A manufacturing process of an automobile decorative part and an automobile decorative part

A technology of automobile decoration and manufacturing technology, which is applied in the field of machinery, can solve the problems of affecting the appearance and large matching gaps of decorative parts, etc., and achieve the effect of preventing scratches and good friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

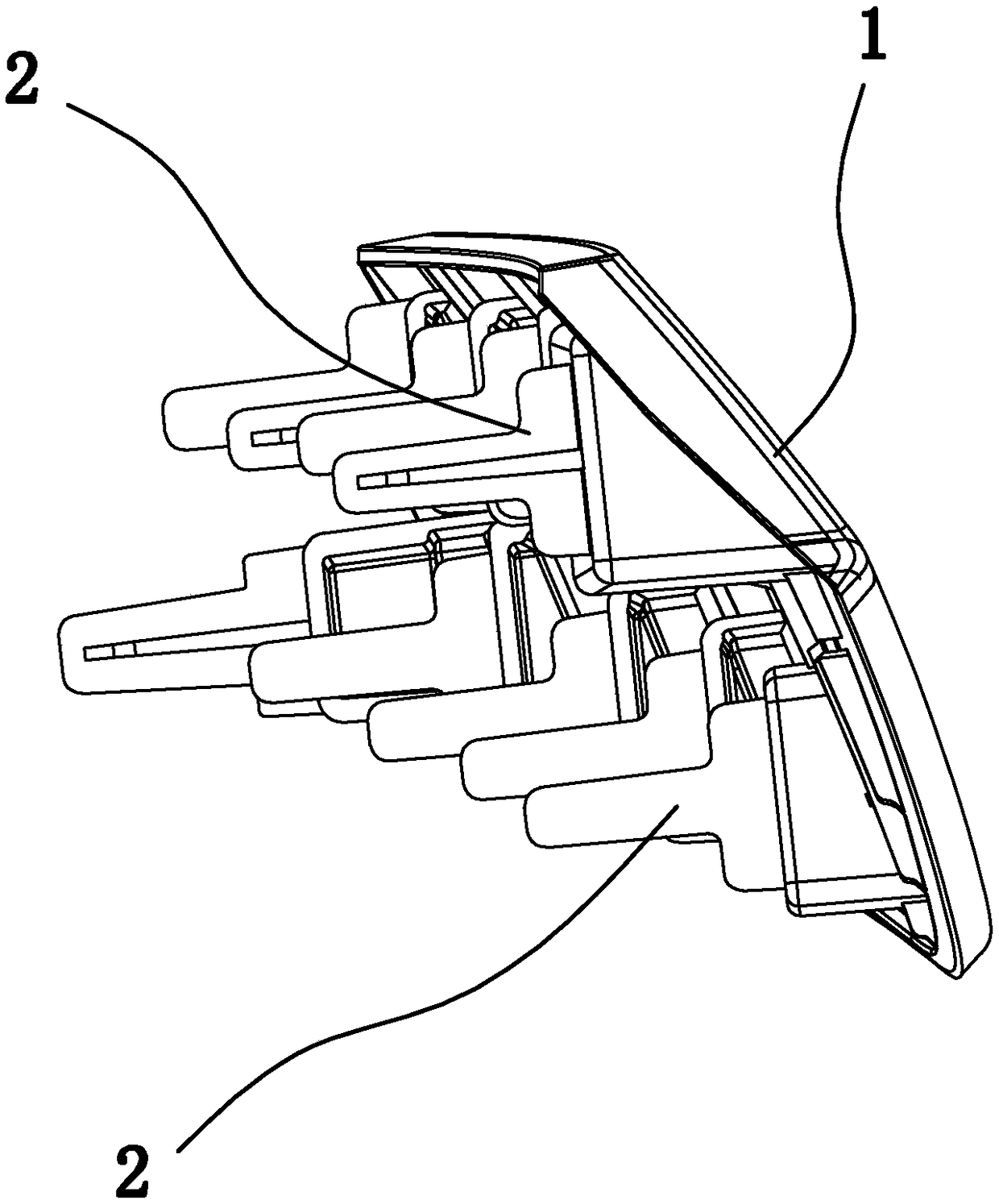

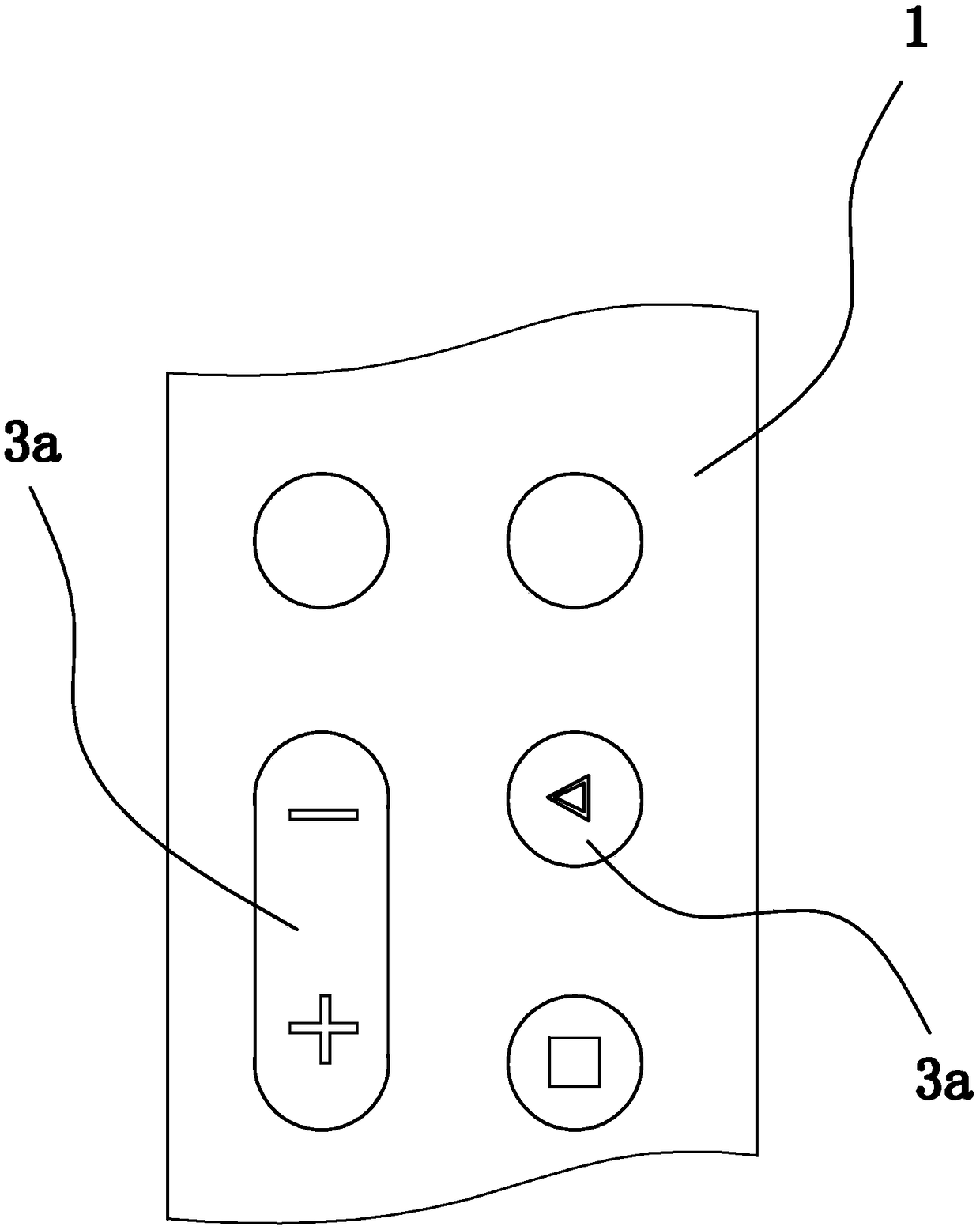

[0031] Such as figure 1 , 4 As shown in and 5, the automotive trim includes a decorative panel 1 made of real wood, a number of skeletons 2 made of transparent materials, and a number of diaphragms 3 with touch patterns 3a. The decorative panel 1 is in the shape of a sheet, and the skeleton 2 has an installation surface, and the touch pattern 3 a is compounded on the installation surface through the diaphragm 3 . A touch sensor 4 corresponding to the touch pattern 3 a is provided on the back of the frame 2 opposite to the installation surface, and a light source 5 capable of projecting the touch pattern 3 a onto the decorative panel 1 is provided on the frame 2 .

[0032] Specifically, the thickness of the decorative panel 1 is 0.5-0.8 mm. The skeleton 2 is made of transparent PC material, and the skeleton 2 is pressed and fixed on the back of the decorative panel 1 .

[0033] The car trim is made by the following methods:

[0034] Step a, select a real wood veneer of 0.5-...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, the difference is that: the back of the decorative panel 1 also has a non-woven fabric layer, and the non-woven fabric layer is bonded to the back of the decorative panel 1 by transparent hot-melt paper.

