A kind of production method of deer glue and rubber mixing device

A rubber mixing device and deer rubber technology, which is applied in the direction of measuring device, test sample preparation, material excitation analysis, etc., to achieve scientific, repeatable and stable refining process of deer rubber

Active Publication Date: 2019-10-01

山东东阿一品堂阿胶生物有限公司

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although it adopts industrial production, it is only for further processing after the deer gum is refined, and does not fundamentally change the production method of deer gum

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Login to View More

Abstract

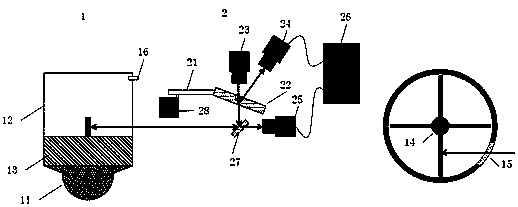

The invention relates to the field of optical detection and Chinese medicine preparation, relates to the preparation process of the deer antler glue, and specially relates to a preparing device and amethod for the deer antler glue based on the detection of Raman spectroscopy and infrared spectroscopy. The invention provides a refining device for deer antler glue. The preparing method comprises the following steps: heating and refining the deer antler glue in a heating kettle; performing a Raman spectra analysis and an infrared spectra analysis on the refined deer antler glue by using a lightdetecting unit. The preparing method and the refining device for the deer antler glue adopt the Raman spectroscopy to analyze the changes of ingredients in the refining process of the deer antler glue, and adopt the infrared spectroscopy to analyze the changes of moisture content in the refining process of the deer antler glue, so that the detection precise is higher, the refining process of the deer antler glue is scientific and reproducible, and the instability of artificial boiling is avoided. The preparing method and the refining device for the deer antler glue are ingeniously provided with a device for simultaneously detecting the Raman spectroscopy and the infrared spectroscopy by using one light source, which is suitable for the refining of the deer antler glue and can detect the deer antler glue during different time periods. The refining device can simulate the stirring and the scraping of the artificial deer antler glue, and can more stably and uniformly refine.

Description

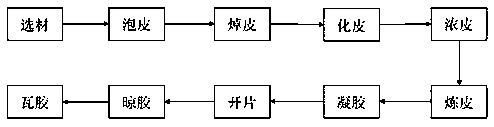

technical field The invention relates to the field of optical detection of traditional Chinese medicine production, relates to a production process of deer glue, and in particular to a device and method for making deer glue using Raman spectrum and infrared spectrum detection. Background technique The production process of deer glue basically follows the ancient method. Because of the nine important processes, each process requires nine steps, also known as the "nine-nine glue boiling method". As a national intangible cultural heritage, deer glue production skills have been explored and formed a unique set of techniques after more than two thousand years of practice, which are mainly divided into raw material processing, juice extraction and decoction, concentrated gel collection, gel cutting, drying, There are 49 processes such as rubber wiping and packaging, nine key processes, each process requires nine major steps, and a total of 998 processes can be completed. The glue m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N1/28G01N1/30G01N1/40G01N21/3563G01N21/65

Inventor 李明山

Owner 山东东阿一品堂阿胶生物有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com