Novel setaria viridis fireworks forming process

A molding process, the technology of foxtail grass, which is applied in the directions of fireworks, weapon types, offensive equipment, etc., can solve the problems affecting the overall quality of products, uneven packaging, poor product integrity, etc., to achieve good packaging effects, convenient operation, and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

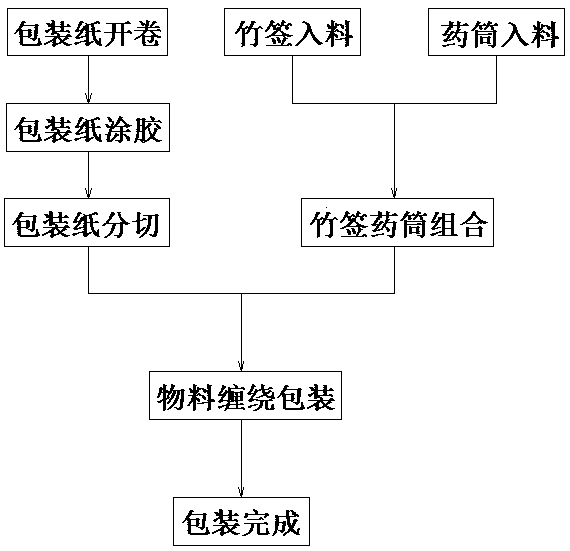

[0021] figure 1 A preferred embodiment of the present invention is shown, its composition, unwinding 1, gluing 2, cutting 3, bamboo stick 4, cartridge 5, combination 6, wrapping 7.

[0022] The structural features of specific embodiments of the present invention are:

[0023] A new-type foxtail firework molding process, mainly used for the molding of foxtail fireworks in paper continuous gluing, slitting, high-speed winding packaging equipment, characterized in that it includes unwinding wrapping paper, gluing, wrapping paper cutting, bamboo stick feeding, Cartridge feeding, combination of bamboo sticks and cartridges, winding packaging, specifically include the following steps:

[0024] Step 1: Unwind the wrapping paper, and provide the wrapping paper by continuously unwinding the whole roll of wrapping paper;

[0025] Step 2: Glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com