Production method and device for reducing sulfite residues in frozen shrimp meat

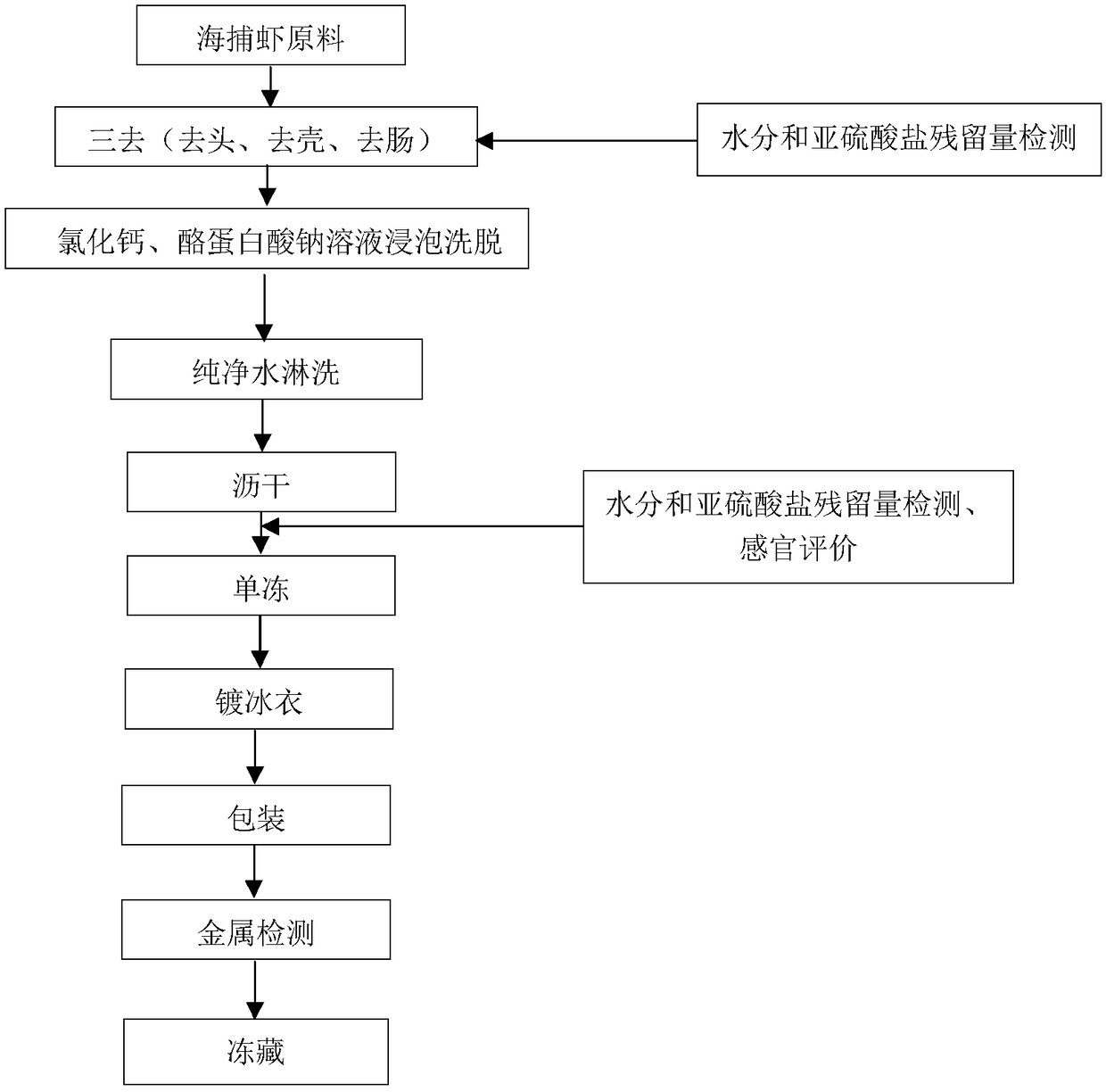

A production method and sulfite technology are applied in the field of production and devices for reducing sulfite residues in frozen shrimp, can solve problems such as large water consumption, poor product quality, low desulfurization efficiency, etc., and achieve convenient operation and low residual content. , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

