Palm leaf extract and application thereof

A kind of technology of leaf extract and palm tree, which is applied in the application field of preparing antidepressant drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

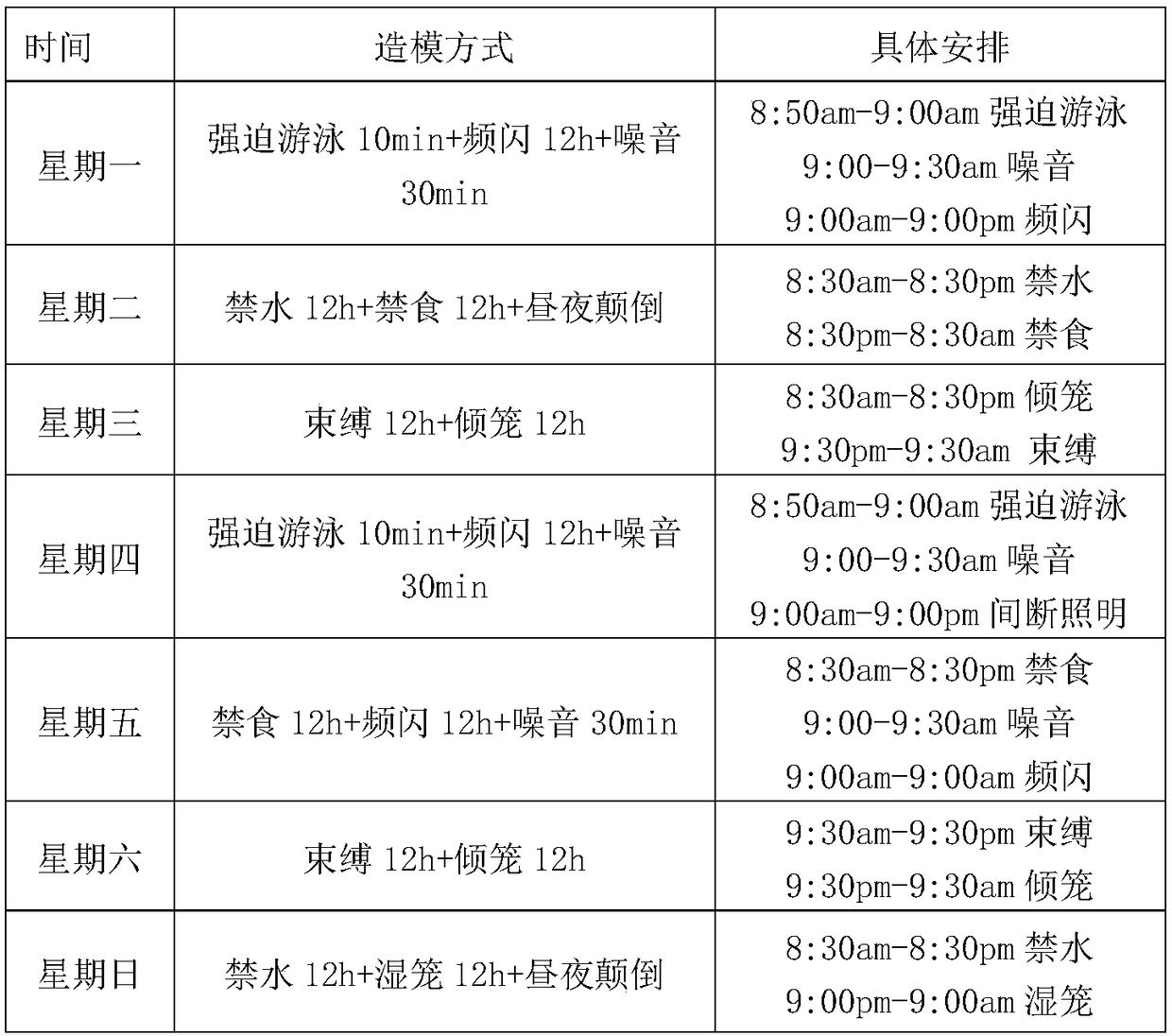

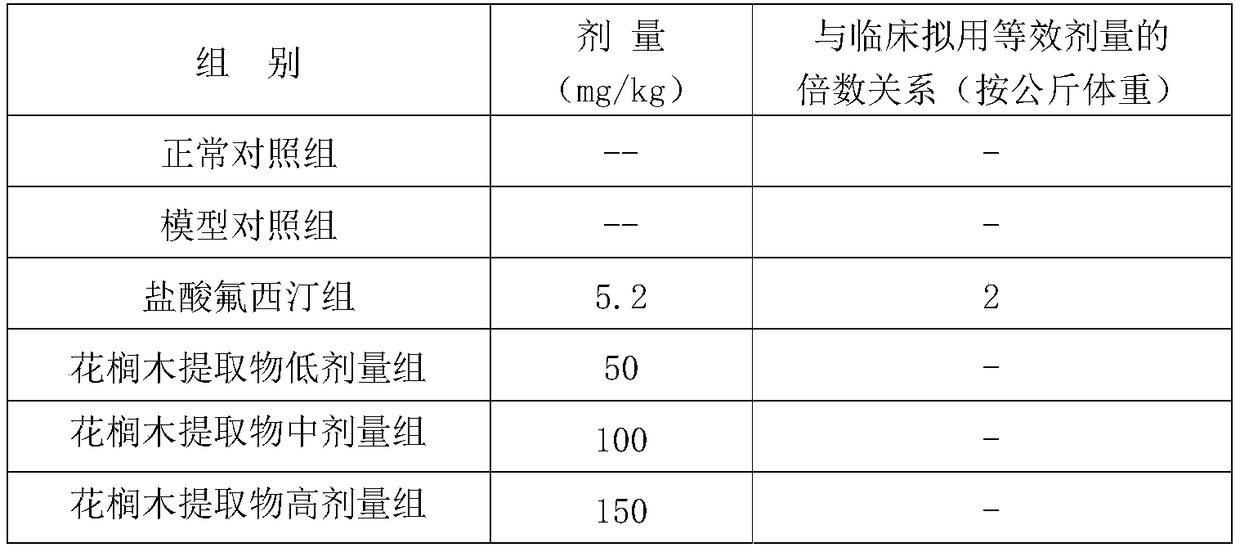

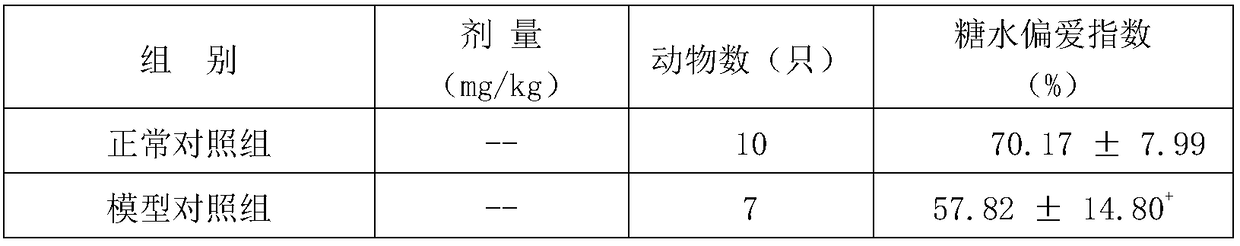

Method used

Image

Examples

Embodiment 1

[0014] The preparation of embodiment 1 flower palm wood leaf extract

[0015] Take 1000g of dry palm leaves raw material, crush them, add ethanol to the crushed leaves at 30°C for 3 times at 30°C according to the ratio of 1g of leaves plus 12mL of ethanol with a mass concentration of 70%, After 30 minutes, the extracts were suction-filtered and combined, and the ethanol was recovered under reduced pressure at 55°C to obtain 2L of an aqueous solution; then the aqueous solution was extracted with petroleum ether until the ether layer was colorless, the petroleum ether layer was discarded, the pH of the aqueous layer was adjusted to 3, and the pH of the aqueous layer was adjusted to 3. The flow rate of 4BV / h passes through the chromatographic column equipped with 800ml AB-8 macroporous adsorption resin. Elute at a flow rate of 3-4BV / h, collect the eluate, recover ethanol under reduced pressure at 55°C, and then freeze-dry to obtain the extract of the leaves of the flower palm.

Embodiment 2

[0016] The preparation of embodiment 2 flower palm wood leaf extract

