Washing machine

A washing machine and washing tub technology, applied in the field of washing machines, can solve the problems of increased inner tub vibration, large volume, damage to motors, etc., and achieve the effects of reducing usage, improving utilization rate, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

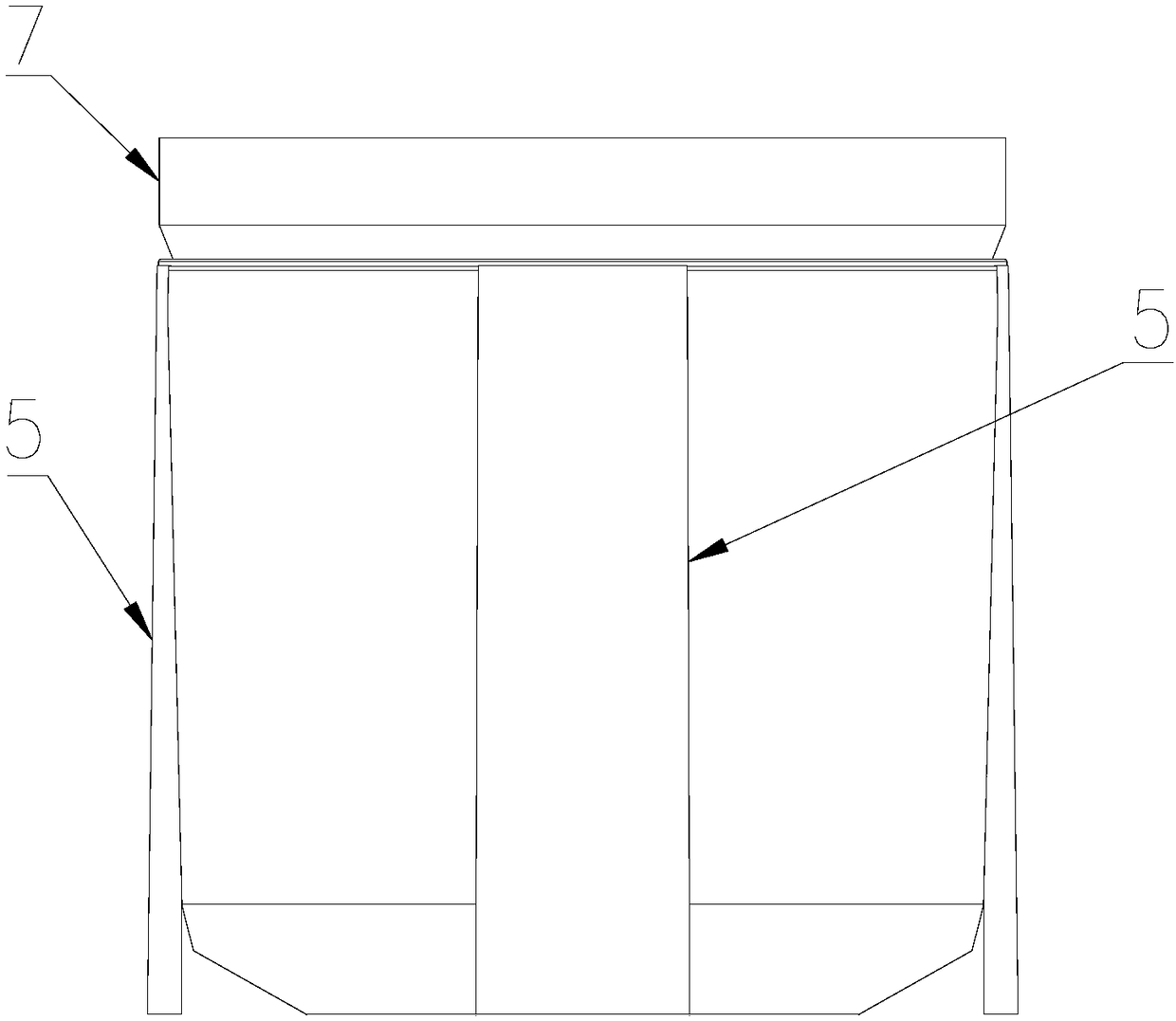

[0029] Such as Figure 1 to Figure 4 As shown, a washing machine includes a box body 1, a washing tub 2 for accommodating laundry to be washed, a power unit 3 for driving the washing tub 2 to rotate, a mounting plate 4 installed at the bottom of the washing tub 2, and a connecting mounting plate 4 Vibration-absorbing parts with box 1. The washing bucket 2 is rotatably arranged in the box body 1. The washing bucket 2 is located on the mounting plate 4 and can rotate relative to the mounting plate 4. The washing bucket 2 is used as a bucket for containing washing water, and the mounting plate 4 is used for The washing bucket 2 is supported, and the mounting plate 4 is movably connected with the box body 1 through the damping component. When washing or dehydrating, the washing bucket 2 and the mounting plate 4 will vibrate, and the vibration will be absorbed after being transmitted to the damping component.