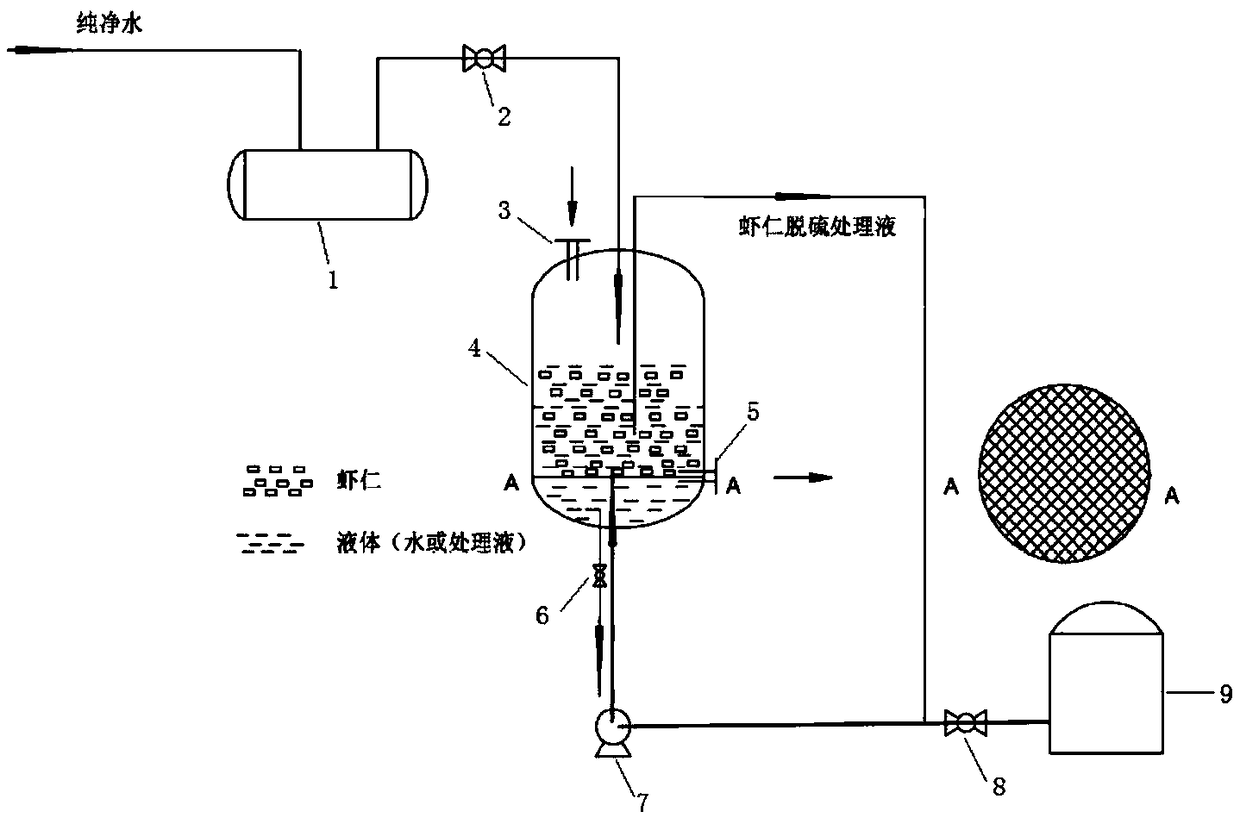

Method used

Image

Examples

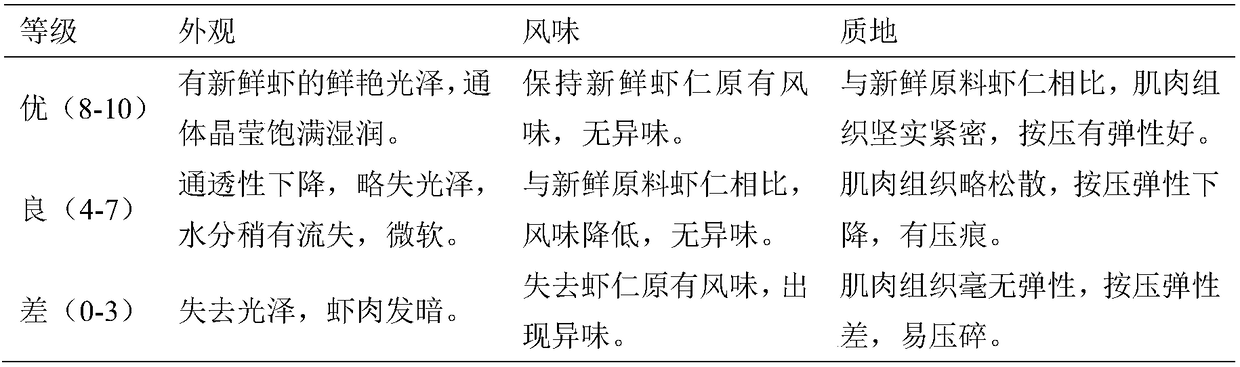

Embodiment 1

[0049] 0.2% food-grade sodium caseinate and 0.05% food-grade calcium chloride mixed solution (dissolved in 2°C ice water), prepared with desulfurization liquid batching tank, open the first valve, 1:3 (shrimp and mixed solution ratio , W / W) desulfurization mixed solution is pumped into the desulfurization treatment tank from the bottom screen, close the first valve → 500kg sea-caught shrimp raw materials → remove the head, shell, and intestine → put the pumped liquid from the feeding port The desulfurization treatment tank → open the desulfurization liquid circulation treatment for 10 minutes → open the third valve, drain the mixed solution to the waste water treatment pipeline → open the second valve, and rinse the shrimp on the sieve plate with pure water (2 times the water volume, W / W), close the second valve, the eluent flows into the waste water treatment pipeline through the lower part → drain for 10 minutes → artificially discharge the shrimp → take a sample, measure th...

Embodiment 2

[0052] 0.2% food-grade sodium caseinate and 0.1% food-grade calcium chloride mixed solution (dissolved in 2°C ice water), prepared with a desulfurization liquid batching tank, open the first valve, 1:4 (shrimp to mixed solution ratio , W / W) desulfurization mixed solution is pumped into the desulfurization treatment tank from the bottom screen, close the first valve → 500kg sea-caught shrimp raw materials → remove the head, shell, and intestine → put the