Electric power construction safety supervision robot

A technology of electric power construction and robotics, which is applied to manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of time-consuming and labor-intensive monitoring, ineffective monitoring, etc., and achieve the effects of wide monitoring range, accidental collision prevention, and good monitoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

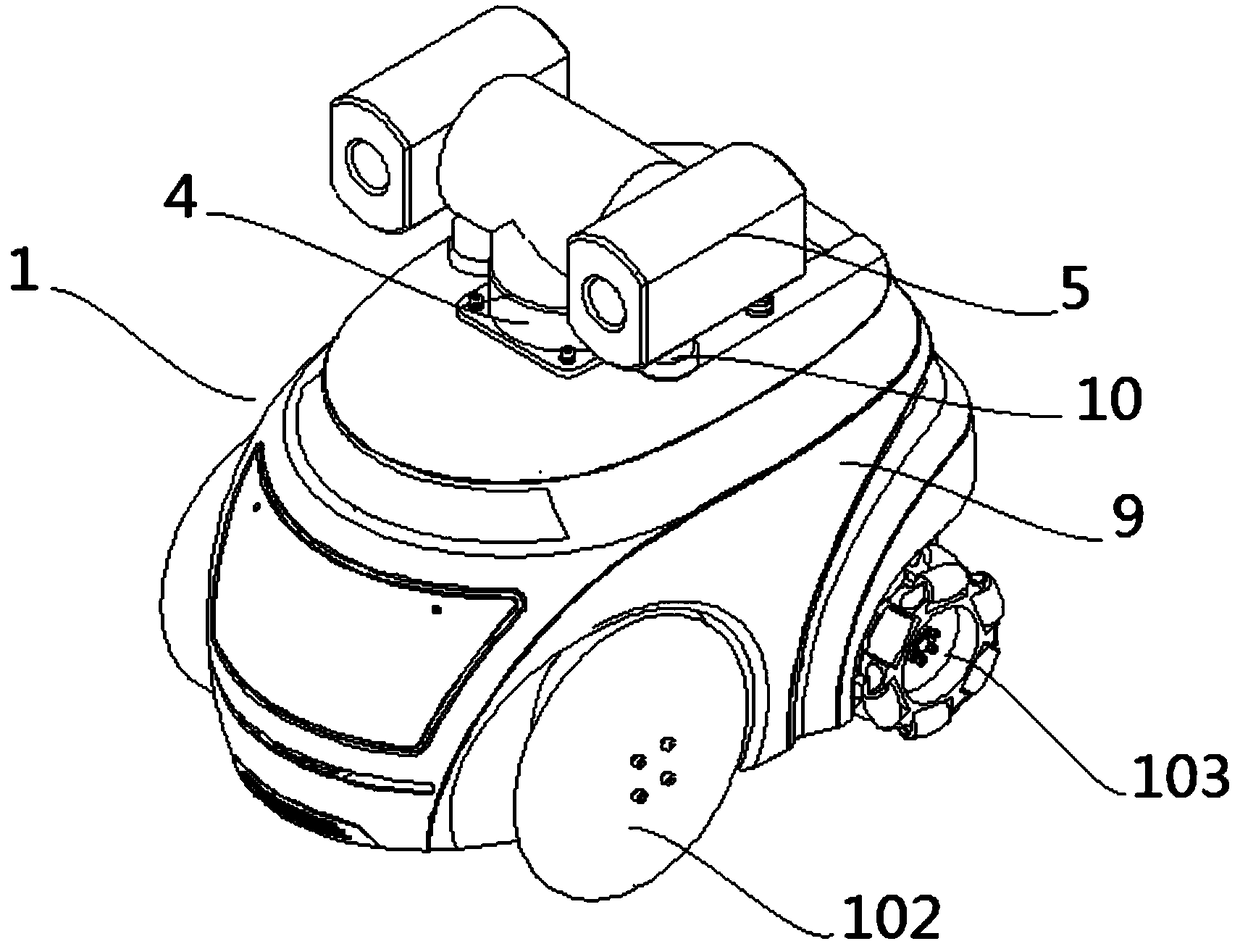

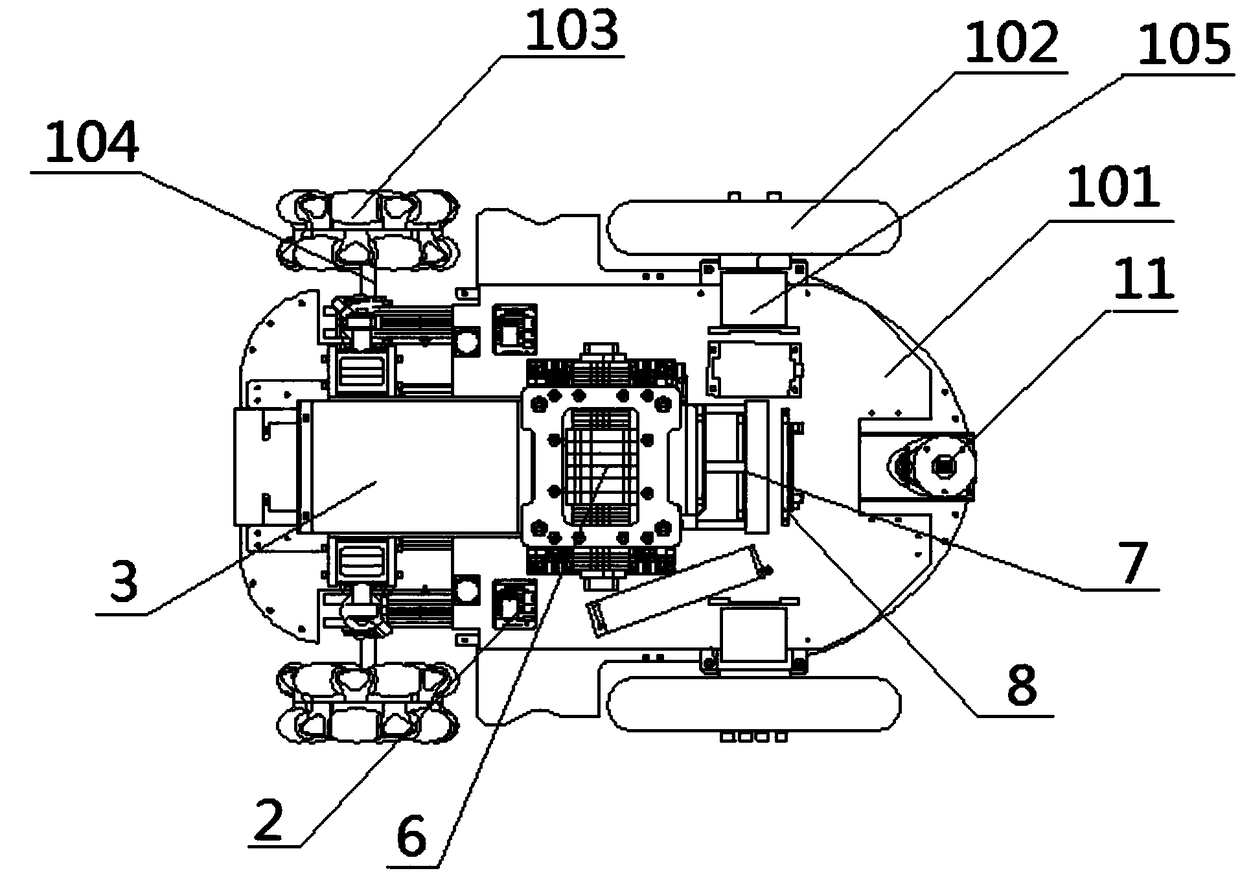

[0024] Such as figure 1 and figure 2 As shown, an electric power construction safety supervision robot of the present invention includes a robot body 1 on which a driving motor 2, a power supply 3, a pan-tilt 4 and an information collection unit are arranged. Robot body 1 comprises chassis 101, front wheel 102, rear wheel 103, rear axle 104 and front axle 105; The output end of is connected with front axle 105, and front axle 105 is connected with rear axle 104 through transmission. The transmission device comprises a driving wheel, a driven wheel and a chain; the driving wheel is arranged on the front axle 105, the driven wheel is arranged on the rear axle 104, and the chain is sleeved on the driving wheel and the driven wheel to realize the four-wheel drive transmission of the robot and improve the performance of the robot. Obstacle surmountability. The drive motor 2 is electrically connected to a power supply 3, which is preferably but not limited to a secondary lithium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com