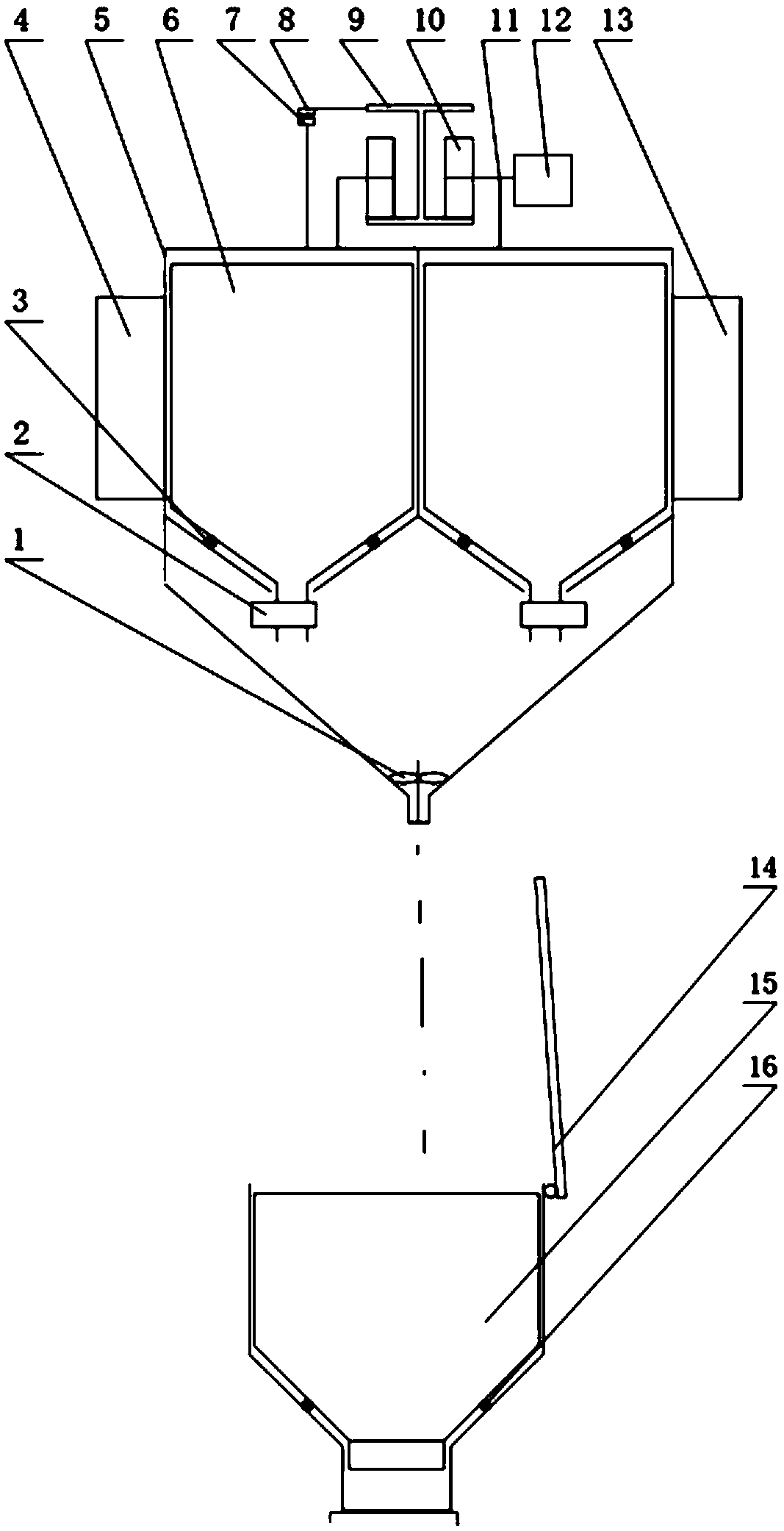

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

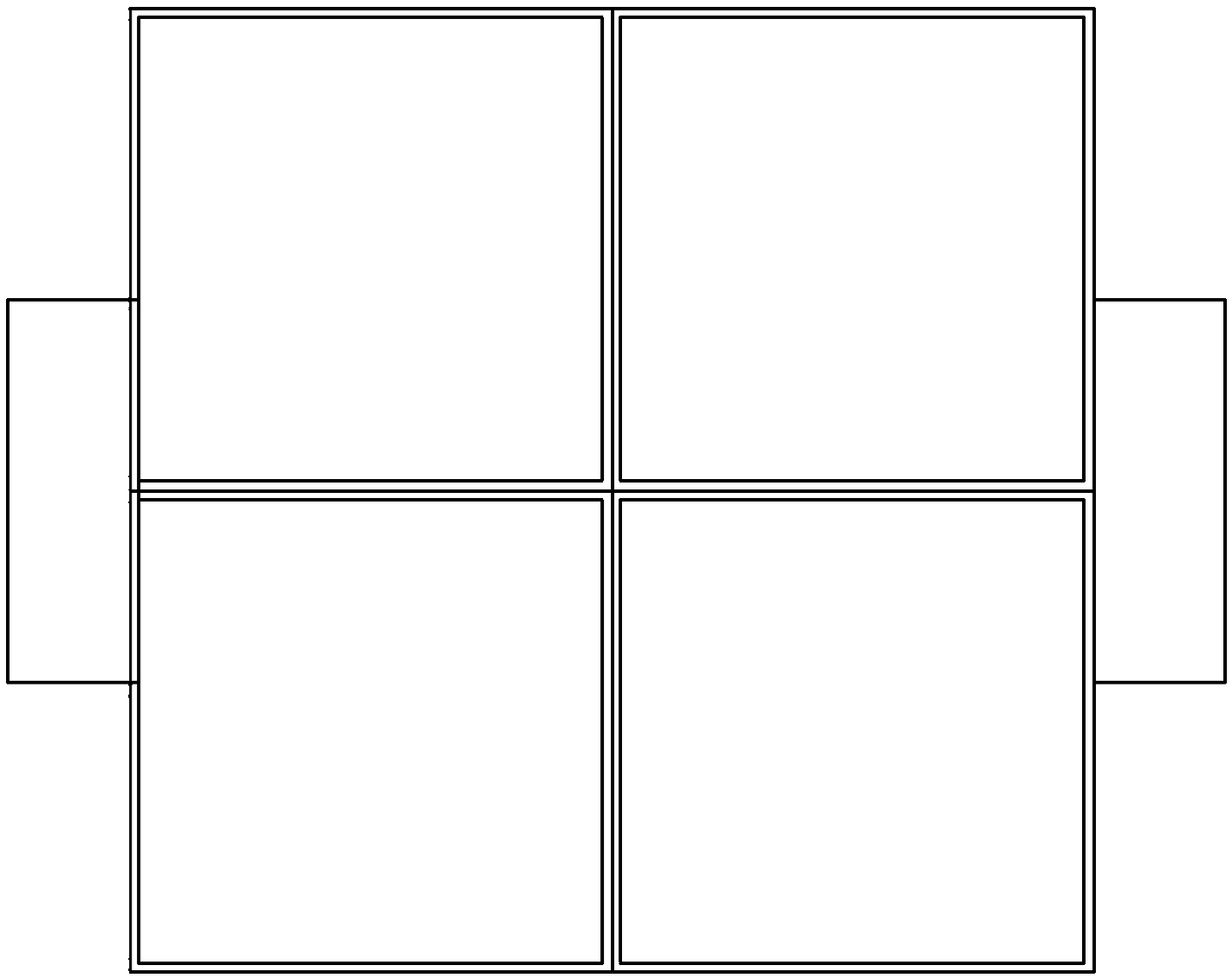

[0027] see Figure 1-3 , Install the guide rail 9 on the top of the workshop, the position of the guide rail 9 ensures that the outlet of the feeding device is directly above the feeding machine silo.

[0028] DC motor 12 is installed on the track by transmission wheel, and feeding device is connected with motor by mechanical structure; Transmission wheel 10 uses rubber wheel, to reduce the sound during motion, affects fish growth; Motor has braking device.

[0029] This device adopts storage battery 4 to supply power.

[0030] The feeding device is composed of silos 6 and a feeding mechanism. There are 4 silos, which are used to place one or more kinds of feed; an electric valve 2 is installed at the outlet of each silo to control the discharge; each The silo 6 has an independent silo weight sensor 3, which is used to automatically return to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com