pumped liquid from the feeding port The desulfurization treatment tank → open the desulfurization liquid circulation treatment for 5 minutes → open the third valve, drain the mixed solution to the waste water treatment pipeline → open the second valve, and rinse the shrimp on the sieve plate with pure water (2 times the water volume, W / W), close the second valve, the eluent flows into the waste water treatment pipeline through the lower part → drain for 10 minutes → artificially discharge the shrimp → take a sample, measure the...

Embodiment 3

[0055] 0.3% food-grade sodium caseinate and 0.1% food-grade calcium chloride mixed solution (dissolved in 2°C ice water), prepared with desulfurization liquid batching tank, open the first valve, 1:5 (the ratio of shrimp to mixed solution , W / W) desulfurization mixed solution is pumped into the desulfurization treatment tank from the bottom screen, close the first valve → 500kg sea-caught shrimp raw materials → remove the head, shell, and intestine → put the pumped liquid from the feeding port The desulfurization treatment tank → open the desulfurization liquid circulation treatment for 10 minutes → open the third valve, drain the mixed solution to the waste water treatment pipeline → open the second valve, and rinse the shrimp on the sieve plate with pure water (3 times the water volume, W / W), close the second valve, the eluent flows into the waste water treatment pipeline through the lower part → drain for 15min → artificially discharge the shrimp → take a sample, measure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com