[0039] This real wood trim piece is made by:

[0040] Step a. Choose a real wood veneer of 0.5-0.8mm, glue a light-transmitting non-woven fabric with a thickness of 0.5-1.5mm on the back of the real wood veneer through transparent hot-melt paper, and then pre-press the real wood veneer to form a decorative panel. In this embodiment, a 0.5mm real wood sheet and a 0.5mm light-transmitting non-woven fabric are selected.

[0041] Step b. Select a number of skeletons 2 made of transparent PC material and a number of diaphragms 3. The diaphragm 3 is made of acrylic material and has a touch pattern 3a formed on it after graphic printing, and then passes the diaphragm 3 through INS or IMD. The process is compounded on th...

Embodiment 3

[0043] Such as Image 6 As shown, the car decoration includes a decorative panel 1 made of light-transmitting fabric or thick imitation suede material and a skeleton 2 made of transparent material. The decorative panel 1 is in the shape of a sheet, and the decorative panel 1 is covered on the skeleton 2 or through low-pressure injection molding and fixed to the frame 2, the frame 2 is fixed on the back of the decorative panel 1 and the frame 2 is fixed with a light guide strip or a diaphragm 3 with a pattern printed on it, and the frame 2 is provided with a pattern that can project the pattern to the light source 5 on the decorative panel 1.

[0044] The car trim is made through the following steps:

[0045] Step a: Use light-transmitting fabric and thick imitation suede to form a thin sheet-shaped and light-transmitting decorative panel 1 with a thickness of 0.5-0.8mm, which is made of a mixed material of PC and glass fiber or PA6 light-transmitting material Skeleton 2, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com