[0030] A water retaining ring 13 is provided on the mounting plate 4, ...

Embodiment 2

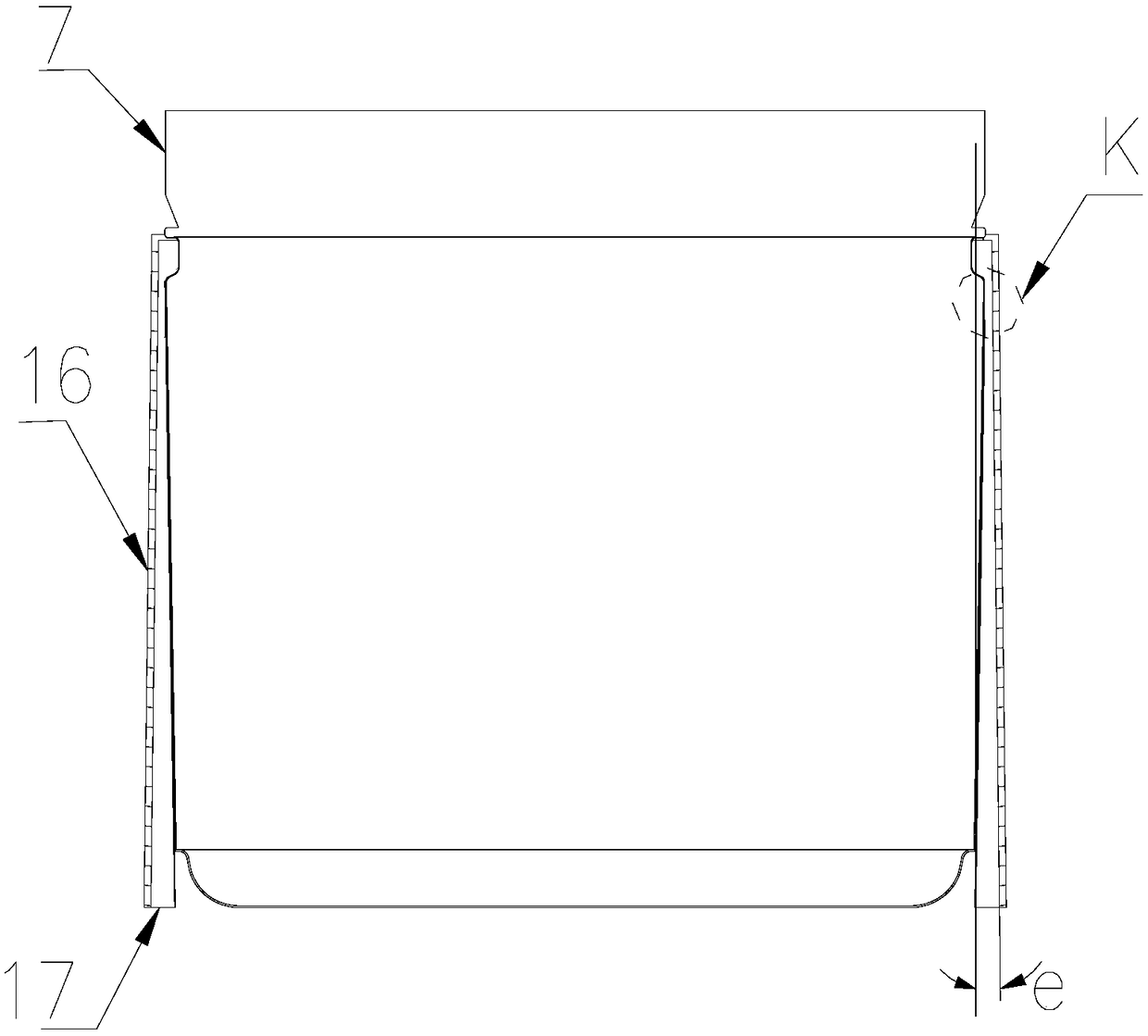

[0044] Such as Figure 5 to Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the upper end of the washing bucket 2 is also provided with a water collection ring 11, and the inner side of the water collection ring 11 is provided with a dehydration hole 8 communicating with the washing bucket 2. The upper end of the channel 5 communicates with the water collecting ring 11 , and the lower end communicates with the inner drain provided at the bottom of the washing tub 2 .

[0045] The inner diameter of the washing bucket 2 gradually increases from bottom to top. When the washing bucket 2 rotates at a high speed, the washing water in the washing bucket 2 will climb upwards along the wall of the washing bucket under the action of centrifugal force, and after rising to a certain height, Enter in the water collection ring 11 from the dewatering hole 8 of the water collection ring 11, the volume of the water collection ring 11 is relatively small, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com