A washing and absorbing device for preparing electronic-grade hydrogen fluoride

An absorption device, hydrogen fluoride technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as safety accidents, non-compliance with technical specifications, increased difficulty and cost of treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

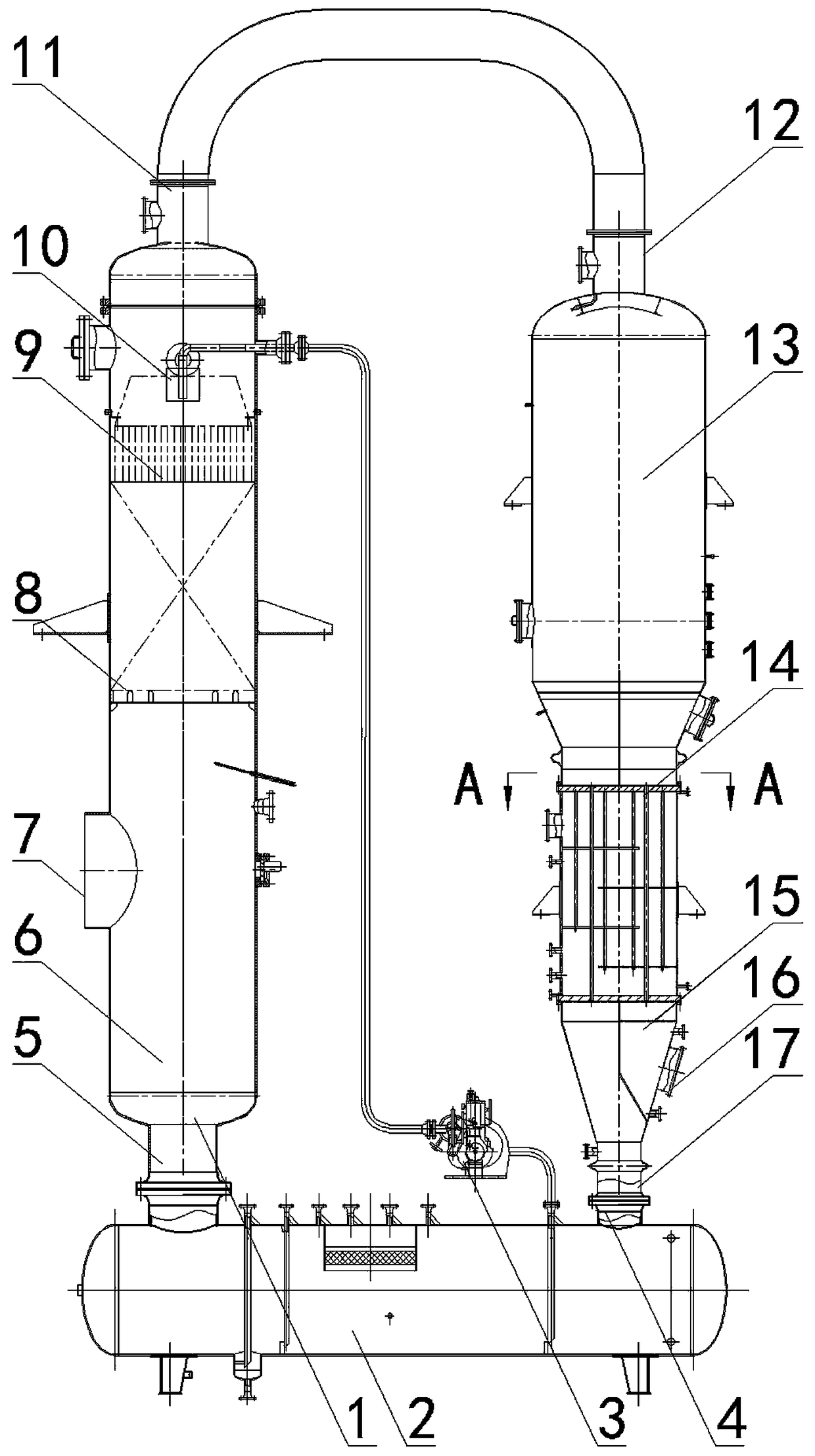

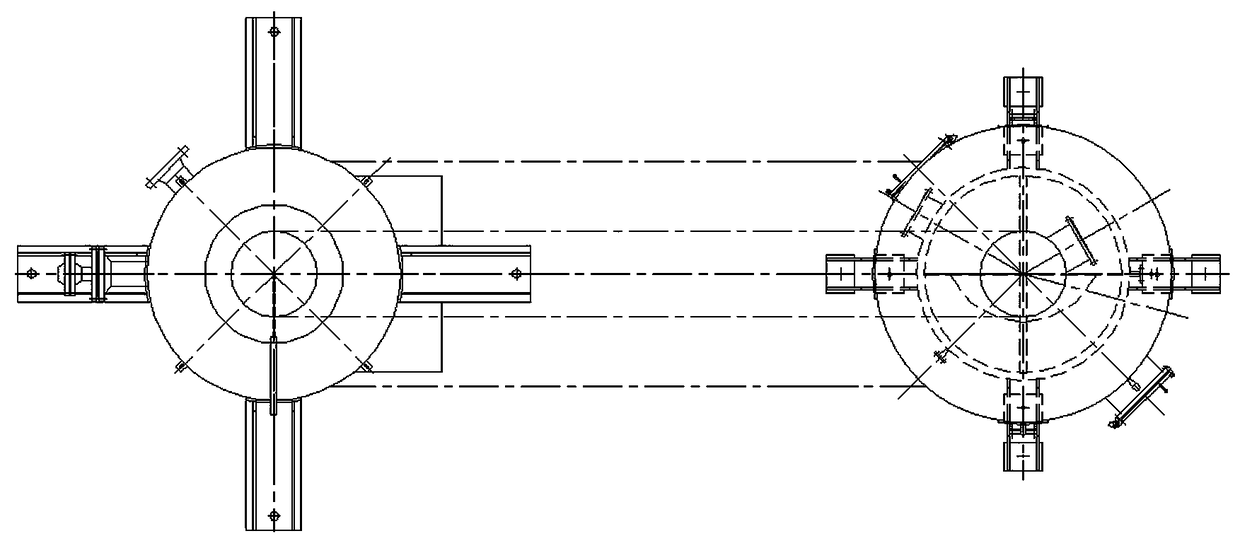

[0021] like figure 1 , figure 2 , image 3 As shown, a washing and absorbing device for preparing electronic-grade hydrogen fluoride is characterized in that it includes a washing and absorbing tower 1, a circulating storage tank 2, a circulating pump assembly 3, a