[0017] Take 1000 g of dry palm leaves raw material, crush them, add ethanol to the crushed leaves at 35°C for 3 times at 35°C according to the ratio of 1 g of leaves plus 10 mL of ethanol with a mass concentration of 70%, After 30 minutes, the extracts were suction-filtered and combined, and ethanol was recovered under reduced pressure at 50°C to obtain an aqueous solution; then the aqueous solution was extracted with petroleum ether until the ether layer was colorless, the petroleum ether layer was discarded, the pH of the aqueous layer was adjusted to 2.5, and the pH of the aqueous layer was adjusted to 2.5. The flow rate of / h passes through the chromatographic column equipped with 800ml AB-8 macroporous adsorption resin, after loading the sample, let it stand for 30min, wash it with water until the effluent is colorless, then use 4000ml mass concentration of 70% ethanol with 3 Elute at a flow rate of -4...

Embodiment 3

[0018] The preparation of embodiment 3 flower palm wood leaf extract

[0019] Take 1000 g of dry palm leaves raw material, crush them, and add ethanol to the crushed leaves at 25°C for 3 times at 25° C. After 30 minutes, the extracts were suction-filtered and combined, and the ethanol was recovered under reduced pressure at 52°C to obtain an aqueous solution; then the aqueous solution was extracted with petroleum ether until the ether layer was colorless, the petroleum ether layer was discarded, the pH of the aqueous layer was adjusted to 3.5, and the pH of the aqueous layer was adjusted to 3.5. The flow rate of / h passes through the chromatographic column equipped with 800ml AB-8 macroporous adsorption resin, after loading the sample, let it stand for 30min, wash it with water until the effluent is colorless, then use 4000ml mass concentration of 70% ethanol with 3 Elute at a flow rate of -4BV / h, collect the eluate, recover ethanol under reduced pressure at 52°C, and then fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com