condensation tower 4, the bottom of the washing and absorbing tower 1, the condensing tower 4 and the circulating storage The slots 2 communicate to form a U-shaped connector.

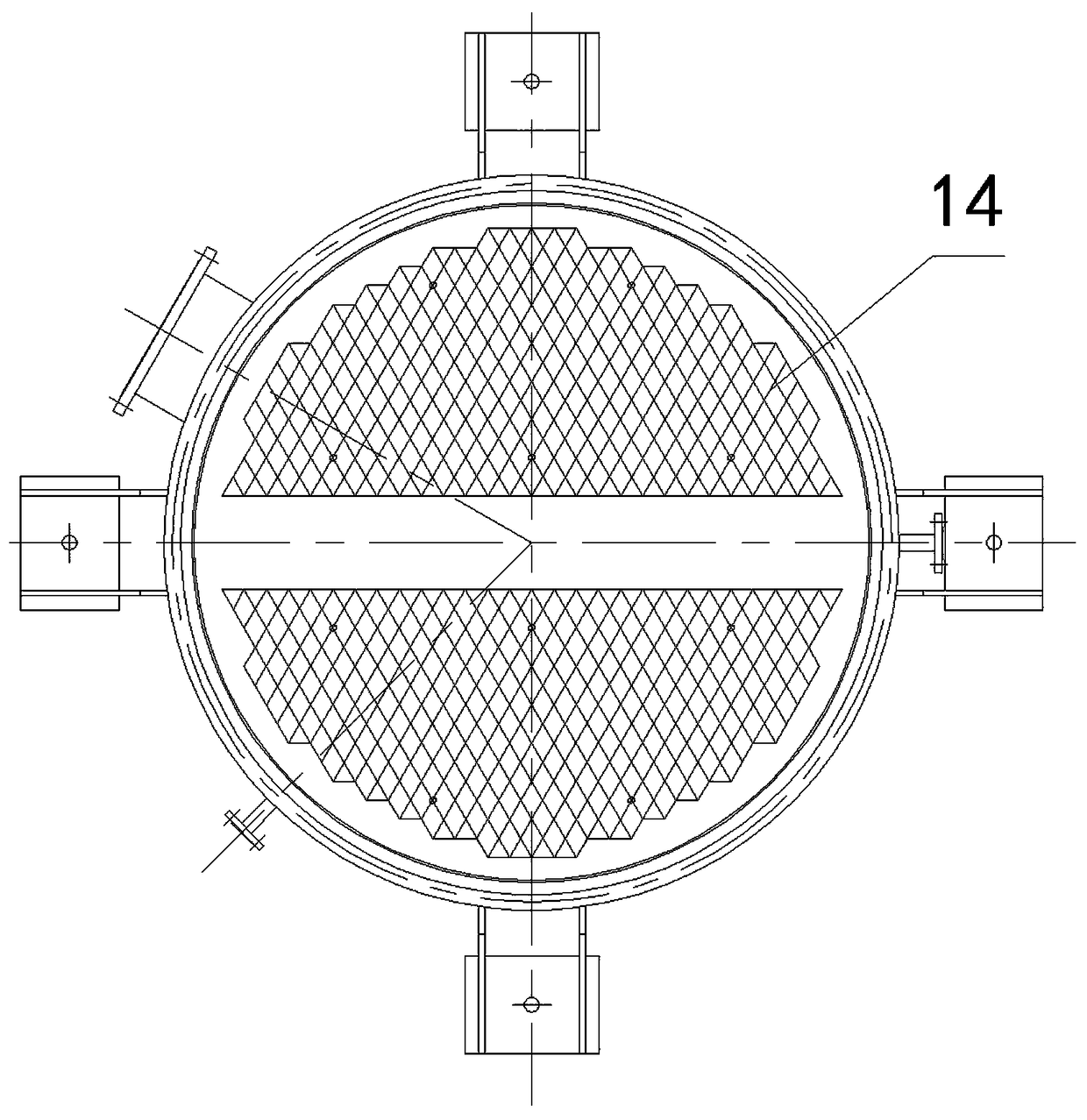

[0022] The washing and absorbing tower 1 includes a liquid collecting pipe 5, a washing and absorbing tower body 6, an air inlet duct 7, a packing 8, a liquid distribution grid 9, a spray pipe fitting 10, and an exhaust duct 11. The condensation tower 4 includes an exhaust gas inlet 12. Condensing tower body 13, condensing tube plate 14, liquid removal device 15, tail gas discharge port 16, condensate out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com